A 10-ton packaged rooftop air conditioner (RTU) is no small investment. With equipment and installation running between $20,000 and $30,000, businesses naturally want to know:

👉 How long will it last?

👉 When should we start planning for replacement?

👉 What’s the smartest way to maximize ROI over its life?

The truth is: commercial packaged ACs don’t last forever. But with the right brand, maintenance, and planning, you can extend their life, minimize downtime, and even turn replacement into an opportunity for energy savings and tax benefits.

This guide breaks down everything you need to know about the lifespan of a 10-ton packaged AC and how to strategically plan for replacement.

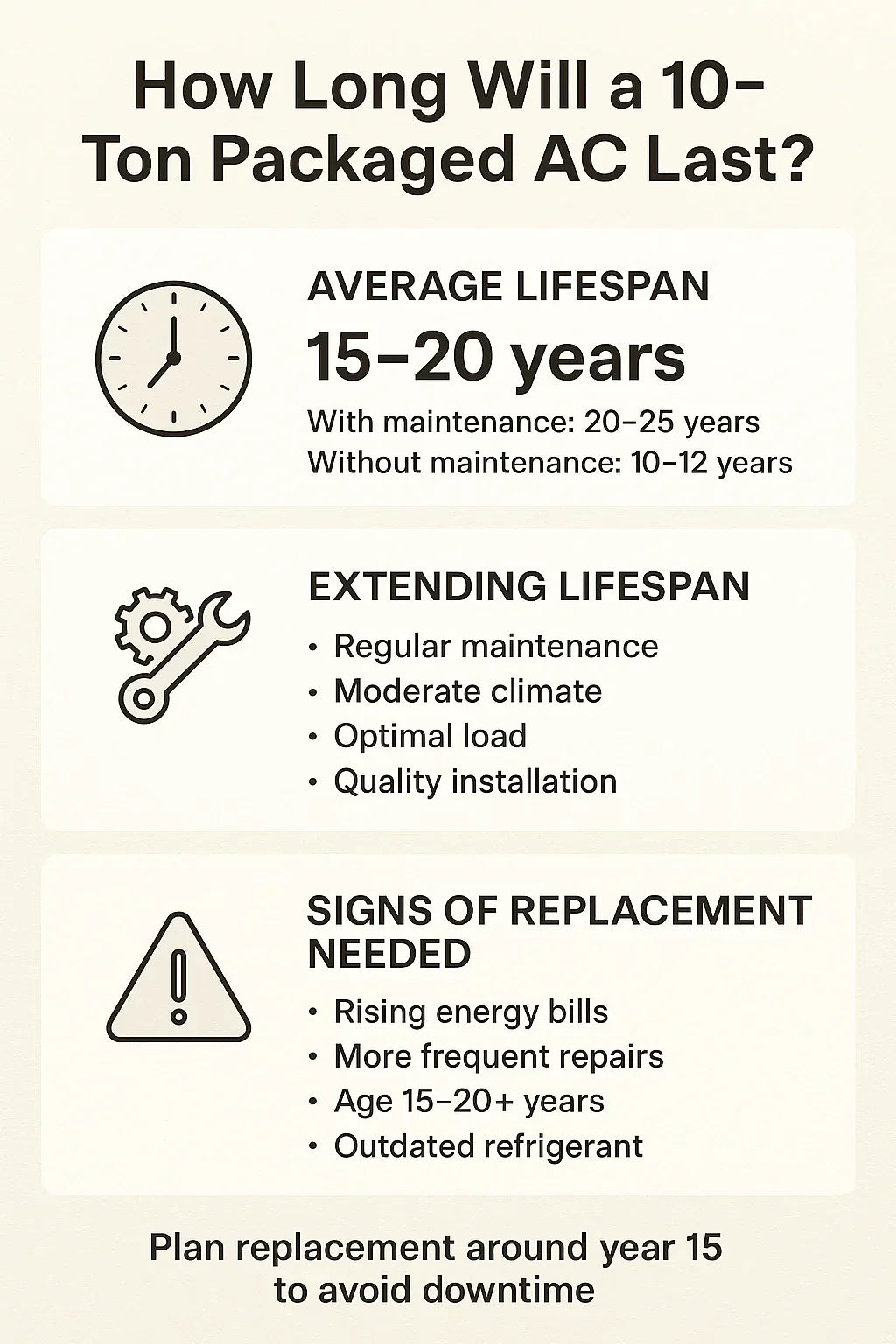

📊 1. Average Lifespan of a 10-Ton Packaged AC

Industry studies (including ASHRAE equipment life expectancy tables) show:

-

Standard lifespan: 15–20 years

-

Well-maintained systems: up to 25 years

-

Poorly maintained or overworked units: 10–12 years

Why the range?

Commercial HVAC systems live in tough environments. Rooftop placement exposes them to:

-

UV radiation

-

Freezing winters

-

Dust, grease, and debris

-

Salt air (in coastal regions)

These factors cause wear over time. But with the right upkeep, many businesses get 2 decades or more from a 10-ton packaged unit.

📖 Reference: ASHRAE – Equipment Life Expectancy Tables

⚙️ 2. Factors That Impact Lifespan

Not all systems age equally. Here are the main factors:

🛠️ Maintenance Quality

-

Dirty coils force compressors to overwork.

-

Clogged filters strain airflow.

-

Neglect = shortened life by 5+ years.

🏭 Operating Load

-

Units running 24/7 at max capacity wear out faster.

-

Oversized units → short cycling, more stress on components.

🌦️ Climate Conditions

-

Hot climates = higher runtime hours.

-

Cold climates = more freeze/thaw stress.

-

Coastal environments = faster corrosion.

🏗️ Installation Quality

-

Poor duct design = restricted airflow, reduced lifespan.

-

Incorrect sizing = unnecessary cycling and wear.

🏆 Brand + Model Quality

-

Premium manufacturers (Daikin, Trane, Carrier) use higher-grade materials and components.

-

Lower-cost imports may fail 5–7 years sooner.

🏆 3. Daikin’s 10-Ton Systems: Built for Longevity

Daikin is known worldwide for durability and engineering quality. Their 10-ton packaged RTUs often outperform industry averages.

Design Advantages

-

Powder-coated cabinets resist rust and UV damage.

-

Variable-speed compressors reduce on/off cycles, cutting stress.

-

Smart diagnostics catch issues before they cause breakdowns.

-

Heavy-duty coils and fans withstand years of rooftop exposure.

Real-World Longevity

-

Many Daikin 10-ton packaged units deliver 20–25 years of reliable service.

-

Businesses that follow preventive maintenance schedules often delay replacement costs by 5+ years compared to competitors.

📖 Reference: Daikin Applied – Rooftop Packaged Units

🛠️ 4. Maintenance for Maximum Lifespan

Maintenance isn’t a cost—it’s an investment in lifespan and efficiency.

Essential Maintenance Schedule

-

Quarterly: Change filters, inspect belts.

-

Semi-annual: Clean coils, check refrigerant levels, lubricate bearings.

-

Annual: Full system tune-up, control calibration, vibration analysis.

Cost vs. Benefit

-

Average annual maintenance: $2,000–$3,000.

-

Average savings: $15,000–$20,000 in avoided early replacements and efficiency losses.

-

ROI: Maintenance costs pay for themselves multiple times over.

📖 Reference: EPA – Preventive Maintenance Programs

🚨 5. Signs It’s Time for Replacement

Even the best-maintained systems eventually reach end-of-life. Watch for these signs:

-

Frequent Repairs

-

More than $3,000/year in repair bills = red flag.

-

-

Rising Utility Costs

-

Energy use creeping up despite tune-ups? Efficiency decline.

-

-

Poor Comfort Control

-

Inconsistent temps, humidity issues, or excessive noise.

-

-

Refrigerant Issues

-

Older units may rely on phased-out refrigerants like R-22.

-

-

Age

-

If your system is 15–20+ years old, replacement planning should begin.

-

📈 6. Replacement Planning: Repair vs. Replace

Business owners often struggle with this decision. A simple rule:

👉 If repairs exceed 50% of replacement cost, replacement is usually smarter.

Example:

-

Replacement cost for a Daikin 10-ton RTU = $25,000.

-

Accumulated repairs over 2 years = $14,000.

-

Smart choice: Replace before sinking more money.

ROI of Proactive Replacement

-

New 15 IEER2 Daikin saves $3,000–$5,000/year in energy.

-

Utility rebates + tax incentives can cut upfront cost by $5,000–$10,000.

-

Payback period: 5–7 years.

-

After payback → pure savings + better comfort.

📖 Reference: DSIRE – Energy Incentives Database

💡 7. Lifecycle Cost Example (20 Years)

Let’s compare two businesses:

Business A – No Replacement Planning

-

Keeps old 12 IEER unit running for 20 years.

-

Higher repairs ($4,000/year in later years).

-

Higher energy bills ($3,000/year more vs. modern system).

-

20-year total cost = $280,000.

Business B – Smart Replacement at Year 15

-

Replaces unit with Daikin 15 IEER2.

-

Enjoys lower energy bills + rebates.

-

20-year total cost = $240,000.

👉 Business B saves $40,000 over 20 years by planning strategically.

🏆 Key Takeaways

-

Average lifespan: 15–20 years; Daikin units can last 25 years with care.

-

Factors: maintenance, climate, load, installation quality, and brand.

-

Start replacement planning around year 15 to avoid costly downtime.

-

Smart planning can save tens of thousands in repairs + energy costs.

-

Daikin’s 10-ton packaged systems offer industry-leading longevity, efficiency, and ROI.

👉 The question isn’t just “How long will it last?”—it’s “When is the smartest time to reinvest for maximum ROI?”

In the next topic we will know more about: Is a 10-Ton Packaged AC the Right Size for Your Commercial Space?