Installing an air conditioner isn’t just about connecting wires and tightening bolts. It’s about doing it the right way — with care, precision, and respect for the system that’s going to cool your home for the next 15 years.

Tony’s been installing HVAC systems for over two decades, and if there’s one thing he’s learned, it’s this:

“Half the battle of efficiency is won during installation.”

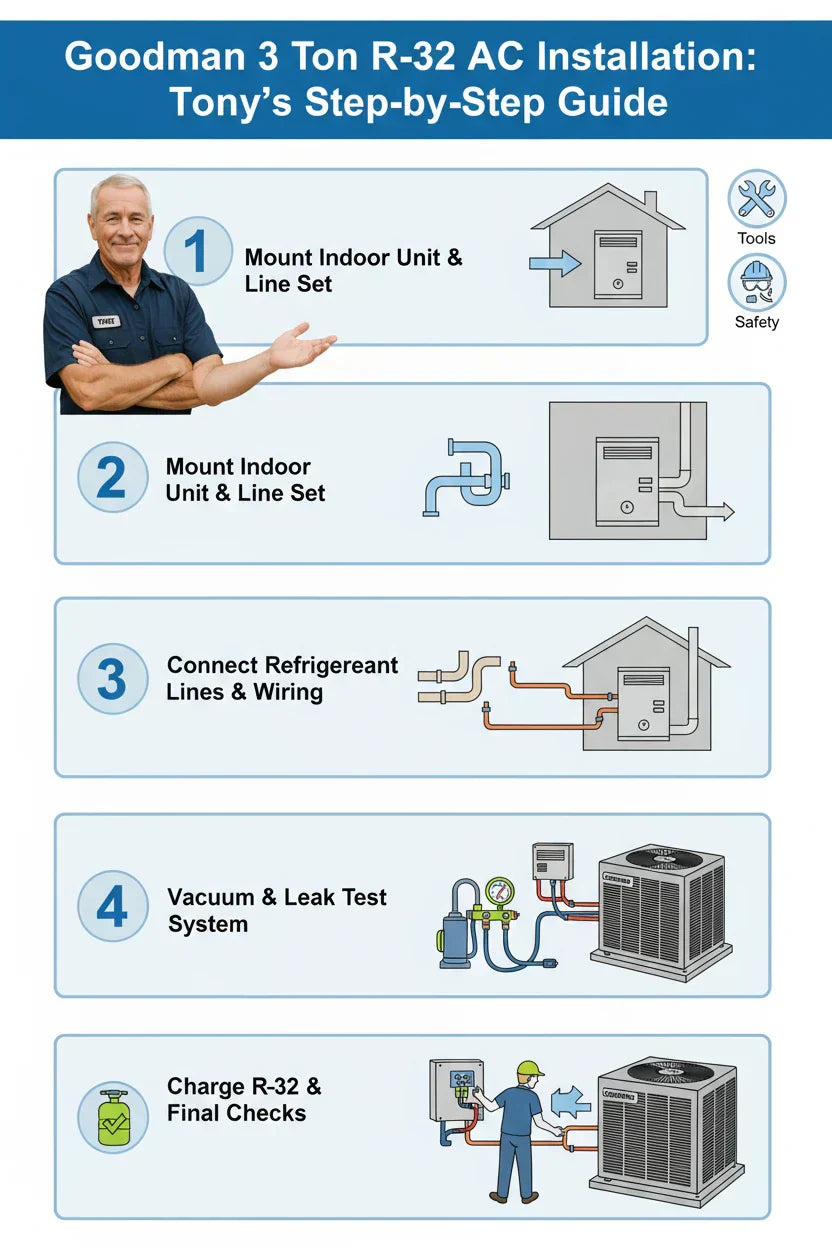

In this complete guide, Tony walks you through the entire process of installing a Goodman 3 Ton 14.4 SEER2 R-32 Air Conditioner Condenser (Model GLXS4BA3610) — step-by-step, just like he would on the job site.

Whether you’re a homeowner who wants to understand the process or a DIY enthusiast prepping your space for a professional install, this guide is for you.

🏁 Why Proper Installation Matters

You can buy the most efficient unit on the market, but if it’s not installed right, you’ll never see those efficiency numbers on your utility bill.

A misleveled pad, loose connection, or improper vacuum can cost you hundreds of dollars a year in lost performance.

Tony’s rule of thumb:

“You only install once — do it right, and you’ll never touch it again.”

The Goodman 3 Ton R-32 condenser is designed for smooth, energy-efficient cooling, but it’s only as good as the installation behind it. Let’s dive in.

🧊 Step 1: Pre-Installation Planning & Safety

✅ Verify Your System Components

Before you even grab a wrench, confirm you’ve got the right setup:

-

Condenser: Goodman GLXS4BA3610 (R-32, 14.4 SEER2)

-

Air Handler: Goodman R-32 compatible unit (vertical or horizontal)

-

Line Set: Rated for R-32 (½ in liquid line, ¾ in suction line)

-

Thermostat: 24V programmable, matched to system specs

Tony’s tip: “Mismatched components kill efficiency faster than bad insulation.”

🧰 Tools & Equipment Checklist

You’ll need:

-

Level and measuring tape

-

Vacuum pump and micron gauge

-

Torque wrench and manifold gauge set (R-32 compatible)

-

Nitrogen tank + regulator

-

Digital multimeter

-

Pipe bender, flaring tool, brazing torch

-

PPE: gloves, safety glasses, long sleeves

⚠️ Safety First

-

Disconnect power at the main breaker.

-

Verify no voltage with a multimeter before touching wires.

-

Work in a ventilated area when brazing or testing refrigerant lines.

-

Always wear gloves and eye protection.

For more on electrical safety, check out OSHA’s Electrical Safety Guidelines.

📏 Step 2: Preparing the Installation Site

A level, well-ventilated space is essential for your condenser.

🪵 Setting the Condenser Pad

-

Choose a shaded spot on the north or east side of your home if possible.

-

Pour or place a concrete or composite pad at least 3 inches thick.

-

Ensure the pad is perfectly level using a bubble level — uneven footing stresses the compressor.

-

Add rubber isolation pads under the unit feet to reduce vibration noise.

Tony’s reminder:

“That pad’s your foundation — if it wobbles, your system will hum like a truck.”

🌬️ Clearance and Ventilation

Maintain:

-

24 inches of clearance on all sides

-

60 inches of vertical clearance above the unit

-

At least 12 inches away from gutters, vents, or downspouts

Learn more installation spacing best practices at Energy.gov’s Central AC Guide.

🔌 Step 3: Electrical Setup and Wiring

Always start with the power off. Electricity and refrigerant are not forgiving.

🔧 Install the Disconnect Box

-

Mount within 4 feet of the condenser and visible from the unit.

-

Use weatherproof conduit and fittings.

-

Route wires through flexible conduit for strain relief.

⚡ Wire the System

Follow Goodman’s wiring diagram (usually located inside the condenser panel):

-

Connect the 240V supply wires to the disconnect switch.

-

Run L1 and L2 from the disconnect to the contactor terminals inside the condenser.

-

Connect ground wire securely to the grounding lug.

-

Route low-voltage thermostat wires through separate conduit to prevent interference.

Tony’s pro tip:

“Double-check polarity before energizing. A reversed wire can fry a $500 control board in seconds.”

Reference: NEC Code Article 440 – HVAC Equipment Wiring Standards.

🧮 Step 4: Installing the R-32 Line Set

The line set is the artery of your AC — it carries refrigerant between your indoor and outdoor units.

📏 Sizing and Routing

-

Use ½-inch liquid and ¾-inch suction lines rated for R-32 pressures.

-

Keep runs under 50 feet whenever possible.

-

Avoid sharp bends — gentle curves maintain refrigerant flow.

-

Insulate the suction line fully with ¾-inch Armaflex or equivalent.

🔥 Brazing the Connections

-

Purge with dry nitrogen while brazing to prevent oxidation.

-

Use 15% silver brazing rods for strong, leak-free joints.

-

Cool the joint with a wet rag before applying insulation.

Tony’s golden rule:

“If you don’t purge with nitrogen, you’re leaving burnt junk inside your copper — and that junk clogs TXVs.”

Learn proper purging and brazing from HVAC School’s Nitrogen Purging Guide.

💨 Step 5: Pressure Testing the Lines

Before pulling a vacuum, ensure the line set and brazed joints can hold pressure.

-

Connect nitrogen tank to service port.

-

Pressurize the system to 350 psi and close the valve.

-

Watch your gauges for 30 minutes.

-

No drop = no leak.

If pressure falls, recheck all brazed connections with soapy water or an electronic leak detector.

“If it won’t hold nitrogen, it won’t hold refrigerant,” Tony reminds.

🧯 Step 6: Evacuation & Vacuum Testing

This is the most crucial — and often skipped — step. Evacuation removes moisture and non-condensable gases that ruin efficiency and oil lubrication.

Step-by-Step Vacuum Procedure

-

Connect vacuum pump and micron gauge to both high and low ports using core removal tools.

-

Run the pump until the gauge reads ≤ 500 microns.

-

Close valves and monitor for 15 minutes — pressure should stay steady.

-

If microns rise quickly, find the leak before proceeding.

Tony’s mantra:

“Moisture is the silent killer of compressors. Pull a deep vacuum and don’t rush it.”

🔓 Step 7: Releasing R-32 Refrigerant

Once the system passes vacuum, it’s ready to be charged.

Goodman ships R-32 condensers pre-charged for a 15-foot line set. If your lines are longer or shorter, adjust per the manual.

Charging Steps

-

With service valves closed, slowly open the liquid line valve halfway for 15 seconds.

-

Then fully open both liquid and suction valves using a hex key.

-

Listen for the refrigerant flow — it should be smooth, not hissing violently.

-

Use a leak detector to check every joint and fitting.

For EPA compliance and handling best practices, see EPA Section 608 Refrigerant Rules.

⚙️ Step 8: Electrical Testing & System Startup

✅ Pre-Power Checklist

-

Confirm disconnect is wired and grounded properly.

-

Thermostat set to Cool.

-

All access panels secured.

⚡ Power Up

-

Flip the breaker and power up the system.

-

Wait 5 minutes to let the compressor’s internal crankcase heater warm up.

-

Start cooling mode and observe operation.

Measure key parameters:

-

Line voltage: 208–230V

-

Compressor amp draw: should match or stay below nameplate rating

-

Outdoor fan operation: smooth, no vibration

Tony’s advice:

“Always test under a stable load. Don’t charge or diagnose while pressures are still equalizing.”

Reference Goodman’s technical literature and installation manuals.

🌬️ Step 9: Fine-Tuning the System

📏 Check Airflow

-

Measure temperature difference (ΔT) between supply and return:

-

Ideal range: 16–22°F

-

-

Adjust blower speed taps on air handler if needed.

🌡️ Check Pressures

-

Suction pressure (at 75°F ambient): ~120–140 psi for R-32

-

Liquid pressure: ~350 psi depending on temperature

🌡️ Check Superheat and Subcooling

-

Superheat (TXV systems): 8–12°F

-

Subcooling: 8–10°F

Tony’s rule:

“Don’t chase pressure numbers. Temperature tells you the truth.”

🧾 Step 10: Final Inspection & Documentation

A professional installation ends with documentation — not duct tape.

-

Record:

-

Suction & liquid pressures

-

Superheat/subcooling readings

-

Final charge weight (if adjusted)

-

Line length and vertical rise

-

Micron reading and test results

-

-

Label the disconnect box with circuit info and date of install.

-

Take photos of serial numbers for warranty registration.

🧽 Step 11: Maintenance & Homeowner Education

Once installed, the system needs only basic seasonal care:

Every 1–3 Months

-

Replace or clean return filters.

-

Keep indoor vents unblocked.

Every 6 Months

-

Rinse condenser coils with low-pressure water.

-

Clear debris and leaves from around the unit.

Annually

-

Have a licensed HVAC tech check refrigerant pressures and electrical connections.

-

Confirm no corrosion on service valves or contactors.

For more maintenance tips, see Energy.gov’s AC Maintenance Guide.

Tony says:

“Treat your system like your truck — regular oil changes keep it running smooth. Clean coils do the same for your AC.”

💬 Step 12: Tony’s FAQ — Homeowners Ask

Q1: Can I install the Goodman 3 Ton R-32 myself?

“You can handle site prep, pad placement, and wiring conduit. But refrigerant handling and system charging must be done by a licensed pro under EPA rules.”

Q2: Is R-32 dangerous to work with?

“It’s mildly flammable (A2L), but sealed and safe in use. Just don’t braze with refrigerant inside.”

Q3: How long will the installation take?

“A professional crew can install and test a Goodman R-32 system in 5–7 hours if prep is done right.”

Q4: How often should I check refrigerant levels?

“Once a year during maintenance. If the system is tight, it shouldn’t lose charge at all.”

🧩 Step 13: Tony’s Final Advice

“Installing an AC isn’t about speed — it’s about precision. Every joint you braze and every wire you tighten decides how long that system will last.”

Tony’s closing checklist:

✅ Level pad

✅ Tight nitrogen-tested joints

✅ Deep vacuum (≤ 500 microns)

✅ Proper electrical polarity

✅ Clean airflow path

If all five boxes are checked, your Goodman 3 Ton R-32 system is set for years of reliable, efficient cooling.

In the next topic we will know more about: How Much Does a 3 Ton R-32 AC System Cost? Real-World Budgeting & Value Insights