When you’re pricing out a new furnace, most people focus on the brand, efficiency rating, and BTU size. But here’s a big factor that can make or break your budget: your home’s layout.

Two houses with the same furnace model can have installation costs that differ by thousands — all because of how the home is designed. Long duct runs, cramped furnace closets, and multi-story floor plans can all mean more labor, more materials, and sometimes even more equipment.

In this guide, we’ll break down the main layout-related factors that impact furnace installation costs, plus what you can do to keep those costs under control.

📘 If you’re looking for overall cost ranges and brand comparisons, start with How Much Does a New Furnace Cost?.

Why Layout Matters in Furnace Installation Pricing

Furnace installation isn’t just a matter of “plug and play.” Contractors have to work with the physical reality of your home, and that can significantly change how much time and effort the job takes.

Here’s why your home’s layout affects the bottom line:

-

Labor time – Tight spaces or hard-to-reach areas take longer to work in.

-

Material usage – More ductwork, venting, and fittings cost more.

-

Equipment choice – Certain layouts limit the size or style of furnace that can be installed.

As the U.S. Department of Energy’s Home Heating Systems guide explains, furnace efficiency and performance rely heavily on proper duct design and installation — and that starts with the space it’s going into.

Common Layout Factors That Increase Costs

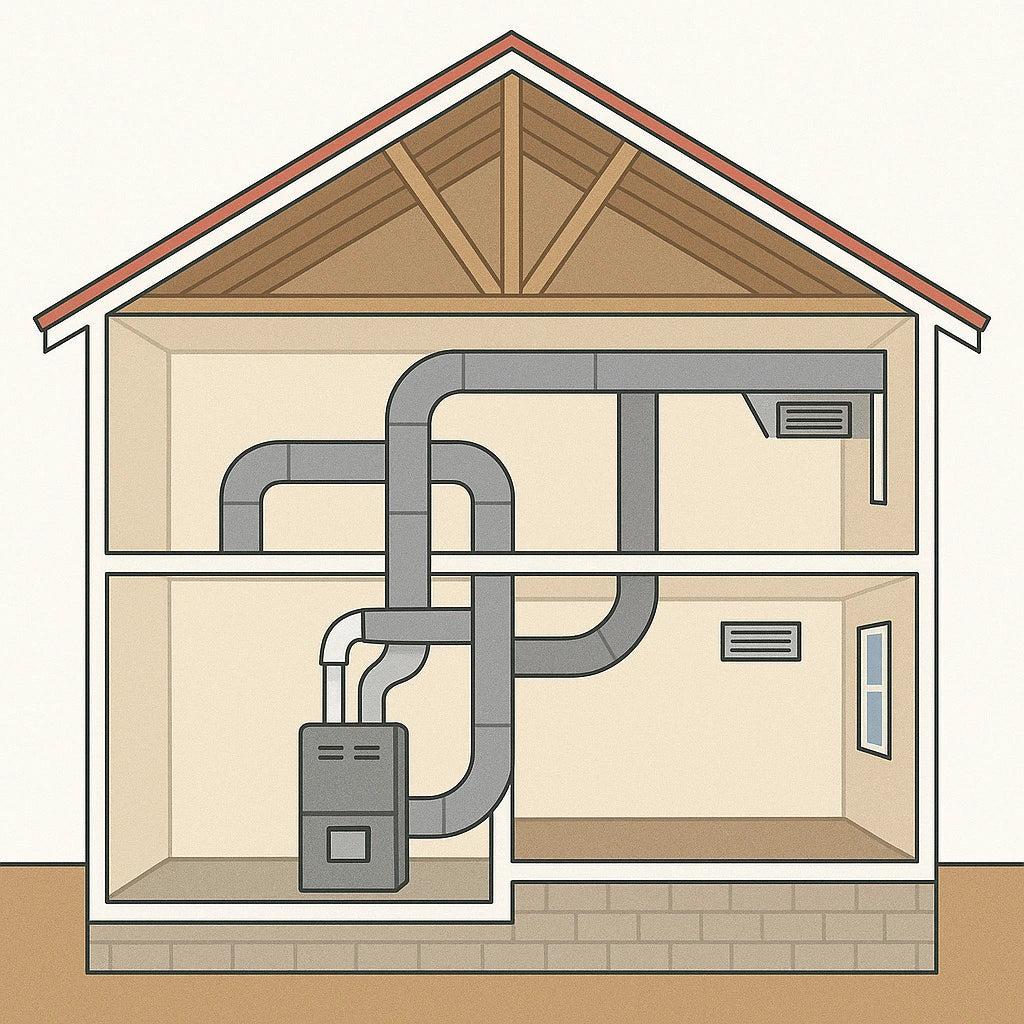

1. Multiple Levels and Long Duct Runs

If your home has multiple stories or the furnace is located far from the main living areas, installers will need to run more ductwork. This not only increases material costs but also labor time, especially if ducts have to be routed through tight joists or around structural obstacles.

2. Tight or Inaccessible Furnace Locations

Placing a furnace in a cramped crawlspace, attic, or small utility closet can increase costs. Technicians may need special equipment to move the unit in and out, and working in confined spaces slows installation.

The Better Business Bureau’s tips for hiring a contractor recommend asking installers whether your furnace location will require extra labor so you can prepare for potential added costs.

3. Existing Ductwork Design

Older homes often have ductwork that isn’t sized correctly for today’s high-efficiency furnaces. If your ducts are undersized, leaky, or damaged, they may need to be replaced or modified, which adds to the total bill.

4. Chimney and Venting Constraints

For gas and oil furnaces, venting requirements depend on the fuel type and efficiency rating. If your home’s existing chimney or vent path can’t be used, new venting must be installed. This can mean cutting through walls, ceilings, or roofs — all labor-intensive work.

The Role of Furnace Size and Type in Different Layouts

Your home’s design also influences the kind of furnace that’s best for you.

-

Split-level homes – Often need zoned systems or variable-speed blowers to keep temperatures balanced between levels.

-

Ranch homes – Usually have long trunk lines, which require strong blowers to maintain airflow.

-

Multi-story homes – May require multiple return air ducts for even heating.

The ENERGY STAR HVAC sizing guidance emphasizes matching furnace capacity and airflow to the layout to prevent comfort issues and energy waste.

Accessibility and Building Code Compliance

Furnaces need adequate clearance for safe operation and maintenance. If your home’s layout doesn’t meet these standards, the installer may need to move or reconfigure the furnace location.

The ANSI 2024 International Residential Code overview outlines updated space and venting requirements that contractors must follow. These rules can sometimes mean extra framing, platform construction, or vent relocation.

How Layout Affects Labor Time and Permits

Labor is one of the largest cost components of furnace installation, and layout has a direct impact on it:

-

Straightforward installs – Basement with clear duct access can be done in a day.

-

Complex installs – Multiple levels, hard-to-access ductwork, or relocation of equipment can take 2–3 days.

Local permits may also cost more if structural work or major duct rerouting is required.

Ways to Minimize Layout-Related Installation Costs

The good news? There are ways to plan ahead and reduce the impact of layout challenges on your installation bill.

1. Plan Duct Routes During Renovations

If you’re remodeling, coordinate with your HVAC contractor to optimize duct paths before walls are closed.

2. Choose Equipment That Fits Your Space

Compact furnaces and multi-position air handlers can make tight installations easier and faster.

3. Schedule a Site Visit Before Signing

Have each contractor walk your home to identify potential access issues and include them in their written quote.

Case Study – Two Similar Homes, Different Layouts, Different Costs

-

Home A: Single-story ranch with furnace in basement, short duct runs, easy venting – installation cost: $6,800.

-

Home B: Two-story home with furnace in attic, long duct runs to first floor, additional venting – installation cost: $8,900.

Same brand, same BTU size, but $2,100 difference due purely to layout.

Final Thoughts – Plan Ahead for a Smoother Install

Your home’s layout plays a bigger role in furnace installation cost than most homeowners realize. Tight spaces, multi-story duct runs, and code compliance can all add to labor and material expenses.

By planning ahead, choosing the right equipment, and getting detailed bids, you can avoid surprises on installation day — and make sure your system is set up for maximum comfort and efficiency.

📘 Next read: Off-Season Furnace Deals: When to Buy for the Best Price for tips on timing your installation for the best discounts.

Alex Lane

Your Home Comfort Advocate