Installing a central AC system isn’t just about connecting a few wires and flipping a switch. In my 15+ years of working with Goodman systems, I’ve seen installs done right—and installs done wrong. The difference comes down to details at every step.

In this guide, I’ll walk you through what I personally look for when setting up a Goodman 2.5 Ton 13.8 SEER2 Northeast System (condenser model GLXS3BN3010 + air handler model AMST30BU1300). Whether you’re a homeowner trying to understand the process or a DIYer who wants to know what a pro checks, this is your roadmap.

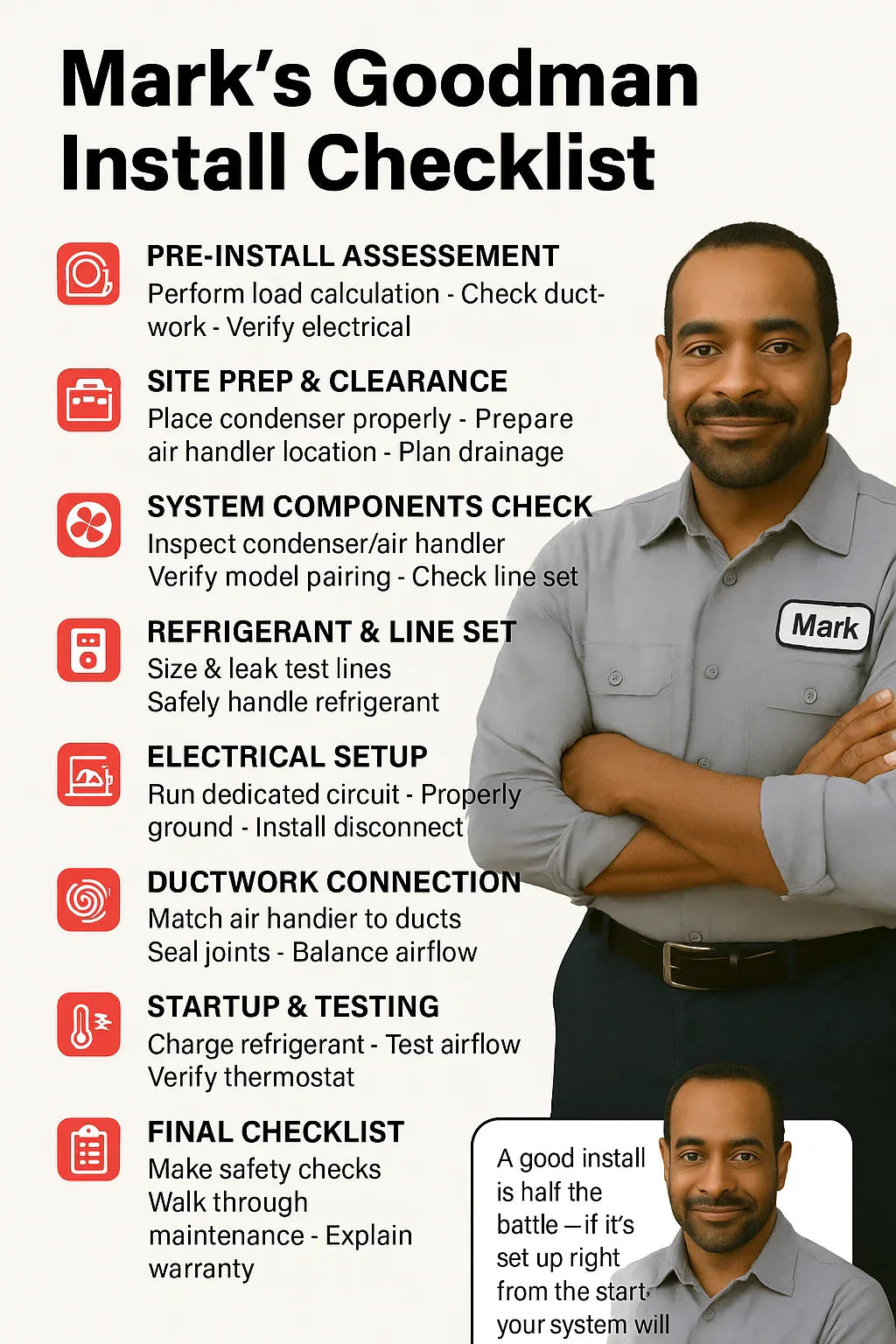

📋 Step 1: Pre-Install Assessment

Before I even bring equipment inside, I run a full pre-install check.

🔍 Load Calculation (Manual J)

-

A 2.5-ton system = 30,000 BTUs/hour, but that doesn’t mean it’s right for every home.

-

I use Manual J software to account for insulation, window types, sun exposure, and occupancy.

-

If the load comes back closer to 24,000 BTUs, I may recommend a 2-ton instead. Oversizing is just as bad as undersizing.

👉 Homeowners: If your installer doesn’t mention Manual J, that’s a red flag.

Learn more about Manual J from ACCA

📐 Ductwork Evaluation

-

I measure existing ducts to ensure they can move 400 CFM per ton (about 1,000 CFM for a 2.5-ton system).

-

Undersized or leaky ducts kill efficiency.

-

I also check for insulation around ducts in unconditioned spaces (attics, basements).

⚡ Electrical Panel Check

-

Goodman’s 2.5-ton condenser usually needs a 25–30 amp breaker.

-

I make sure the home’s electrical panel has capacity and meets NEC code.

🧹 Step 2: Site Prep & Clearance

Next up is prepping the install site.

🏡 Outdoor Condenser Placement

-

Needs to sit on a level pad (concrete or composite).

-

Minimum 12–18 inches clearance from walls, and 5 feet above the unit for airflow.

-

Away from dryer vents or roof drip lines.

🗄️ Indoor Air Handler Placement

-

Basements, attics, or utility closets work fine—but I always check for service clearance.

-

Goodman recommends at least 24 inches in front for servicing filters and coils.

💧 Drainage Setup

-

Condensate line must slope downward and exit safely.

-

In basements, I often add a condensate pump to lift water to a drain.

📦 Step 3: System Components Check

When the equipment arrives, I don’t assume it’s perfect.

📦 Inspection for Damage

-

I check fins on the condenser coil for dents.

-

Verify that blower motor and fan spin freely.

✅ Model Verification

-

Always confirm that the condenser (GLXS3BN3010) matches the air handler (AMST30BU1300).

-

Goodman’s systems are AHRI-rated when properly paired.

🛤️ Line Set Planning

-

Goodman 2.5-ton units typically use a 3/4” suction line and 3/8” liquid line.

-

I measure the distance between indoor and outdoor units—longer than 25 feet may need charge adjustment.

❄️ Step 4: Refrigerant & Line Set Considerations

This is where I see a lot of mistakes from inexperienced installers.

🔧 Proper Sizing

-

If lines are too small, friction loss reduces efficiency.

-

If too large, oil return issues can damage the compressor.

💨 Leak Testing

-

I pressurize with dry nitrogen to at least 150 psi and check all brazed joints with soap bubbles.

⚠️ Refrigerant Handling

-

Goodman 13.8 SEER2 systems typically use R-410A, though R-32 variants are rolling out.

-

Charging must follow superheat/subcooling method—not guesswork.

🔌 Step 5: Electrical Setup

📏 Circuit Requirements

-

Most Goodman 2.5-ton condensers draw 14–18 amps.

-

A dedicated 240V circuit with 25–30A breaker is standard.

🛑 Disconnect Box

-

NEC code requires an accessible disconnect within sight of the condenser.

-

I install a weatherproof fused or non-fused disconnect.

🌎 Grounding

-

Ground wire is checked with a continuity tester.

-

Loose or missing grounds are a shock hazard.

🌬️ Step 6: Ductwork Connection

Even the best system fails if ductwork is sloppy.

📦 Matching Supply & Return

-

Air handler needs proper plenum sizing for balanced airflow.

-

I seal connections with mastic, not duct tape (which dries out).

📊 Air Balancing

-

I check airflow with an anemometer. Target is 350–400 CFM per ton.

-

Rooms farthest from the air handler often need damper adjustments.

🔑 Step 7: Startup & Testing

This is the moment of truth.

🌡️ Refrigerant Charge

-

I use digital gauges to measure subcooling (10–15°F) and superheat (8–12°F).

-

Adjust charge as needed per Goodman’s spec sheet.

🌬️ Airflow Testing

-

A 2.5-ton system should move about 1,000 CFM total.

-

Static pressure must stay below Goodman’s limits (usually 0.5 inches WC).

📉 Electrical Measurements

-

Verify amperage draw matches the nameplate.

-

Low amps = undercharge, high amps = restriction or overcharge.

📱 Thermostat Verification

-

I run the thermostat through a full cycle to confirm cooling/heating switchovers.

📑 Step 8: Final Checklist for Homeowners

Before I leave, I walk the homeowner through the system.

-

Filter location & replacement frequency (every 1–3 months).

-

Thermostat programming for efficiency.

-

Warranty registration with Goodman (must be done within 60 days).

-

Maintenance reminders: coil cleaning, drain line flush, annual check-ups.

👉 Homeowners who follow this see their systems last 15–20 years with minimal issues.

🧰 Mark’s Pro Tips for Goodman Installs

-

Level the condenser pad carefully. A tilted unit stresses the compressor.

-

Don’t rush line set brazing. A bad joint can leak within a year.

-

Seal ducts with mastic, not tape. Air leaks are the #1 efficiency killer.

-

Check airflow twice. Many installs fail because airflow isn’t verified.

-

Educate the homeowner. A system is only as good as its upkeep.

✅ Bottom Line: How Goodman Installs Should Be Done

A Goodman 2.5 Ton 13.8 SEER2 system is built to deliver reliable, efficient comfort in Northeast homes—but only if installed right.

-

Pre-install checks ensure the system is properly sized.

-

Clearances, ductwork, and refrigerant charge determine efficiency.

-

Final homeowner walkthrough guarantees long-term satisfaction.

👉 In my book, half the battle is installation quality. A well-installed 13.8 SEER2 Goodman can outperform a poorly installed 16 SEER2 any day.

In the next topic we will know more about: Cost Breakdown: Equipment, Labor & Long-Term Savings with a 2.5 Ton Goodman System