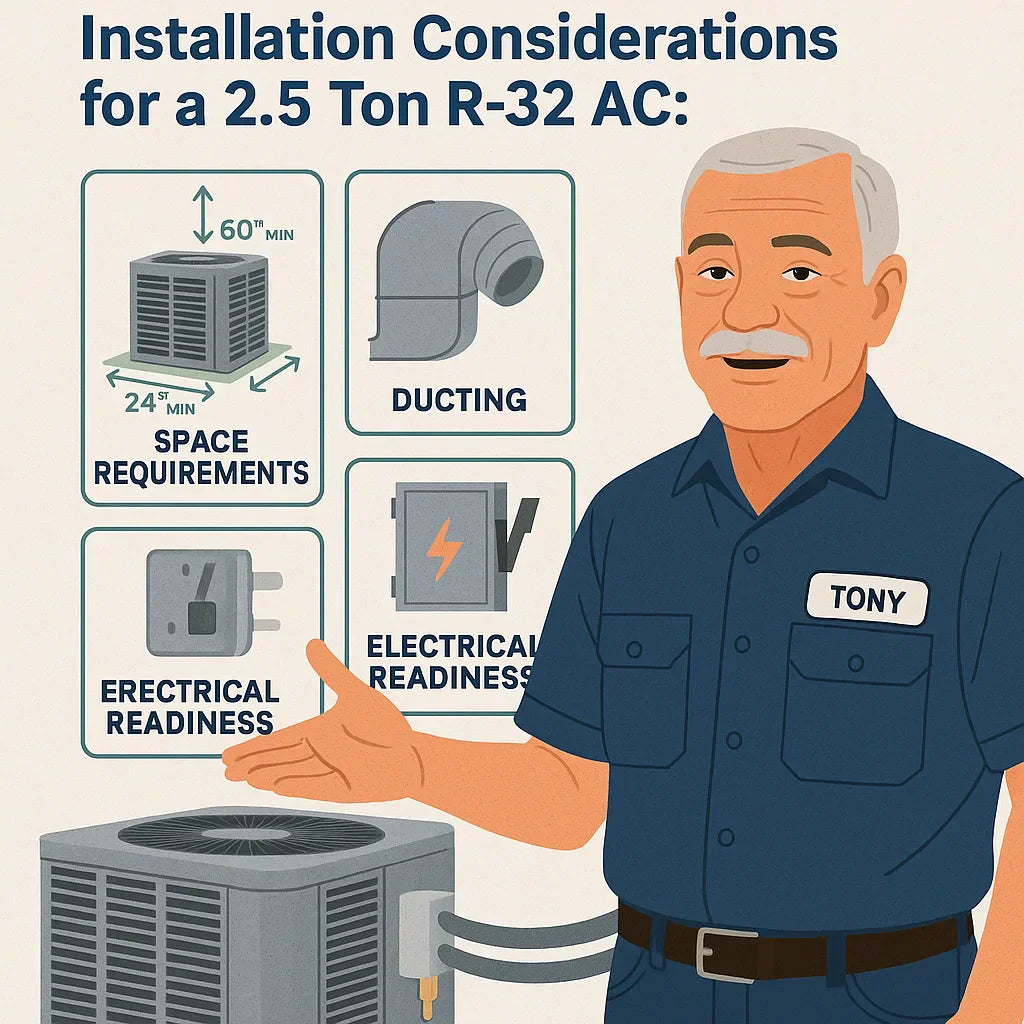

Installing a new 2.5 Ton R-32 AC system isn’t just about buying the right equipment—it’s about making sure your home is ready to support it. If you’re like Tony, a proactive homeowner who likes to plan ahead (and maybe even handle a few tasks himself), this guide walks you through everything you need to know to get installation-ready—from spacing and ductwork to line sets and power requirements.

📏 1. Space Requirements for Indoor & Outdoor Units

🧱 Outdoor Condenser Clearance

-

Footprint: Most 2.5-ton R-32 condensers range from 26" to 36" wide and stand about 30" to 40" tall.

-

Clearance:

-

Minimum 12–24 inches on sides

-

At least 60 inches above for airflow

-

24–36 inches front and rear for service access

-

Avoid placing the unit near dryer vents, gas meters, or under deck overhangs.

🏠 Indoor Air Handler Space

-

Options: Horizontal, vertical (upflow/downflow), or multi-position units

-

Most handlers fit in attics, closets, garages, or crawl spaces

-

Make sure the area has enough space to remove filters and access panels

🌬️ 2. Ducting: Airflow, Sizing & Return Considerations

A 2.5 ton system requires about 1,000 CFM (cubic feet per minute) of airflow. If your ducts are undersized or leaky, the system will underperform—even if the AC unit itself is efficient.

✅ Duct Sizing Guidelines:

-

Main Trunk: 12"–14" diameter round or 8" x 20" rectangular

-

Branch Ducts: 6"–8" diameter for each room

-

Return Air: At least 1.5 square feet of return grille area

🧰 Upgrades to Consider:

-

Reseal old duct joints with mastic

-

Insulate exposed ductwork

-

Add additional returns for open-concept homes

🔌 3. Electrical Requirements: Voltage, Breakers & Wiring

Most 2.5-ton R-32 systems require:

| Component | Spec |

|---|---|

| Voltage | 208/230V single phase |

| Breaker | 20–30 amps (check unit label) |

| Disconnect | Outdoor-rated, within sight of condenser |

| Wire | 10 AWG copper minimum |

⚠️ NEC 2023 Updates:

-

GFCI Protection may now be required on outdoor HVAC equipment

-

Local codes may override federal guidelines, so always check with a licensed electrician

📐 4. Line Set Considerations: Refrigerant Lines for R-32

🧊 Standard Line Sizes:

-

Liquid Line: 3/8"

-

Suction Line: 3/4"

📏 Maximum Length:

-

Most systems allow 25–50 feet of line set without requiring extra charge

⚠️ R-32 Tips:

-

Use refrigerant-grade copper tubing with proper insulation

-

R-32 is slightly flammable (A2L) — so joints must be brazed carefully

-

Avoid kinks and sharp bends

-

Use UV-resistant insulation on suction lines

📦 5. Mounting the Condenser: Pad, Wall Brackets, or Roof

🧱 Mounting Options:

-

Plastic or concrete pad on level ground

-

Wall brackets if ground clearance is needed

-

Roof mounts in urban or flat-roof homes (with vibration dampeners)

🛑 Best Practices:

-

Minimum 6" clearance off ground for snow or debris

-

Use vibration pads to reduce compressor noise

-

Confirm pad won’t shift due to drainage or freeze-thaw cycles

💧 Condensate Drain:

-

Must slope 1/4 inch per foot to exterior or plumbing

-

Secondary drain pan required for attic installs

🌐 6. Ventilation & Add-On Systems

Many homes are upgrading beyond just cooling. Here’s what to consider if you're future-proofing:

🌬️ Optional Add-Ons:

-

Fresh Air Intake Ducts (for tighter homes)

-

ERVs/HRVs for ventilation and humidity control

-

MERV 11+ filters for allergy relief

-

Zoning systems for multistory homes

All of these can impact system sizing and airflow, so plan ahead.

🔧 7. What Can Tony DIY vs. What Needs a Pro?

👨🔧 DIY-Appropriate Tasks:

-

Site prep for condenser pad

-

Installing and sealing ducts

-

Running low-voltage thermostat wire

-

Attic insulation & filter replacement

🛑 Hire a Pro For:

-

Handling refrigerant (EPA 608 required)

-

Brazing and nitrogen purging line sets

-

Charging R-32 systems

-

Electrical panel wiring

-

Pulling permits and passing inspections

Making the switch to R-32 is smart—but being prepared for installation is even smarter. Whether you’re doing some of it yourself or bringing in the pros, these considerations will help you avoid delays, pass inspections, and enjoy your new AC system right away.

In the next topic we will know more about: How Much Does a 2.5 Ton R-32 AC Cost in 2025? Equipment, Labor & Long-Term Value