🏠 Sizing Isn’t Just About the System — It’s About the Path the Air Takes

You can install the perfect-sized HVAC unit — but if your air isn’t moving efficiently, your comfort won’t follow.

Think of your system like a pair of lungs. The equipment is the heart, but the ducts and vents are the arteries and veins. If they’re clogged, narrow, or poorly designed, airflow slows, pressure builds, and your whole system strains.

The Air Conditioning Contractors of America (ACCA) estimates that up to 70% of HVAC performance problems stem not from the system itself — but from duct design and airflow issues.

In this Savvy breakdown, we’ll explore why airflow is half the battle in proper sizing, how to diagnose duct-related comfort problems, and what design choices make your HVAC system perform like it’s custom-built for your home.

🌬️ 1. Airflow: The Unsung Hero of HVAC Efficiency

Airflow is the medium that carries heating and cooling energy through your home. When it moves properly — at the right velocity and volume — every room feels even and efficient. When it doesn’t, you feel the effects instantly.

Signs of Poor Airflow:

-

Hot or cold spots across rooms

-

Excessive noise from vents

-

Weak air from some registers

-

System runs longer without hitting set temperature

-

High utility bills despite high-efficiency equipment

Without balanced airflow, even a perfectly sized system behaves like an undersized or oversized one, wasting power while failing to deliver comfort.

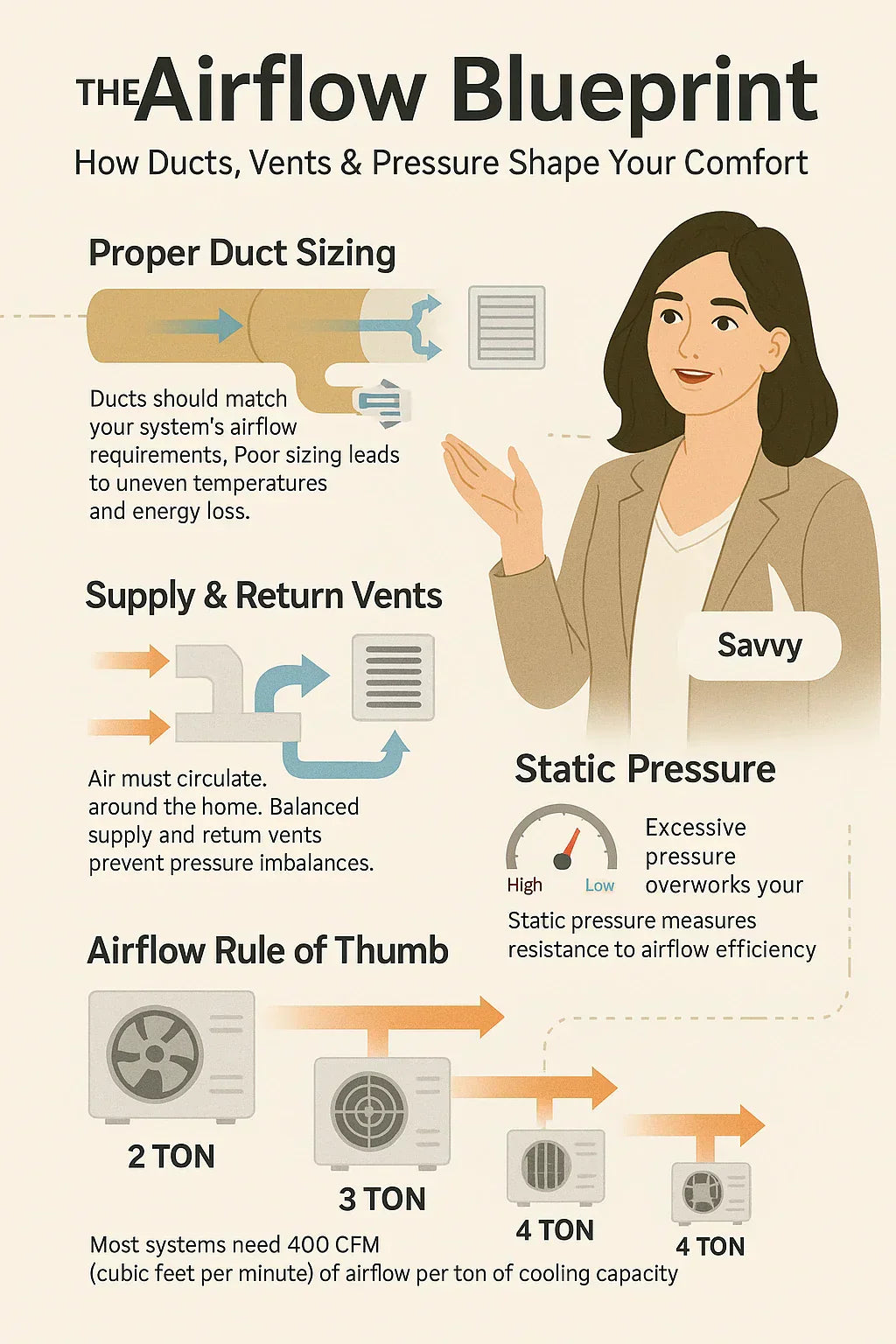

⚙️ 2. Understanding Static Pressure — The “Blood Pressure” of Your System

Static pressure measures how much resistance air faces as it moves through ducts, filters, and vents.

If pressure is too high, your blower fan struggles, energy use spikes, and your equipment wears out faster.

Too low? Air moves too quickly, reducing dehumidification and creating noisy drafts.

According to Energy.gov, maintaining proper airflow — typically around 400 CFM per ton — is essential for keeping both comfort and efficiency in balance.

Ideal Static Pressure Range:

-

0.5 inches of water column (in. w.c.) = balanced system

-

Above 0.8 in. w.c. = restrictive ductwork

-

Below 0.3 in. w.c. = leaks or poor return airflow

A quick static pressure test by an HVAC pro can reveal whether your system’s airways are helping or hurting performance.

📏 3. Duct Sizing — The Most Overlooked Part of HVAC Design

Your ducts must deliver enough CFM (Cubic Feet per Minute) of airflow to match your system’s output.

If they’re too small, your system overworks. Too large, and air loses velocity, reducing efficiency.

Example:

A 3-ton system (36,000 BTUs) needs about 1,200 CFM of airflow.

If your ducts are sized for only 800 CFM, you’ve effectively turned your 3-ton system into a 2-ton one.

ENERGY STAR’s Duct Design Guide recommends duct sizing within ±10% of target airflow to ensure optimal performance.

🌀 4. Return Air: The Other Half of the Equation

Supply ducts push conditioned air into rooms. Return ducts pull it back for recirculation.

If your returns are undersized, missing, or poorly placed, your system becomes unbalanced.

What Happens with Poor Return Air:

-

Rooms near the air handler get too much airflow

-

Far rooms stay stuffy

-

Pressure differences cause doors to slam or “whoosh” when opening

-

Energy efficiency drops as your blower fights resistance

Savvy Tip:

For every cubic foot of air your system supplies, the same amount must return. Add dedicated returns in large rooms or upper floors to equalize pressure.

🔄 5. The 400 CFM Rule — How Airflow and Tonnage Intersect

Every ton of air conditioning capacity requires roughly 400 cubic feet per minute of airflow.

Here’s how that breaks down:

| System Size | Required Airflow (CFM) | Common Duct Size |

|---|---|---|

| 2 Ton | 800 CFM | 12-inch round main trunk |

| 3 Ton | 1,200 CFM | 14-inch round main trunk |

| 4 Ton | 1,600 CFM | 16-inch round main trunk |

| 5 Ton | 2,000 CFM | 18-inch round main trunk |

If your ductwork doesn’t match your system’s tonnage, your equipment will struggle — just like trying to breathe through a straw.

🔍 6. Airflow Bottlenecks — Where Systems Lose Power

Even with proper duct size, airflow can suffer from:

-

Bends and kinks in flexible ducts

-

Dirty filters or coils blocking flow

-

Closed or blocked registers

-

Improperly sealed joints causing air leakage

According to Lawrence Berkeley National Laboratory, the average home loses 20–30% of conditioned air through duct leaks.

That’s like running your system on “eco mode” all the time — except it’s not saving you anything.

Savvy Fix:

Have your ducts pressure-tested and sealed with mastic or foil-backed tape (not duct tape!). Well-sealed ducts can save $200–$400 annually on energy bills.

🧰 7. The Art of Duct Layout — Straight, Smooth, and Balanced

Duct design follows physics, not guesswork.

The smoother and straighter your duct paths are, the easier your blower moves air through them.

Ideal Layout Principles:

-

Keep main trunks as straight as possible

-

Limit sharp bends (use 45° instead of 90° turns)

-

Branch ducts should gradually reduce in size toward the end

-

Use balancing dampers in long runs for even distribution

If your duct system looks like spaghetti, your airflow will perform like it too.

🧱 8. Room Vents and Diffusers — The Finishing Touch on Airflow

Once air reaches the room, vent placement decides how well it mixes.

Poorly positioned vents can cause drafts, stagnant pockets, or uneven temperatures.

Best Practices:

-

Install supply vents high on walls or ceilings for cooling, low for heating.

-

Place return vents opposite the supplies for balanced circulation.

-

Avoid blocking vents behind furniture or curtains.

The ASHRAE Fundamentals Handbook emphasizes diffuser design as a key comfort factor—air must mix, not blast, to feel natural.

🌡️ 9. Static Pressure and Humidity: The Invisible Connection

When airflow is restricted, the evaporator coil can’t exchange heat efficiently.

That causes two problems:

-

Coil freezing during cooling mode.

-

Poor humidity removal due to short run times.

The EPA Indoor Air Quality Program warns that high humidity (above 55%) accelerates mold growth and decreases comfort even at the same temperature.

Good airflow isn’t just about cooling—it’s about controlling moisture, too.

⚙️ 10. Modern Fixes: Variable-Speed Blowers and Smart Airflow Control

Traditional single-speed blowers operate at one power level—on or off.

Modern variable-speed systems, like the Goodman 3 Ton 15.2 SEER2 System, adjust fan speed dynamically to maintain perfect airflow under any condition.

Benefits:

-

Maintains ideal static pressure

-

Reduces noise and drafts

-

Extends lifespan of filters and coils

-

Enhances humidity control

When paired with zoning or smart thermostats, your airflow can respond to each room’s unique needs—maximizing both comfort and efficiency.

🧠 11. Duct Testing and Balancing — The Diagnostic You Didn’t Know You Needed

A duct balance test measures actual airflow in each branch of your system using anemometers and pressure sensors.

It identifies where air velocity drops, pressure builds, or leaks occur.

After balancing, your HVAC system typically:

-

Delivers 20–30% more effective airflow

-

Runs quieter

-

Reduces runtime by 15–25%

If you’ve ever thought, “This room just never feels right,” duct balancing might be the missing solution.

📊 12. Real-World Example: The 3-Ton System That Felt Like 2

Home: 1,800 sq ft single-story in Florida

System: 3-ton 15.2 SEER2 Goodman unit

Problem: Uneven cooling and high humidity despite new equipment

Inspection Findings:

-

Ducts undersized for total CFM (10-inch instead of 12-inch mains)

-

Only one return vent in entire home

-

High static pressure at 0.9 in. w.c.

Fix:

-

Added second return grille

-

Upsized main duct and sealed leaks

-

Balanced dampers and recalibrated thermostat

Result:

System airflow increased from 850 to 1,200 CFM.

Humidity dropped by 12%.

Energy bills decreased by 18%.

Same equipment. Better airflow. Completely different comfort level.

🧩 13. The Airflow Formula for Homeowners

You don’t have to be an engineer to think like one.

Here’s the simplified version of Savvy’s Airflow Formula:

When those elements align, even modest systems outperform their specs.

It’s proof that sizing isn’t about buying bigger—it’s about breathing better.

💡 14. Savvy’s Airflow Upgrade Tips

✅ Seal duct leaks with mastic, not tape.

✅ Insulate ducts in unconditioned spaces.

✅ Clean filters monthly and replace every 60–90 days.

✅ Check static pressure annually.

✅ Add returns in large or isolated rooms.

✅ Balance airflow after any remodel or duct change.

✅ Upgrade to variable-speed blowers when replacing equipment.

Small airflow fixes can make a 15-year-old system feel brand new.

💬 15. Savvy’s Takeaway: Airflow Is Sizing’s Secret Weapon

Your system’s tonnage and SEER rating set the potential — but airflow unlocks it.

It’s what turns calculated BTUs into real, felt comfort.

Before upgrading to a larger system, inspect your ducts, measure your pressure, and test your airflow.

Because in HVAC, it’s not just what you install — it’s how you move it.

So the next time your home feels uneven, don’t blame the system. Blame the bottlenecks.

Then let a properly designed airflow plan make your 3-ton Goodman perform like a dream.

Buy this on Amazon at: https://amzn.to/4hyDyKH

In the next topic we will know more about: The Sizing Sweet Spot — Balancing Power, Efficiency, and Comfort in 2025 Homes