🔥 1. Introduction – Why Your Heating Choice Matters

When buying a commercial packaged AC & heating unit, you’ve got two big heating options:

-

Gas furnace heat (natural gas or propane)

-

Electric resistance heat

Both fit in the same rooftop or ground-mounted cabinet alongside your AC components, but the heating method you choose will dramatically affect:

-

Upfront price

-

Operating costs

-

Performance in different climates

-

Maintenance requirements

-

Overall lifespan and ROI

The tricky part? The “better” choice depends on where your building is, how you use it, and your local energy rates.

I’ve installed and overseen both in warehouses, offices, and retail spaces—and I can tell you: pick wrong, and you’ll pay for it every month.

Best 6-10 Ton Commercial Packaged Air Conditioner and Gas Furnace Units

🏭 2. How Gas Furnace Heat Works in a Packaged Unit

A gas furnace packaged unit works just like a standalone commercial gas furnace, except it shares the same cabinet as the AC.

How it works:

-

Natural gas or propane enters the burner assembly.

-

An electronic ignition lights the burners.

-

Heat from combustion warms the heat exchanger.

-

Air passes over the heat exchanger, picking up warmth.

-

The blower moves that heated air through your duct system.

Efficiency Ratings:

Commercial gas furnaces are rated by AFUE (Annual Fuel Utilization Efficiency). In 2025, most packaged gas units hit 80–95% AFUE.

Pros:

-

Lower operating cost in cold climates (gas heat often costs less per BTU than electric).

-

Better heating capacity—warms up large spaces faster.

-

Reliable in sub-freezing temps—no performance drop-off like heat pumps.

-

Long lifespan with proper maintenance.

Cons:

-

Higher upfront cost than electric models.

-

Requires gas line installation or upgrade.

-

Regular inspections needed for safety (heat exchanger cracks, venting, etc.).

-

Fuel price volatility in some markets.

⚡ 3. How Electric Heat Works in a Packaged Unit

Electric resistance heating uses coils inside the air handler to generate heat when current flows through them.

How it works:

-

Electricity passes through resistance wires or coils.

-

The coils heat up, much like a toaster element.

-

The blower moves air over these coils into the ducts.

-

The process continues until the thermostat is satisfied.

Pros:

-

Lower purchase price for the unit.

-

Easier installation—no gas lines or venting.

-

No combustion, so no flue gas or carbon monoxide risk.

-

Minimal maintenance—just coil inspections and electrical checks.

Cons:

-

Higher operating cost in most regions (electricity per BTU is usually pricier than gas).

-

Less efficient for large spaces or very cold climates.

-

Heating output tied to available electrical service—may need costly panel upgrades for larger units.

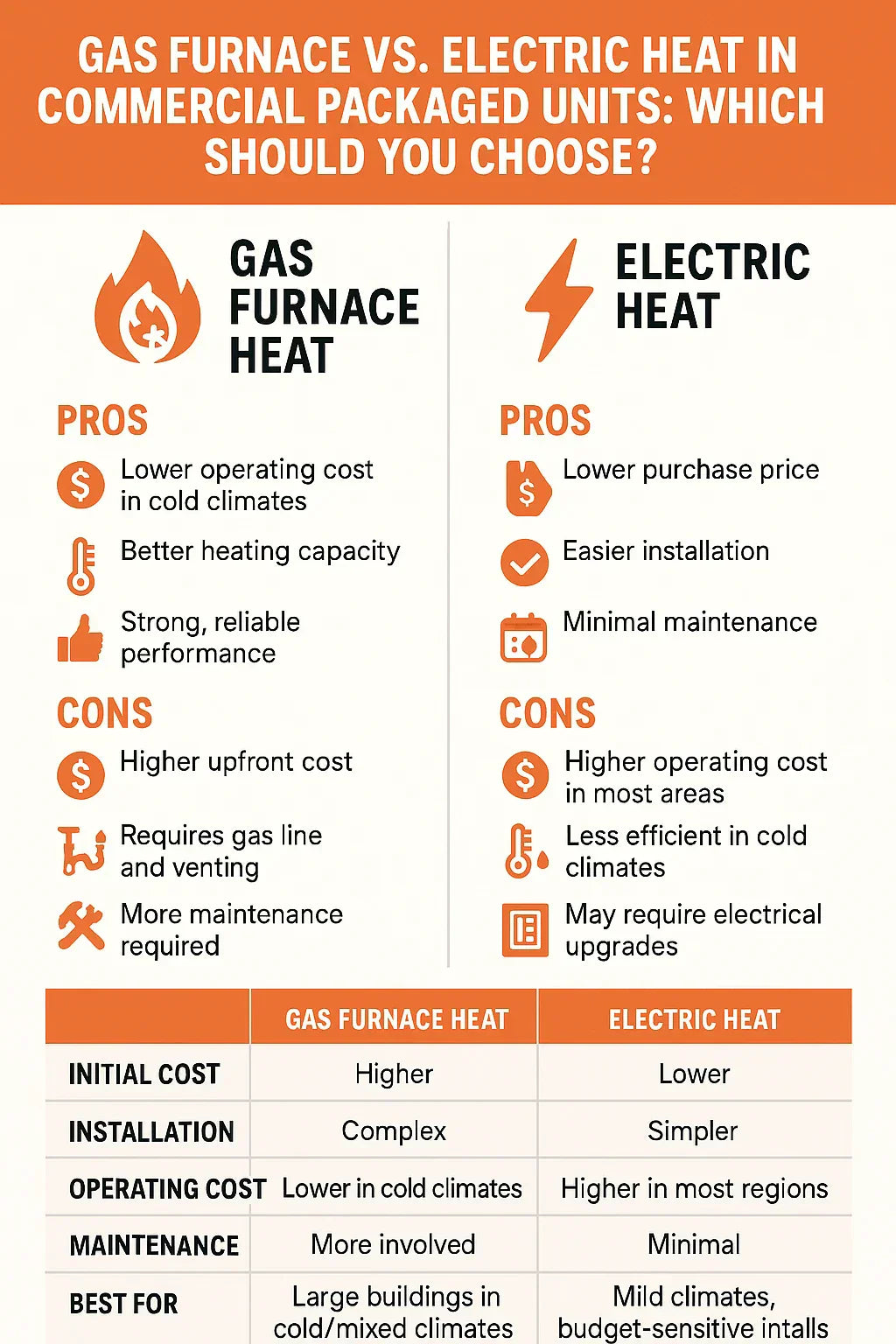

📊 4. Side-by-Side Comparison Table

| Feature | Gas Furnace Heat | Electric Heat |

|---|---|---|

| Upfront Cost | Higher (unit + gas line work) | Lower (unit + simple install) |

| Install Complexity | Requires venting, gas piping | Requires adequate electrical capacity |

| Operating Cost | Lower in cold climates, variable in mild zones | Higher in most regions |

| Performance | Strong, steady heat even in extreme cold | Adequate in mild/moderate climates |

| Maintenance | More involved: burners, heat exchanger checks | Minimal: coil and relay inspection |

| Safety | Requires combustion safety checks | No combustion gases |

| Lifespan | 15–20 years with maintenance | 12–15 years average |

| Best For | Large buildings in cold/mixed climates | Mild climates, budget-sensitive installs |

💵 5. Cost Considerations in 2025

Equipment Pricing:

-

Gas furnace packaged units: $7,500–$20,000+ installed (depending on tonnage & efficiency).

-

Electric heat packaged units: $6,000–$18,000+ installed.

Installation Costs:

-

Gas models need licensed gas fitters, venting, and possibly trenching for new service lines—adds $1,500–$5,000.

-

Electric models may require electrical service upgrades—adds $1,000–$4,000.

Operating Costs per Million BTUs (2025 est.):

-

Natural Gas: $10–$16 (region-dependent).

-

Electricity: $25–$35 (based on $0.12–$0.16/kWh).

Rebates & Incentives:

-

Gas utilities sometimes offer furnace rebates in cold regions.

-

Electric models may qualify for renewable energy or demand-side management credits in certain states.

🌡 6. Climate & Building Type Recommendations

Cold Climates (Midwest, Northeast):

Go gas if your winters regularly drop below freezing—electric heat becomes costly and less efficient.

Mild Climates (Southeast, Southwest):

Electric heat may be more cost-effective since heating demand is low. Simpler install = lower project cost.

Industrial / Warehouses:

Gas is usually preferred—fast recovery time and high output for big spaces.

Office / Retail:

If your heating needs are moderate and you value low install cost, electric heat can work—especially if you already have strong electrical infrastructure.

🛠 7. Maintenance & Service Factors

Gas Furnace Packaged Units:

-

Annual burner and ignition inspection.

-

Heat exchanger integrity checks (safety-critical).

-

Flue/vent inspection.

-

Filter changes.

Electric Heat Packaged Units:

-

Check heating coils for wear or corrosion.

-

Inspect relays and electrical connections.

-

Ensure adequate airflow to prevent coil overheating.

📑 8. Jake’s Real-World Scenarios

Scenario 1 – Midwest Warehouse (Gas)

We swapped a 10-ton electric unit for a gas model. Winter bills dropped ~35%, and the building heated faster during early shifts.

Scenario 2 – Florida Office (Electric)

Chose electric for a 6-ton packaged unit. Minimal heating load, so operating cost differences were negligible—saved ~$4,000 on install.

Scenario 3 – Colorado Retail + Office Hybrid (Gas)

Gas provided the heating power needed for retail customers and office staff in winter, plus worked well with the building’s existing rooftop layout.

✅ 9. Summary & Decision Checklist

Pick Gas If:

-

You’re in a cold or mixed climate.

-

You have access to affordable natural gas or propane.

-

Your building has high heating demand.

Pick Electric If:

-

You’re in a mild climate.

-

Installation budget is tight.

-

Your building has low winter heating requirements.

Jake’s Quick Checklist:

-

Climate analysis done?

-

Local fuel vs. electric rates compared?

-

Utility rebate eligibility checked?

-

Existing infrastructure evaluated (gas line vs. electrical panel)?

-

Long-term operating cost projections made?

In the next topic we will know more about: Energy Efficiency in Large Packaged Units: Understanding EER, IEER, and Gas Furnace AFUE