🔩 1️⃣ Introduction: Why R-32 Installation Matters in 2025 and Beyond

If you’re planning a new AC or heat pump installation in 2025, there’s one word you’ll keep hearing: R-32.

This new refrigerant is the next chapter in HVAC technology. It replaces older R-410A systems, delivering better efficiency and a smaller carbon footprint — but it also brings new installation rules.

That’s because R-32, while environmentally friendly and energy-efficient, is also a mildly flammable A2L refrigerant. It’s perfectly safe in the right hands — but it must be handled differently.

Best Air Conditioners And Gas Furnace Systems

I’m Jake Lawson, and I’ve installed hundreds of HVAC systems — from R-22 dinosaurs to cutting-edge R-32 heat pumps. In this guide, I’ll walk you through what homeowners need to know before and during installation, what’s safe to DIY, and what to leave to the pros.

📗 Reference: EPA – HFC Phase-Down Rules

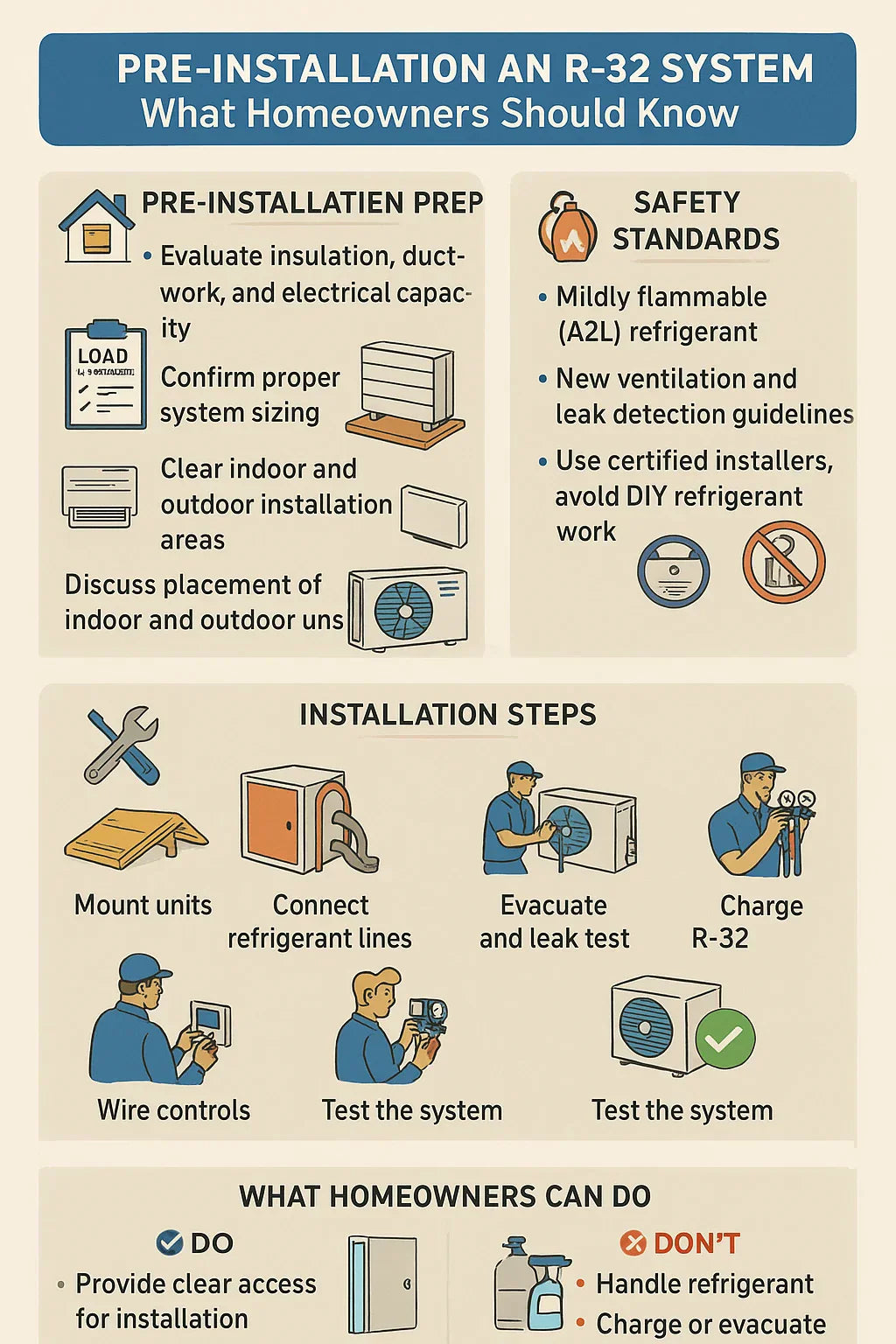

⚙️ 2️⃣ Pre-Installation Prep: What to Do Before Installation Day

R-32 systems are efficient and future-proof — but the key to their success starts before the first tool comes out. Here’s how to prepare your home and avoid delays.

🏡 Assess Your Home’s Readiness

-

Insulation check: Poor insulation will make even the most efficient system work harder.

-

Ductwork inspection: Leaks, dirt, or undersized ducts can reduce performance by 20–30%.

-

Electrical panel: R-32 systems need a dedicated 240V circuit — make sure your panel has room.

-

Condensate drain path: Plan where condensation will exit (especially in basements or attics).

🧮 Confirm Proper System Sizing

Don’t rely on “rules of thumb.” Ask your installer to perform a Manual J load calculation, which considers insulation, window area, climate zone, and occupancy.

This ensures your system is neither oversized nor undersized — both of which waste energy and shorten lifespan.

📘 Read: Energy.gov – Preparing for HVAC Installation

🧹 Prepare the Installation Space

-

Clear 3 feet around the outdoor condenser for airflow.

-

Provide indoor access for coil and line set installation.

-

Ensure attic or crawlspace lighting for installers if applicable.

-

Keep pets and kids away from the workspace.

Doing these steps before installation saves your crew time — and saves you labor costs.

🔧 3️⃣ What Makes R-32 Installation Different

R-32 systems aren’t radically different from R-410A systems — but there are key differences every homeowner (and contractor) should know.

| Feature | R-32 | R-410A |

|---|---|---|

| Refrigerant Type | Pure HFC | Blend (R-32 + R-125) |

| GWP (Global Warming Potential) | ~ 675 | ~ 2,088 |

| Flammability Rating | Mild (A2L) | Nonflammable (A1) |

| Refrigerant Charge | 20–30% less | Higher |

| Tools Required | A2L-rated hoses, recovery tanks | Standard |

| Servicing Simplicity | Easier (pure compound) | Moderate |

🔹 Why This Matters

-

R-32 has higher efficiency and lower environmental impact, but being mildly flammable, it’s handled under stricter A2L codes.

-

Installers must follow specific ventilation and leak-detection protocols.

-

Because it’s a single-component refrigerant, R-32 doesn’t separate (or “fractionate”) like blends do — so it’s easier to recover and recharge accurately.

📗 Reference: Daikin – Safe Use of R-32 Refrigerant

🧯 4️⃣ Safety Standards and Handling Practices

Let’s clear one thing up: R-32 is safe when installed correctly.

It’s rated A2L, meaning:

-

“A” = non-toxic

-

“2L” = low flammability and slow flame propagation

The risk only exists if refrigerant leaks into a confined, unventilated space and an ignition source is present — which is nearly impossible in a compliant installation.

🔹 Updated Code Requirements

Installers must:

-

Use A2L-rated hoses, manifolds, and recovery cylinders.

-

Avoid ignition sources (like open flames or switches) near refrigerant lines.

-

Provide proper ventilation during charging or recovery.

-

Install leak detectors in enclosed mechanical rooms (where required by code).

🔹 Homeowner Tip

Ask your contractor for their EPA 608 certification and A2L safety training. These are required credentials under federal law for refrigerant handling.

📘 Reference: ASHRAE – A2L Refrigerant Safety Standards

🧰 5️⃣ The Step-by-Step Installation Process

Here’s what the installation day looks like from my field experience. It usually takes one full day for a straightforward single-zone install and two days for larger systems.

Step 1: Mount the Indoor and Outdoor Units

-

Secure the air handler or indoor coil with adequate clearance for service.

-

Set the outdoor condenser on a level pad or wall bracket, away from direct sunlight and obstructions.

Step 2: Run and Connect Refrigerant Lines

-

Use copper tubing rated for A2L refrigerants.

-

Keep bends gentle and flare joints clean.

-

Avoid exceeding manufacturer’s line length limits (usually ≤ 50 ft total).

Step 3: Evacuation (Vacuum the System)

-

Remove moisture and air using a micron-rated vacuum pump.

-

Target ≤ 500 microns to ensure the system is dry.

Step 4: Pressure and Leak Test

-

Pressurize the system with dry nitrogen (≈ 300 psi) and hold for 15–30 minutes.

-

Any drop indicates a leak that must be repaired before charging.

📙 Guide: HVAC School – Proper Evacuation and Charging Procedures

Step 5: Charging the System with R-32

-

Charge by weight, per manufacturer label.

-

Use A2L-approved cylinders and electronic scales for accuracy.

-

No need to balance blend ratios — R-32 is pure.

Step 6: Electrical and Thermostat Wiring

-

Connect high-voltage (L1/L2) and control wiring.

-

Verify correct polarity, breaker sizing, and grounding.

-

Connect the thermostat or smart controller.

Step 7: Performance Testing

-

Run the system and verify:

-

Suction/discharge pressure within range

-

15–20 °F temperature split across coil

-

Steady compressor amperage draw

-

Proper fan rotation and airflow

-

Jake’s tip:

“Always verify superheat and subcooling — R-32 runs slightly higher pressure than R-410A, so precision matters.”

🏠 6️⃣ What Homeowners Can (and Can’t) Do Themselves

✅ DIY-Friendly Tasks

-

Clear installation space (indoor & outdoor).

-

Provide wall sleeves, drain piping, or mounting pads.

-

Paint or protect wall openings after install.

-

Replace filters and clean coils seasonally.

❌ Leave to Professionals

-

Refrigerant piping, evacuation, and charging.

-

Leak testing or pressure checks.

-

Electrical wiring and breaker connections.

-

Refrigerant recovery or disposal.

Handling refrigerants without certification can lead to EPA fines — and more importantly, it voids your equipment warranty.

Jake’s rule:

“Homeowners can prep and maintain, but never pressurize or charge. That’s the line between safe and sorry.”

🌬️ 7️⃣ Installation Site Planning Tips

R-32 systems depend heavily on good airflow and clearances. Placement mistakes can ruin efficiency.

📦 Outdoor Unit

-

Maintain 18–24 inches clearance on all sides and 60 inches above.

-

Avoid areas with heavy foot traffic or where snow drifts collect.

-

Mount on vibration pads to minimize noise transfer.

-

Face away from bedrooms and windows if possible.

🏠 Indoor Unit or Coil

-

Leave access space (≈ 12 inches) for coil cleaning and filter replacement.

-

Plan drain routing downhill to prevent clogs.

-

If in attic: install a secondary drain pan and float switch.

📏 Line Set and Layout

-

Keep refrigerant lines as short and straight as possible.

-

Follow manufacturer max limits (e.g., 50 ft total, 25 ft vertical).

-

Insulate suction lines with A2L-approved foam (UV resistant).

📘 Reference: LG HVAC – Installation Best Practices

🧠 8️⃣ Post-Installation Checklist for Homeowners

After your installer finishes, take 10 minutes to verify everything is in order:

| Task | Check |

|---|---|

| Unit runs quietly & smoothly | ✅ |

| Temperature difference between supply & return ≈ 15–20 °F | ✅ |

| Thermostat operates modes correctly | ✅ |

| Condensate drain flows freely | ✅ |

| Line set insulation intact | ✅ |

| Outdoor fan exhaust unobstructed | ✅ |

| Documentation (warranty + refrigerant label) provided | ✅ |

Jake’s pro tip:

Keep your AHRI certificate, invoice, and installer’s EPA 608 number together — you’ll need them for rebates and service claims.

⚠️ 9️⃣ Common Installation Mistakes to Avoid

Even experienced installers can trip up. Here’s what to watch for:

❌ Reusing Old Line Sets

Old oil or debris contaminates the R-32 charge. Always replace or flush with an A2L-compatible solvent.

❌ Skipping Nitrogen Purge While Brazing

This causes internal oxidation, creating flakes that clog expansion valves.

❌ Poor Vacuum

Residual moisture forms acid when combined with refrigerant oil, leading to compressor failure.

❌ Incorrect Refrigerant Weight

Overcharge or undercharge kills efficiency and stresses the compressor.

❌ Ignoring Duct or Airflow Sizing

Improper airflow can cut system efficiency by 25% and reduce SEER2 performance.

Jake’s advice:

“A perfect refrigerant charge means nothing if the airflow’s wrong. Ductwork is half the system.”

💵 🔟 Cost Factors & What to Expect

Installing an R-32 system isn’t much more expensive than R-410A — and it pays off through energy savings.

| Component | Average Range (USD) |

|---|---|

| Equipment (2.5–3 ton R-32 system) | $4,500 – $7,500 |

| Installation labor | $2,000 – $3,500 |

| Electrical & duct upgrades | $500 – $2,000 |

| Total Project | $6,500 – $10,000 |

🔸 Why It’s Worth It

-

Lower refrigerant volume (less cost over time).

-

10–15% higher efficiency than R-410A equivalents.

-

Eligible for rebates and tax credits under the Inflation Reduction Act.

📘 See: ENERGY STAR – HVAC Tax Credits

🧾 11️⃣ Maintenance After Installation

R-32 systems are easy to maintain, but routine care keeps them at peak efficiency.

🧽 Monthly / Quarterly

-

Check filters (replace or clean).

-

Inspect condensate drain for clogs.

-

Rinse outdoor coil gently with a hose.

🛠️ Yearly

-

Professional refrigerant charge check.

-

Coil cleaning (evaporator + condenser).

-

Verify electrical connections and sensors.

-

Test safety controls and leak detectors.

Jake’s seasonal advice:

“Book your tune-up before the cooling season hits. That’s when techs are fresh, and you won’t be waiting in a 95-degree emergency line.”

💬 12️⃣ Homeowner FAQ

❓ Can I Convert My Old R-410A System to R-32?

No — compressors, oils, and components differ. Retrofitting is unsafe and non-compliant. Always install a purpose-built R-32 unit.

❓ Is R-32 Flammable Inside My Home?

It’s mildly flammable, but systems use very small refrigerant quantities (less than a BBQ propane tank) and sealed circuits. Risk is near zero in a code-compliant install.

❓ How Long Will an R-32 System Last?

With proper maintenance, 15–20 years — often longer thanks to lower compressor strain.

❓ Will My Electric Bill Go Down?

Typically 10–20% lower compared to an older R-410A or R-22 unit of the same size.

✅ 13️⃣ Final Take: R-32 Installation Is a Smart, Safe Upgrade When Done Right

R-32 systems mark a huge leap in HVAC evolution. They’re efficient, environmentally friendly, and engineered for modern homes — but installation quality makes all the difference.

When done right, you’ll enjoy:

-

Lower energy bills

-

Quieter operation

-

Long-term reliability

-

Compliance with 2025 EPA standards

If you take one thing from this article, remember this:

“R-32 isn’t harder to install — it just demands precision. Find a contractor who treats it that way, and you’ll have comfort that’s cleaner, cheaper, and built for the future.” — Jake Lawson

In the next topic we will know more about: How to Maintain Your R-32 System for Long-Term Performance