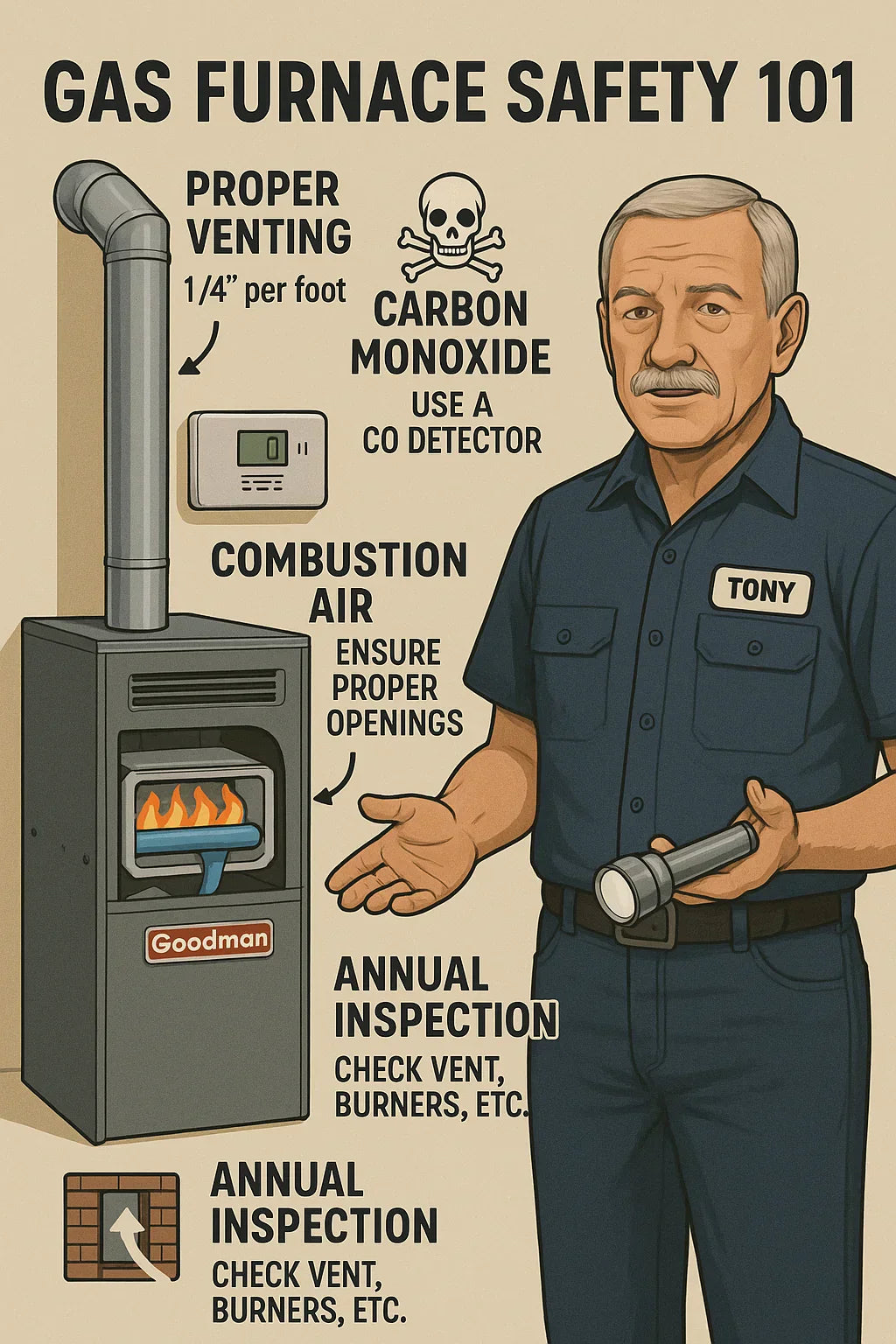

Tony’s Field Guide to Keeping Your Home Safe and Your Furnace Healthy

When Tony installs or services a furnace, there’s one thing he always tells homeowners before he leaves:

“Heat is comfort — safety is survival. If your furnace isn’t venting right or burning clean, it’s not just inefficient, it’s dangerous.”

Gas furnaces like the Goodman 80% AFUE 120,000 BTU Two-Stage Natural Gas Furnace (Model GR9T801205DN) are built with safety in mind — pressure switches, flame sensors, rollout switches, and sealed chambers. But even the best system can turn into a hazard if it’s neglected or poorly vented.

This guide covers everything Tony wants homeowners to know about furnace safety — from understanding how gas combustion works to preventing carbon monoxide (CO) leaks, inspecting venting, and knowing when to call a professional.

🏠 Comfort Means Nothing Without Safety

Tony remembers a call one winter in Ohio: a homeowner reported headaches and dizziness after their furnace had “been acting funny.”

“I walked in with my CO detector and it was reading 48 ppm — anything above 35 ppm is unsafe. Turns out a bird had built a nest in the vent pipe.”

That’s why he’s so strict about teaching safety first. A gas furnace should never be a guessing game.

Furnace safety has three main pillars:

-

Proper combustion — clean, blue flame, no soot.

-

Proper venting — exhaust gases leaving the home effectively.

-

Proper monitoring — CO detection and annual inspections.

🔥 How a Gas Furnace Burns Fuel — Tony’s Simple Breakdown

Before you can spot a problem, you need to know how the system works.

The Goodman GR9T801205DN uses natural gas as its fuel source. The process works like this:

-

The gas valve opens and sends gas to the burners.

-

The inducer motor starts up, drawing combustion air through the burners.

-

The igniter sparks or glows, igniting the gas mixture.

-

The heat exchanger heats up as flames pass through it.

-

The blower motor pushes warm air through your ducts — separate from the combustion air.

-

Exhaust gases exit through the vent or flue pipe.

What Clean Combustion Looks Like

-

Steady blue flames with a small inner cone.

-

No flickering, sputtering, or orange tips.

-

Quiet, even ignition (a single click → whoosh).

“If the flame’s yellow or noisy, that means it’s not burning right — and that means danger.”

🔗 Learn: Energy.gov – How Furnaces Work

🧱 Venting Systems: The Furnace’s Lifeline

Your furnace’s vent is its breathing tube — it exhausts all combustion gases (CO, CO₂, nitrogen oxides, and water vapor) safely outside.

The Goodman 80% model uses Type B metal venting, also called “natural draft.” It relies on heat to create upward flow.

Tony’s Venting Checklist

-

Proper Slope:

-

Minimum ¼ inch rise per foot of horizontal vent.

-

Keeps exhaust moving and prevents condensation.

-

-

No Sags or Dips:

-

Sagging pipes collect moisture and restrict draft.

-

-

Secure Connections:

-

All joints sealed with foil HVAC tape, not duct tape.

-

-

Adequate Clearance:

-

Keep vent 3 inches away from any combustible materials.

-

-

Rust or White Streaks:

-

Indicate moisture condensation — a sign of poor venting.

-

“If your flue looks like it’s sweating or rusting, that’s your furnace crying for help.”

🔗 Reference: NFPA 54 – National Fuel Gas Code

🧰 Combustion Air: The Forgotten Safety Factor

Tony says, “Every flame needs air — even the clean ones.”

In older homes, natural airflow often supplied plenty of oxygen for combustion. But newer, tightly sealed homes can choke furnaces of air, causing backdrafting — when exhaust gases, instead of leaving, flow back into your home.

Tony’s Rule of Thumb

You need 1 square inch of air opening per 4,000 BTUs of furnace input.

For a 120,000 BTU furnace, that’s 30 square inches total — ideally split between:

-

One high vent (near ceiling)

-

One low vent (near floor)

Tony’s warning:

“I’ve seen homeowners drywall over their furnace closet louvers to make it ‘look nicer.’ That’s a CO trap waiting to happen.”

Always make sure your furnace room has adequate airflow and isn’t airtight.

🔗 Reference: ASHRAE – Combustion Air Standards

☠️ Carbon Monoxide: The Silent Killer

Carbon monoxide is invisible, odorless, and potentially lethal. It forms when natural gas doesn’t burn completely — often due to restricted airflow, dirty burners, or cracks in the heat exchanger.

Tony never works without his portable CO detector clipped to his shirt.

CO Levels and What They Mean

| CO Level (ppm) | Exposure Time | Health Impact |

|---|---|---|

| 0–9 | Continuous | Safe |

| 10–34 | Hours | Mild headache, fatigue |

| 35–50 | 1–4 hours | Dangerous, nausea |

| 100+ | <1 hour | Life-threatening |

“You can’t smell CO. By the time you feel dizzy, you’re already in trouble.”

Tony’s CO Safety Rules

-

Install CO detectors on every level of your home.

-

Test them monthly and replace every 5–7 years.

-

Never run your furnace without a filter — blocked airflow can cause incomplete combustion.

-

Schedule an annual combustion analysis with a professional.

🔗 Source: CDC – Carbon Monoxide Poisoning Prevention

🔍 Signs of Unsafe Combustion or Venting

Tony trains his eyes for small clues that tell big stories.

| Warning Sign | What It Means | Tony’s Advice |

|---|---|---|

| Yellow or flickering flames | Dirty burners or poor oxygen | Clean or service burners |

| Rust or white streaks on vent pipe | Condensation or backdrafting | Check vent slope |

| Moisture on furnace top | Exhaust recirculating | Inspect flue draft |

| Soot near burner door | CO leakage | Shut down immediately |

| Headaches or nausea indoors | CO buildup | Evacuate & call utility company |

“A furnace will always tell you what’s wrong — you just have to know how to read the signs.”

🧯 Tony’s Annual Safety Inspection

Every fall, before firing up furnaces for the season, Tony runs a 10-step safety checklist.

✅ The 10-Point Furnace Safety Inspection

-

Inspect vent system for rust, blockages, and secure connections.

-

Test draft pressure with a manometer to confirm proper airflow.

-

Check CO levels near burners and registers.

-

Examine heat exchanger for cracks, rust, or distortion.

-

Test gas pressure (3.5” WC for natural gas).

-

Clean flame sensor and burners.

-

Verify safety switches (rollout, limit, pressure).

-

Inspect blower motor bearings and capacitor.

-

Test ignition sequence and flame stability.

-

Check for backdrafting at the flue collar using smoke.

“One hour once a year is all it takes to keep a safe furnace safe.”

⚙️ The Heat Exchanger: The Unsung Hero of Safety

The heat exchanger is what separates toxic combustion gases from breathable indoor air. It’s made of aluminized steel in the Goodman GR9T801205DN — corrosion-resistant but still vulnerable over time.

Cracks or holes can allow CO to seep into your ducts.

Tony’s test:

-

Uses a mirror and flashlight to inspect surfaces.

-

Runs a combustion analyzer to check for CO traces in airflow.

If readings are elevated, it’s not repairable — the exchanger must be replaced.

“A cracked heat exchanger isn’t negotiable. You can’t tape it, patch it, or wish it better. You replace it or replace the furnace.”

🔋 Safety Devices That Save Lives

Tony installs these in every furnace room he works in — and so should you.

| Device | Function | Cost | Tony’s Rating |

|---|---|---|---|

| Carbon Monoxide Detector | Monitors CO levels | $30–$50 | ⭐⭐⭐⭐⭐ |

| Smoke Detector | Detects fires early | $20 | ⭐⭐⭐⭐ |

| Natural Gas Alarm | Detects methane leaks | $40 | ⭐⭐⭐⭐ |

| Surge Protector | Prevents board burnout | $30 | ⭐⭐⭐⭐⭐ |

“The best upgrades aren’t always high-tech. Sometimes they’re just smart.”

🧠 Tony’s Everyday Safety Tips

-

Keep 3 feet of clearance around the furnace — no storage, no boxes.

-

Never block combustion air vents.

-

Clean filters regularly — airflow = safety.

-

Label gas shutoff valves clearly.

-

Check vent termination outside after storms.

-

Test CO alarms monthly.

“You don’t have to be paranoid — just prepared.”

🧾 Tony’s Annual Furnace Safety Budget

| Task | Cost | Frequency |

|---|---|---|

| Professional Tune-Up | $120–$200 | Yearly |

| CO Detector Replacement | $40 | Every 5 years |

| Vent Sealing/Repair | $50–$150 | As needed |

| Heat Exchanger Inspection | Included | Annually |

Tony compares it to car maintenance:

“You’d never skip an oil change — don’t skip a furnace tune-up. Same principle, higher stakes.”

💬 Tony’s Takeaway: “Safety Comes Before Efficiency”

“An efficient furnace is great. A safe furnace is essential. If your vent’s clogged, your flame’s yellow, or your detector’s missing — none of that SEER or AFUE stuff matters.”

The Goodman GR9T801205DN is engineered with smart safety features, but safety is a partnership between design and diligence. With clean vents, steady combustion, and proper CO detection, you’ll stay warm and safe for decades.

“You don’t need to be an HVAC pro — you just need to care enough to check.”

✅ Final Word

Gas furnace safety isn’t about fear — it’s about awareness. Tony’s 25 years in the field have shown him that nearly every dangerous situation started with one thing: neglect.

By keeping your Goodman 120,000 BTU two-stage furnace properly vented, monitored, and maintained, you’ll protect your family and ensure your system operates exactly as designed — safely, quietly, and efficiently.

“Heat is comfort. Safety is peace of mind. And peace of mind? That’s priceless.”

In the next topic we will know more about: R-32 & Natural Gas Systems: How These Technologies Can Work Together