1. 🏠 Why Cost Transparency Matters

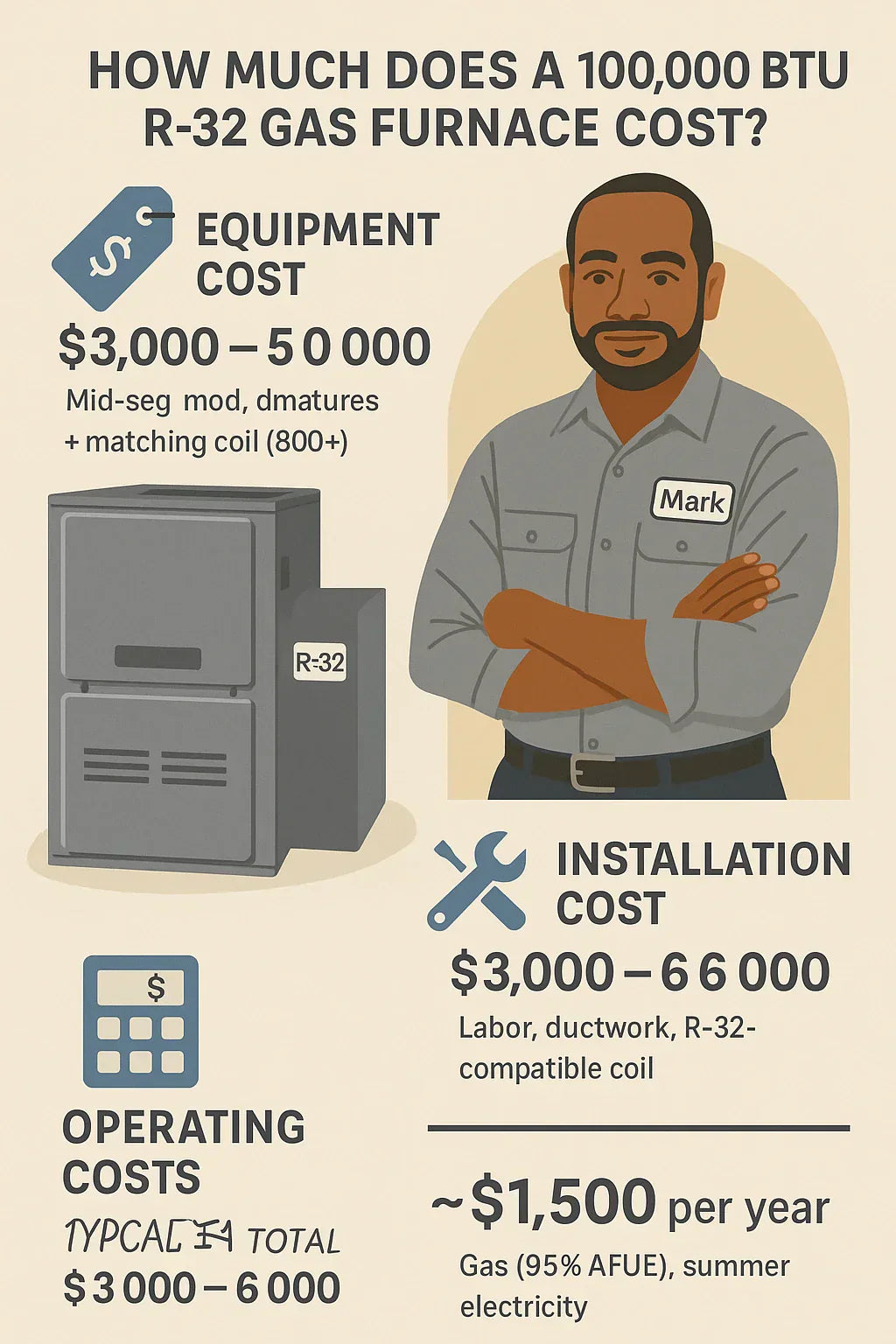

When Mark started shopping for a 100,000 BTU gas furnace, he quickly realized that the number on the price tag wasn’t the whole story.

Between equipment selection, installation labor, permits, and long-term operating costs, the real investment in a new heating system can vary by thousands of dollars.

And with the shift to R-32-compatible systems in 2025, pricing dynamics are changing—both for new units and for long-term maintenance.

Mark’s takeaway:

“If you only budget for the furnace itself, you’re going to be blindsided later. You’ve got to know the whole cost picture.”

2. 📦 Equipment Costs – Your Upfront Purchase

The first number most homeowners see is the unit cost of the furnace. For a 100,000 BTU R-32-compatible gas furnace, prices depend on efficiency rating, features, and brand.

| Furnace Type | AFUE Rating | Typical Price Range (Unit Only) |

|---|---|---|

| Standard Efficiency (80–83%) | Mid-efficiency | $1,500 – $2,500 |

| High Efficiency (90–98%) | Condensing furnace | $2,500 – $4,500 |

| Premium Feature Models | Two-stage or modulating burners, ECM blower | $3,500 – $5,500 |

R-32 Compatibility Note:

Even though furnaces themselves don’t use refrigerant, an R-32-compatible furnace is paired with coils and AC/heat pump systems designed for R-32. This adds to cost because:

-

You may need a new matching evaporator coil.

-

Line set upgrades may be required (Goodman R-32 Facts PDF).

3. 🛠 Installation Costs – The Professional Setup Factor

The biggest variable in your total budget is installation labor. Mark learned that installation costs are regionally dependent, but also driven by:

-

The complexity of venting.

-

Whether ductwork is reused or replaced.

-

The need for refrigerant line upgrades.

3.1 Typical Labor Ranges (Unit Replacement)

| Installation Type | Typical Cost |

|---|---|

| Basic Replacement (reuse ducts & venting) | $1,200 – $2,000 |

| Moderate Upgrade (minor duct/vent changes) | $2,000 – $3,500 |

| Full Replacement (ductwork, venting, coil upgrade) | $3,500 – $6,000 |

R-32 Factor:

If you’re switching from R-410A to R-32, you’ll likely need:

-

New refrigerant lines to meet A2L refrigerant safety standards

-

A coil rated for R-32 operating pressures.

4. 📜 Permits, Codes & Inspection Fees

Mark’s contractor reminded him that HVAC permits aren’t optional—local codes require them for safety and compliance.

Typical Costs:

-

$50 – $500 depending on city/county.

-

Higher in areas with multiple inspections (rough-in + final).

For R-32 installs, inspectors may specifically check:

-

Proper refrigerant labeling.

-

Ventilation and leak detection compliance for A2L refrigerants (AHRI Low-GWP Guidance).

5. 📅 Ongoing Operating Costs

Mark didn’t stop at purchase—he wanted to know what it costs to run a 100,000 BTU furnace.

5.1 Gas Consumption Estimate

-

At 95% AFUE, a 100,000 BTU furnace delivers 95,000 BTU/hr output.

-

In a cold-climate winter (~1,000 heating hours/year), that’s:

-

At $1.50/therm (U.S. avg. Jan 2025), annual gas cost ≈ $1,500 (U.S. EIA Natural Gas Prices).

5.2 Summer Electric Costs (Cooling)

-

Paired with R-32 AC/heat pump, summer cooling bills may be 5–10% lower than with R-410A, thanks to higher refrigerant efficiency (Daikin R-32 Energy Study).

6. 🛡️ Warranty & Protection Plan Costs

Mark’s advice: Don’t skip the warranty math.

-

Manufacturer warranties: 10 years parts, limited heat exchanger lifetime.

-

Labor warranties: Often only 1 year unless you purchase extended coverage.

-

Extended service plans: $150 – $400/year, or $1,000+ for multi-year coverage.

High-efficiency R-32 systems may have separate warranties for the refrigerant components—check fine print.

7. 📉 How R-32 Can Reduce Long-Term Costs

Mark identified three ways R-32 systems could save money over 10–15 years:

-

Lower Summer Energy Bills – Better heat transfer = shorter cooling cycles.

-

Cheaper Recharge Costs – R-32 is a single-component refrigerant, making servicing simpler and reducing waste

-

Avoiding R-410A Price Inflation – As R-410A phases out, servicing costs will rise (ACHR News Refrigerant Phaseout).

8. 💳 Financing & Incentives

Federal Tax Credit:

High-efficiency furnaces (≥97% AFUE) can qualify for $600 federal tax credit under the Inflation Reduction Act (EnergyStar.gov IRA Incentives).

Local Rebates:

Many utilities offer $200–$1,200 rebates for upgrading to high-efficiency systems.

Financing:

HVAC dealers often offer:

-

0% interest for 12–18 months.

-

Long-term plans (5–10 years) at 4–8% APR.

9. 📊 Mark’s Real-World Budget Example

For Mark’s 2,000 sq ft home in a cold Midwestern climate:

| Item | Standard Efficiency | High Efficiency (R-32 Compatible) |

|---|---|---|

| Furnace Unit | $1,800 | $3,200 |

| Matching Coil | $0 (reuse) | $800 |

| Installation Labor | $2,200 | $3,500 |

| Permits/Inspection | $250 | $300 |

| Total Upfront | $4,250 | $7,800 |

| Annual Operating (Gas + Electric) | $1,750 | $1,500 |

| 10-Year Op. Cost | $17,500 | $15,000 |

| 10-Year Total | $21,750 | $22,800 |

Note: The high-efficiency R-32 system cost slightly more over 10 years but provided better comfort, lower emissions, and higher resale value.

Mark’s Closing Advice:

“Don’t just hunt for the cheapest furnace. Price out the whole system, installation, and what it’ll cost to run for a decade. And if you’re going R-32, make sure your contractor is trained for A2L refrigerants—you’ll get better performance and safer installs.”

In the next topic we will read more about: Installation Guide: What to Know Before You Replace Your Gas Furnace