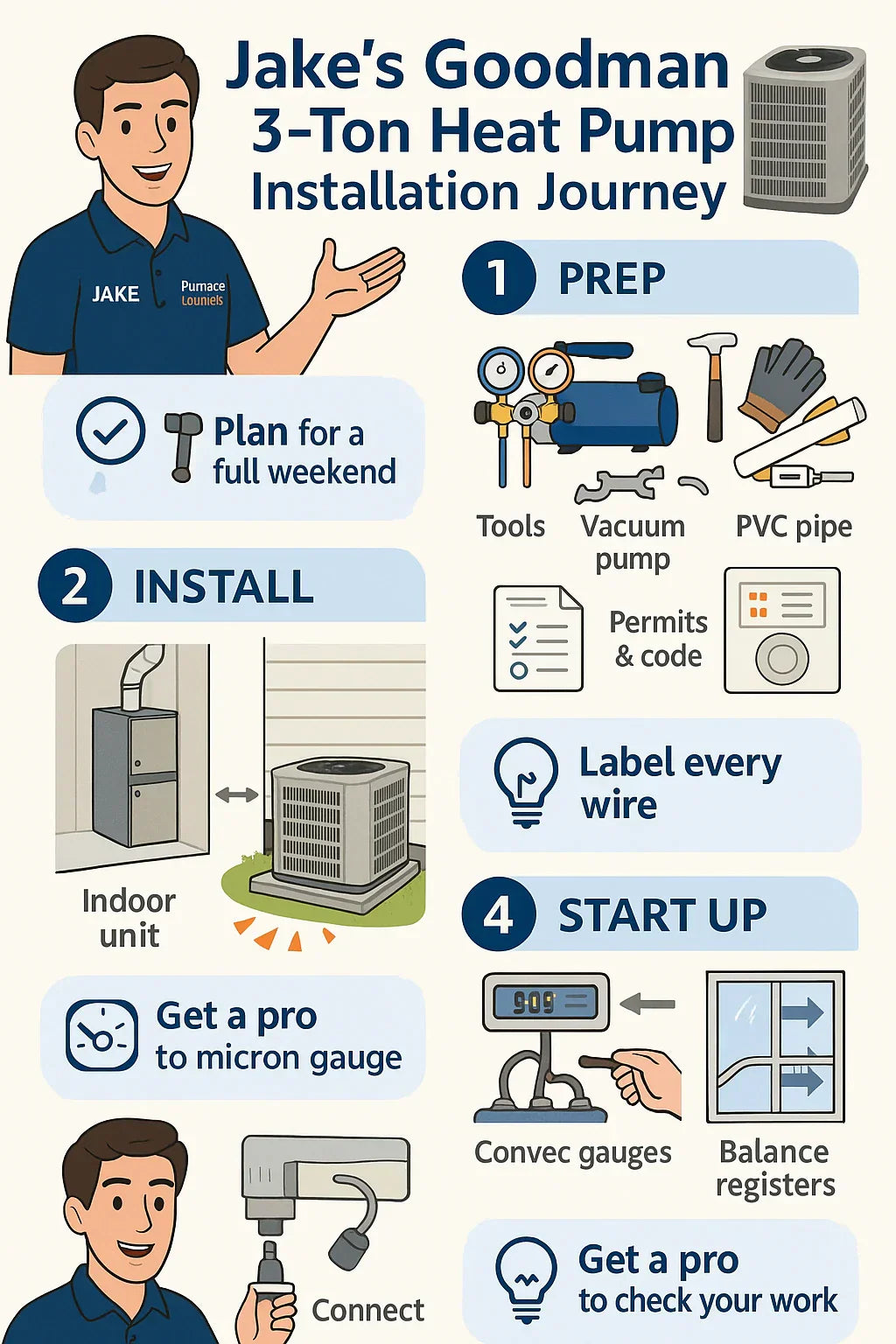

When I first decided to replace my old air conditioner with a 3-ton Goodman 15 SEER2 heat pump system, I thought I was just signing up for an upgrade in comfort and efficiency.

But the real lesson? Installing a heat pump is about planning, precision, and patience.

In this guide, I’ll walk you through every stage of my installation — what I did right, what I’d do differently, and the key insights every homeowner should know before starting a similar project.

🏁 1. Why I Installed My Own Goodman System

I’d been wanting to upgrade to a heat pump for years. My old split system was inefficient and noisy, and my winter gas bills were getting out of hand. Goodman’s 3-ton 15 SEER2 heat pump caught my attention because it offered the perfect mix of performance, value, and reliability — especially paired with the AMST36CU1300 vertical air handler.

A few reasons I tackled the project myself:

-

I already had some HVAC experience (I’d done minor repairs and filter replacements).

-

The Goodman system is DIY-friendly with clear installation guides and color-coded wiring.

-

I wanted to understand every part of my system for future maintenance.

That said, I’ll be honest: there are parts of this install best left to a licensed HVAC professional — especially electrical and refrigerant work. I’ll note those along the way.

🧰 2. Pre-Installation Prep: Tools, Permits & Safety

Before I touched a single wrench, I made a plan. A good installation starts with preparation.

🧾 Tools & Supplies Checklist

Here’s what I used:

HVAC tools:

-

Vacuum pump (for line evacuation)

-

Micron gauge

-

Manifold gauge set (R-410A compatible)

-

Torque wrench

-

Tubing cutter and flaring tool

-

Nitrogen tank and regulator (for brazing purge)

-

Brazing torch and safety goggles

Electrical & general tools:

-

Multimeter

-

Wire strippers and crimpers

-

Conduit bender

-

Level and stud finder

-

PVC glue and fittings for the drain

-

Cordless drill with hole saw

Safety gear:

-

Safety glasses

-

Work gloves

-

Steel-toed boots

-

Ear protection

Pro tip: Label your tools by function — electrical, refrigerant, or ductwork. It saves you constant trips back and forth.

🪪 Permits & Code Checks

Before doing anything major, I checked my local HVAC permit requirements. Some areas let you replace existing equipment without a permit, but most require at least a mechanical and electrical inspection.

I also reviewed the U.S. Department of Energy’s Heat Pump Installation Guidance to understand code compliance for line sizing, breaker ratings, and disconnect placement.

🧹 Site Preparation

I set my outdoor unit pad in a shaded but open space, ensuring:

-

Clearance: At least 24 inches on all sides for airflow.

-

Elevation: 8 inches above grade to avoid snow and water buildup.

-

Level base: Concrete pad with rubber vibration dampers.

Inside, I measured the utility closet for my vertical air handler — allowing at least 3 inches clearance on each side for service access.

📦 3. Unboxing the Goodman System

When my Goodman system arrived, I checked everything before signing off delivery.

The condenser (Model GLZS4BA3610) was packed securely, with protective corners and foam inserts. The air handler (Model AMST36CU1300) came with mounting brackets, drain fittings, and a wiring diagram attached to the inside panel.

What’s in the box:

-

Factory-charged outdoor unit (R-410A refrigerant)

-

Air handler with multi-speed blower

-

User manual & wiring schematic

-

Warranty registration card

-

PVC drain adapter

-

Mounting and leveling brackets

💡 Tip: Always match serial numbers on your equipment and warranty registration. It ensures coverage if a component fails later.

For reference, Goodman’s installation manuals were invaluable during setup.

🪜 4. Installing the Indoor Air Handler

The air handler is the core of your home’s airflow system. Mine was a vertical upflow configuration, feeding conditioned air into a supply plenum that connects to existing ducts.

Step 1: Positioning & Leveling

I set the air handler on a vibration pad and verified it was perfectly level with a spirit level. This prevents condensate pooling.

Step 2: Ductwork Connections

I attached the supply plenum (top outlet) and return duct (bottom inlet) using foil-backed mastic tape and screws.

Any small air leaks here reduce efficiency, so I sealed all joints carefully.

Step 3: Condensate Drain

Using ¾-inch PVC pipe, I installed the primary drain line with a ¼-inch per foot slope toward the floor drain.

A secondary overflow line was routed separately for safety.

Step 4: Electrical Wiring

The air handler connects to a 240V breaker. I ran conduit and used proper strain reliefs at all entry points.

Low-voltage (24V) thermostat wires connect to the board labeled “R,” “Y,” “G,” “O,” “C.”

Pro Tip: Leave extra slack for future servicing and label both ends of each wire.

For wiring standards and safety, the Electrical Safety Foundation International is a great resource.

🌬️ 5. Setting the Outdoor Condenser

This was where things got real — the outdoor unit installation determines not just performance but also longevity.

Step 1: Choose the Right Location

I placed the unit on the northeast side of my house, avoiding direct afternoon sunlight.

The spot had:

-

No obstructions (like fences or shrubs).

-

Adequate airflow around all sides.

-

Short line set distance (~20 feet) to minimize efficiency loss.

Step 2: Mounting the Condenser

I bolted the unit to my pre-leveled concrete pad using stainless steel anchors and vibration pads.

Step 3: Routing the Line Set

I drilled a 3-inch hole through the wall using a hole saw, lined it with a sleeve, and ran the insulated copper line set through to the air handler.

Pro Tip: Protect insulation from UV rays with a line cover kit.

For reference, EnergyStar’s Heat Pump Installation Checklist shows proper clearance and mounting diagrams.

⚙️ 6. Refrigerant Line & Electrical Connections

A. Refrigerant Lines

My Goodman condenser came pre-charged with R-410A for up to 15 feet of line. Since my run was 20 feet, I confirmed additional charge per Goodman’s specs.

Steps I followed:

-

Cut lines to length using a tubing cutter.

-

Deburred ends and flared them to 45°.

-

Connected suction and liquid lines using torque wrench to manufacturer torque specs.

-

Pressure-tested with nitrogen to 300 psi for 30 minutes.

💡 Pro Tip: Always use nitrogen during brazing to prevent internal oxidation.

B. Electrical

-

High-voltage: 240V circuit from disconnect box to outdoor unit.

-

Low-voltage: 24V control wire from air handler.

I grounded both systems according to ASHRAE electrical standards and verified continuity with a multimeter.

🧊 7. Vacuum, Charging & Leak Testing

Now came one of the most crucial steps — evacuating air and moisture from the refrigerant lines.

Step 1: Evacuation

Using my vacuum pump and micron gauge, I pulled a deep vacuum down to 500 microns and held it steady for 15 minutes.

If it rises, you’ve got a leak. Luckily, mine stayed stable.

Step 2: Release Factory Charge

Once confirmed leak-free, I opened both service valves on the condenser to release refrigerant into the system.

Step 3: Verify System Pressure

I checked suction and discharge pressures using my manifold gauge — they were within Goodman’s spec table for 75°F ambient.

For best practices, check out HVAC School’s Vacuum Guide — it’s gold for first-timers.

⚡ 8. System Startup & Configuration

The moment of truth.

I restored power at the breaker, set my thermostat to Cool Mode, and watched the system come alive. The outdoor fan spun smoothly, and within minutes, cool air flowed from my registers.

Startup Checklist

-

✅ Airflow direction verified

-

✅ Suction pressure: 125 psi

-

✅ Discharge pressure: 325 psi

-

✅ Supply/Return delta-T: 17°F

-

✅ Condensate drain flowing freely

Then I switched to Heat Mode — the reversing valve clicked, and warm air poured in. Success.

Pro Tip: Always monitor amperage draw against nameplate rating. My condenser label said 17.2A max; I measured 16.6A — perfect.

🧽 9. Cleanup & Final Details

After confirming stable operation, I sealed every wall penetration with expanding foam and caulk. I also labeled:

-

Disconnect box

-

Breakers

-

Refrigerant lines (“suction,” “liquid”)

-

Drain lines (“primary,” “secondary”)

I then registered my product online with Goodman for the 10-year limited warranty — a must for coverage.

I also logged all readings, refrigerant charge, and serial numbers for my records — this helps with rebates and maintenance later.

🧠 10. Lessons Learned

Here’s the truth: Installing a heat pump isn’t rocket science, but it requires discipline and attention to detail. Here’s what stood out most from my experience.

Lesson 1: Prep Time > Install Time

I spent more time planning and laying out materials than actually installing. It paid off — fewer mistakes and zero backtracking.

Lesson 2: Don’t Skimp on Tools

A cheap vacuum pump or leaky gauges can ruin a perfect installation. Invest once in quality gear.

Lesson 3: Understand the System, Don’t Just Assemble It

Knowing how the reversing valve, defrost cycle, and blower speeds interact makes you a smarter homeowner.

Goodman’s manuals and EnergySage’s sizing guide helped me understand real-world performance.

Lesson 4: Airflow Is Everything

If ducts aren’t sealed or the filter is clogged, even the most efficient heat pump underperforms. I learned to measure static pressure — a detail many DIYers skip.

Lesson 5: The Value of Professional Input

Even though I did most of the install myself, I hired a certified HVAC tech for final pressure checks and startup confirmation. It cost me $150 — well worth the peace of mind.

📈 Results: Comfort, Noise & Efficiency

After the first week, I was genuinely impressed.

-

Cooling: My home hit target temps faster and held them steadier.

-

Noise: The outdoor unit was whisper-quiet — about 55 dB measured.

-

Efficiency: Based on my smart thermostat data, energy use dropped by 25% compared to my old SEER 13 system.

-

Comfort: Airflow was smoother and less “drafty.”

The Goodman 3-ton unit really hit the sweet spot for my 2,000 sq ft home.

🧾 Maintenance Plan

Here’s the maintenance schedule I now follow to protect my investment:

| Task | Frequency | Notes |

|---|---|---|

| Replace air filter | Every 3 months | Use MERV 8–10 pleated filter |

| Inspect coils | Every 6 months | Clean with fin comb & coil cleaner |

| Flush condensate drain | Annually | Prevent algae buildup |

| Check refrigerant pressure | Annually | Done by a licensed tech |

| Clean outdoor unit | Spring & Fall | Remove debris and hose gently |

| Verify thermostat calibration | Annually | Prevents short-cycling |

Proper maintenance keeps efficiency high and avoids costly repairs.

💡 Jake’s Key Installation Tips Recap

-

Plan your install weekend: I budgeted two full days but finished in 1½.

-

Document everything: photos, wire labels, pressure readings.

-

Never skip vacuuming: moisture + refrigerant = acid inside your compressor.

-

Double-check power polarity: miswiring can fry control boards.

-

Seal ducts and penetrations: small leaks equal big energy waste.

-

Call a pro for final charge verification: even small refrigerant errors impact performance.

🌎 Environmental & Cost Benefits

Choosing a heat pump wasn’t just about comfort. I wanted a cleaner, more sustainable way to heat and cool my home.

-

Reduced carbon footprint: No fossil fuel combustion, just electricity and refrigerant.

-

Energy savings: My estimated annual utility cost dropped by 20–30%.

-

Tax credits: Under the Inflation Reduction Act, many homeowners can claim up to $2,000 for installing high-efficiency heat pumps

The long-term value makes Goodman’s investment even smarter.

🏠 The Final Verdict

Installing my Goodman 3-ton 15 SEER2 heat pump taught me more than I expected.

It wasn’t just about hooking up pipes or wires — it was about understanding airflow, pressure, safety, and design.

Today, I enjoy a quieter, cleaner, and more efficient home system that I helped install myself.

If you’re considering doing the same, take it from me: plan carefully, follow the manual, and don’t be afraid to ask for help when needed.

And remember — whether you DIY or hire a pro, a Goodman system rewards the homeowner who respects the process.

In the next topic we will know more about: How Efficient Is the Goodman 15 SEER2 Heat Pump? Real-World Energy Savings