When Tony decided to replace the old wall unit in his guest apartment, he faced a choice many homeowners run into: Should I install this PTAC (Packaged Terminal Air Conditioner) myself, or should I call a professional?

On the surface, a PTAC looks simple—just a self-contained system you slide into the wall. But once Tony started researching, he realized there’s more to it: electrical wiring, wall cutting, sealing, and safety concerns.

Amana Distinctions Model 12,000 BTU PTAC Heat Pump with 3.5 kW Electric Heat Backup

This guide breaks down what a PTAC installation involves, what tools you’ll need, the risks of DIY, and when it’s smart to bring in a pro.

🔍 What Is a PTAC and How Is It Installed?

A PTAC (Packaged Terminal Air Conditioner) is the type of heating and cooling unit you often see in hotels and apartments. It’s a self-contained system designed to slide into a wall sleeve and provide both heating and cooling in one package.

-

Size: Standard PTACs fit a 42" x 16" wall sleeve.

-

Operation: Many modern PTACs (like the Amana Distinctions 12,000 BTU model) offer heat pump heating with electric backup.

-

Power: Most units require a 208/230V dedicated circuit, which is more powerful than a standard 110V outlet.

👉 Unlike window ACs, PTACs are permanent installations, meaning once you cut a hole in your wall, you’re committed.

Reference: Amana PTAC Installation Guides.

🧰 Tools & Materials Needed for DIY

Before Tony started, he made a checklist of everything needed to install a PTAC:

Basic Tools

-

Tape measure & level

-

Stud finder

-

Circular saw or reciprocating saw (for wall opening)

-

Drill + masonry bits (if brick/concrete wall)

-

Screwdrivers & wrench set

Electrical Tools

-

Voltage tester

-

Wire cutters/strippers

-

Access to breaker panel (for 208/230V wiring)

Materials

-

PTAC unit

-

PTAC wall sleeve (42" x 16")

-

Exterior grille

-

Insulation & weatherproof caulk

-

Mounting brackets (if required)

👉 Tony’s Tip: “Don’t start cutting into the wall until you have the sleeve and unit on site. PTAC dimensions can vary slightly by brand.”

🛠️ Step-by-Step DIY PTAC Installation

If you’re handy and confident with electrical work, here’s how the process looks:

1. 📍 Choose Location

-

Pick a wall with clear outdoor airflow (no obstructions).

-

Ensure no studs, plumbing, or wiring block the opening.

-

Ideal height: 6–12 inches above the floor.

2. ✂️ Cut Wall Opening

-

Measure sleeve dimensions precisely (usually 42" wide x 16" high).

-

Cut through drywall, insulation, and exterior wall materials.

-

Install proper framing around the cut for structural support.

3. 📦 Install Wall Sleeve

-

Slide the sleeve into the wall opening.

-

Use a level to ensure proper alignment (critical for drainage).

-

Secure sleeve to framing.

4. ⚡ Connect Electrical Wiring

-

Run a dedicated 208/230V line from breaker panel.

-

Install proper receptacle or hardwire according to local code.

-

Use a voltage tester before connecting.

👉 Reference: National Electrical Code (NEC) guidelines.

5. 🧩 Insert PTAC Unit

-

Slide the PTAC into the sleeve.

-

Secure with mounting screws.

-

Attach exterior grille for airflow protection.

6. 🧱 Seal & Insulate

-

Apply foam insulation around sleeve.

-

Seal interior and exterior gaps with weatherproof caulk.

7. ✅ Test Operation

-

Turn on breaker.

-

Test cooling, heating, and fan modes.

-

Check for air leaks around sleeve.

⚠️ Safety Concerns & Limitations of DIY

Tony realized some risks right away:

1. Electrical Hazards

-

PTACs use high-voltage power (208/230V).

-

Incorrect wiring can cause fires or electrocution.

2. Structural Risks

-

Cutting into walls without checking load-bearing status can damage framing.

-

Poor sleeve leveling leads to water leaks and mold.

3. Code Compliance

-

Many municipalities require permits for electrical work.

-

Insurance claims may be denied if the PTAC was not installed to code.

👷 When to Call a Pro

Tony is handy, but he knew there are times when calling a professional installer makes sense.

-

Electrical limitations: If you don’t have a 208/230V circuit, an electrician must install one.

-

Multi-story buildings: Cutting into exterior walls above ground is risky.

-

Condensation issues: Pros ensure proper drainage slope to prevent leaks.

-

Building codes: Some states require a licensed HVAC or electrical contractor.

👉 According to HomeAdvisor, the typical cost for professional PTAC installation runs $300–$700, depending on wall modifications and electrical work.

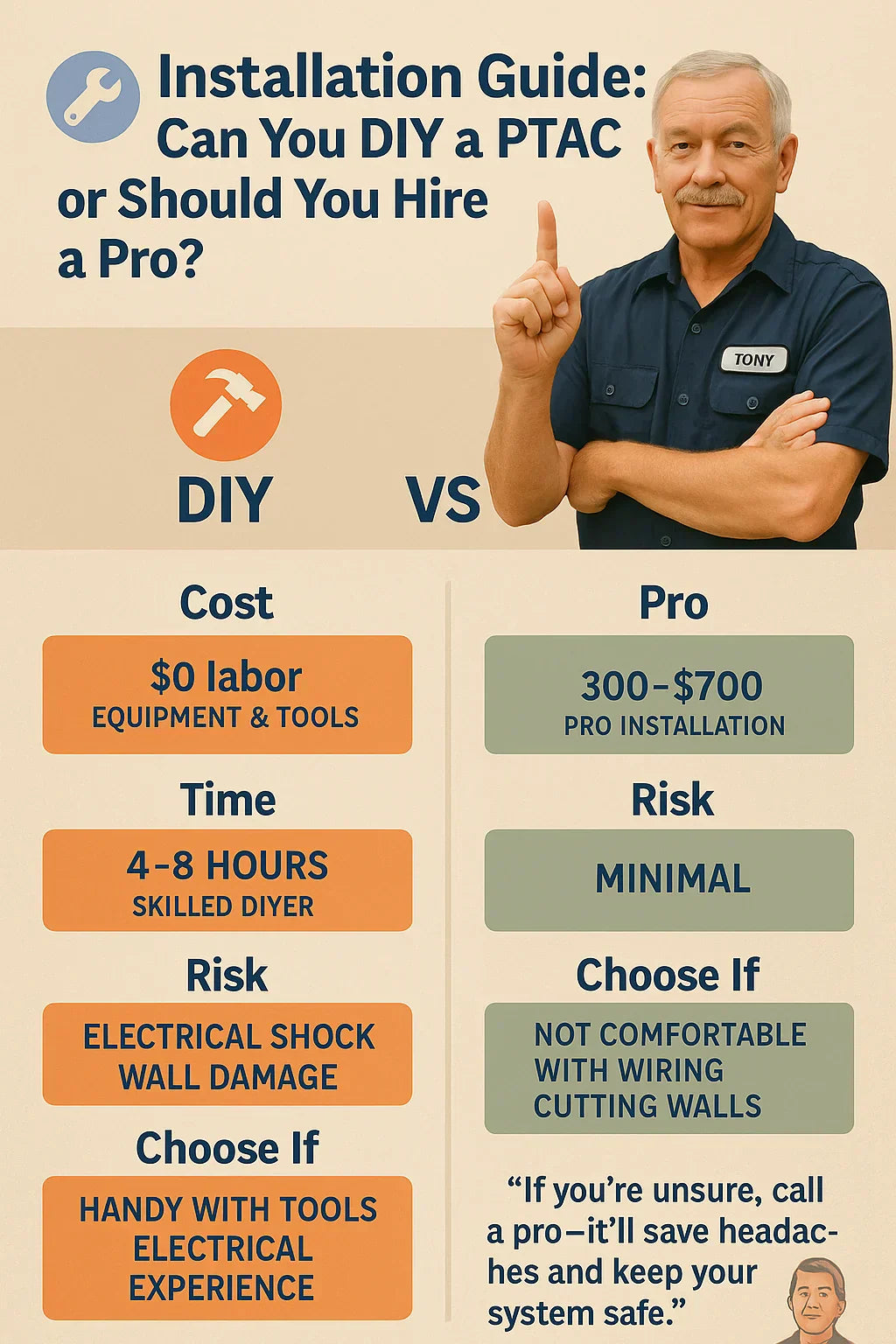

💰 Cost Comparison: DIY vs. Pro Install

| Factor | DIY Install | Pro Install |

|---|---|---|

| Upfront Cost | $0 labor, just tools & materials | $300–$700 labor |

| Risks | Electrical hazards, wall leaks, code violations | Minimal if licensed pro |

| Time | 4–8 hours for skilled DIYer | 2–4 hours for pro |

| Long-Term | May void warranty if improperly installed | Warranty protected |

👉 Tony’s Conclusion: “I saved a few hundred doing the framing and sleeve myself, but I hired an electrician to hook up the wiring. That was worth every penny.”

🧹 Maintenance After Installation

Once installed, keeping your PTAC running smoothly is simple:

-

Monthly: Clean filters.

-

6 Months: Vacuum condenser coils.

-

Annually: Inspect electrical connections and heating coils.

Reference: Amana PTAC Maintenance.

🎯 Final Verdict: DIY or Pro?

-

DIY makes sense if:

-

You’re handy with tools.

-

Comfortable with basic framing & cutting walls.

-

Have prior electrical experience.

-

-

Hire a Pro if:

-

You lack electrical experience.

-

Live in a building with strict codes.

-

Want the peace of mind of warranty compliance.

-

Tony’s advice:

“Installing a PTAC isn’t rocket science, but it’s also not plug-and-play like a window AC. If you’ve never run a 230V line or cut into walls before, hire a pro. If you’re confident and careful, DIY can save you a few hundred bucks.”

In the next topic we will know more about: Noise Levels Explained: How Quiet Is the Amana Distinctions PTAC?