🌟 Introduction: Why Knowing the Process Matters

Replacing an old HVAC system isn’t just a matter of swapping boxes — it’s a multi-step process that involves proper planning, safe removal, precise installation, and thorough testing.

A 3.5 ton AC with furnace combo is a big investment, and knowing exactly what to expect can save you from:

-

Surprise costs

-

Subpar performance

-

Voided warranties

-

Safety hazards

I’ve broken down the full journey from contractor selection to final inspection so you can be an informed homeowner from day one.

📋 Pre-Installation Preparation

1. Choosing the Right Contractor

-

Verify state licensing and insurance.

-

Look for NATE-certified technicians.

-

Get at least three written estimates for the same scope of work.

2. Manual J Load Calculation

Even though you’re targeting a 3.5 ton system, a good installer will run a Manual J load calculation to confirm it’s the right size.

Factors include:

-

Square footage

-

Insulation levels

-

Window types and orientation

-

Occupancy

-

Local climate

3. Selecting Furnace Type

-

Gas furnace for cold climates and lower heating bills where natural gas is available.

-

Electric furnace for all-electric homes or mild climates.

4. Permits & Scheduling

-

Most jurisdictions require a mechanical permit and sometimes an electrical or gas permit.

-

Coordinate with the contractor to schedule installation when you can be home.

🛠 Removal of Old Equipment

1. Refrigerant Recovery

-

Federal law requires EPA-certified recovery of refrigerant from your old AC system.

-

Your contractor must have Section 608 certification.

📎 Reference: EPA Refrigerant Regulations

2. Dismantling the Furnace

-

Disconnect gas or electric supply.

-

Remove flue pipe (gas models).

-

Disconnect from plenum and return duct.

3. Ductwork Assessment

-

Contractor should inspect for leaks, insulation gaps, and sizing issues.

-

Some ducts may need resizing to handle the airflow of the new system.

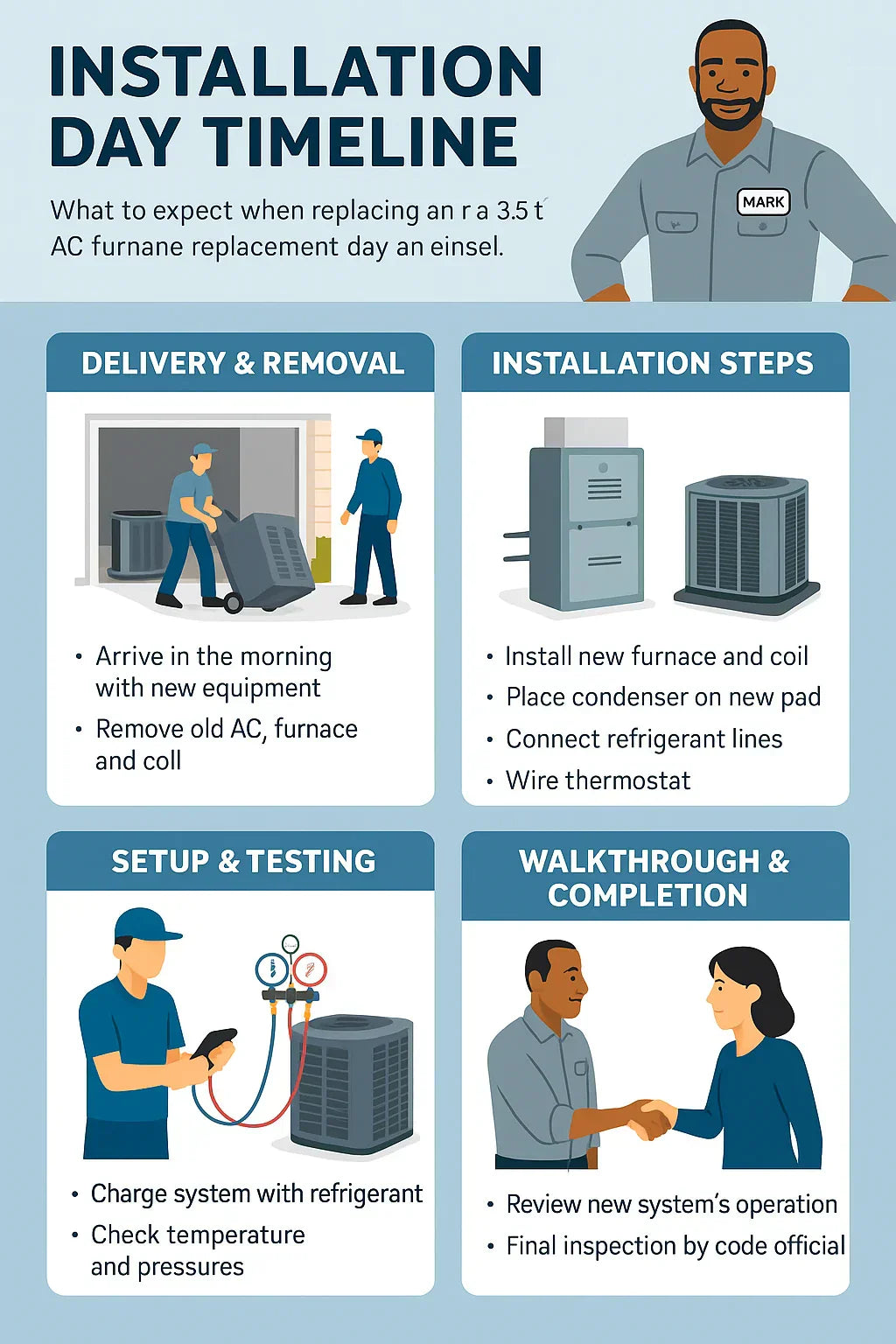

⚙ Installation Day – Step-by-Step

Here’s what happens on installation day for a 3.5 ton AC + furnace:

1. Delivery & Staging

-

New furnace, evaporator coil, condenser, thermostat, and accessories are delivered.

-

Tools, safety gear, and materials organized before starting.

2. Furnace & Coil Installation

-

Furnace positioned to allow service access.

-

Coil installed above (upflow) or below (downflow) furnace in the plenum.

-

Proper sealing with mastic or UL-181 foil tape.

3. Outdoor Condenser Placement

-

Pad leveled and vibration isolation pads used.

-

Minimum clearance from walls and obstructions per manufacturer specs.

4. Refrigerant Line Set

-

Replace old lines when possible.

-

Properly insulated suction line to prevent condensation.

5. Electrical & Thermostat Connections

-

Dedicated circuit for AC and furnace.

-

Low-voltage control wiring connected to thermostat.

-

Smart thermostat installed if included.

🔍 Quality & Code Checks

Before startup, your contractor should run system integrity checks:

-

Leak Testing

-

Pressurize with nitrogen.

-

Use electronic leak detector.

-

-

Airflow Verification

-

Adjust blower speed for correct CFM (cubic feet per minute).

-

Check static pressure against manufacturer’s max rating.

-

-

Combustion Safety (Gas Furnaces)

-

Inspect gas connections for leaks.

-

Verify venting slope and termination.

-

Test CO levels.

-

-

Electrical Safety

-

Confirm breaker sizing and wire gauge.

-

Tighten all lugs and connections.

-

🌡 System Startup & Testing

1. Refrigerant Charging

-

Charge by superheat (fixed orifice) or subcooling (TXV) per manufacturer specs.

-

Verify correct refrigerant type (R-410A or R-32 in new systems).

2. Temperature Split

-

Measure return and supply air temperature.

-

Target: 16–22°F difference for cooling.

3. SEER2 Performance Verification

-

Check amperage draw and operating pressures to ensure efficiency rating is met.

📄 Paperwork & Post-Install Steps

1. Warranty Registration

-

Many manufacturers require online registration within 60–90 days.

2. Permit Inspection

-

Local inspector checks installation for code compliance.

3. Homeowner Orientation

-

How to change filters.

-

Thermostat programming.

-

Maintenance schedule.

✅ Mark’s Pro Tips for a Smooth Install

-

Be Present: Stay home during installation to approve major decisions.

-

Document Everything: Take photos of new equipment model numbers and serial numbers.

-

Ask for a Copy of Load Calculation: It’s your proof that system size is correct.

-

Request a Commissioning Report: Includes test results and refrigerant readings.

📎 Verified External References

✅ Conclusion

A 3.5 ton AC with furnace replacement is one of the most important home upgrades you’ll make. When you understand the installation process, you can:

-

Hold contractors accountable

-

Avoid costly mistakes

-

Ensure your system runs at peak efficiency for years

If you follow this checklist, your installation day will be smooth, safe, and set up for long-term comfort.

In the next topic we will read more about: How to Maintain Your 3.5 Ton AC and Furnace for Maximum Lifespan