When people talk about heater maintenance, they obsess over burners and flames—and for good reason. But if the fan, blower, and motor assembly isn’t doing its job, even the cleanest flame in the world won’t heat your space properly.

This is the part of your Reznor propane heater that works every single time the unit runs, quietly pushing heat where it needs to go. When it’s dirty, loose, or worn out, you’ll see higher propane bills, uneven heat, nuisance shutdowns, and motors that fail long before their time.

Reznor UDX 60,000 BTU Propane Unit Heater

I’ve replaced a lot of blower motors that didn’t need replacing. They just needed cleaning and tightening years earlier.

This guide walks you through annual fan, blower, and motor care—what to clean, what to inspect, what to lubricate (and what not to), and how to catch problems before they get expensive.

🧯 Safety First: Lock It Out Before You Touch It

Before opening the cabinet:

-

Turn OFF power at the disconnect

-

Shut OFF propane supply (recommended)

-

Let the unit cool completely

-

Use gloves and eye protection

-

Secure your ladder if the unit is ceiling-mounted

Never spin the blower by hand with power connected. Ever.

🧠 Why the Blower System Matters More Than You Think

Your blower system is responsible for:

-

Moving heat off the heat exchanger

-

Preventing overheating

-

Delivering even temperature throughout the space

-

Keeping safety switches happy

Restricted airflow =

-

High heat exchanger temperatures

-

Short cycling

-

Limit switch trips

-

Reduced heater lifespan

In short: bad airflow kills good heaters.

🧰 Tools You’ll Need

This job doesn’t require specialty gear:

-

Shop vacuum with brush attachment

-

Compressed air

-

Nut drivers or socket set

-

Flashlight or headlamp

-

Straightedge or ruler

-

Light machine oil (only if motor is oilable)

Optional but helpful:

-

Clamp meter (for motor amp draw)

-

Infrared thermometer

🔍 Step 1: Visual Inspection of the Blower Assembly

Once the access panel is removed, inspect the entire blower section.

Look for:

-

Heavy dust or debris on blades

-

Rust or corrosion

-

Bent or damaged fan blades

-

Loose mounting bolts

-

Oil residue or discoloration

If the blower looks dirty, it is dirty enough to affect airflow.

🧹 Step 2: Clean the Blower Wheel (This Matters a Lot)

Blower wheels act like dust magnets.

Why dirt hurts performance:

-

Reduces airflow

-

Throws the wheel out of balance

-

Increases motor load

-

Causes vibration and noise

How to clean it:

-

Vacuum loose debris

-

Brush each blade carefully

-

Blow compressed air from the inside out

-

Rotate the wheel to reach all sides

Do NOT:

-

Use water

-

Bend blades

-

Scrape aggressively

🔗 Airflow and heating efficiency basics:

https://www.energy.gov/energysaver/home-heating-systems

⚙️ Step 3: Check Blower Balance and Alignment

An unbalanced blower is a silent motor killer.

Check for:

-

Wobble when spinning by hand

-

Uneven spacing between blades

-

Rubbing against housing

-

Excessive vibration during operation

If the wheel wobbles, it’s either dirty, damaged, or loose on the shaft.

Action:

Clean first. If wobble remains, tighten the set screw or mounting hub.

🔩 Step 4: Tighten All Mounting Hardware

Reznor heaters vibrate. Over time, hardware loosens.

Check and tighten:

-

Motor mount bolts

-

Blower housing fasteners

-

Set screws on the blower wheel

-

Support brackets

Loose mounts lead to noise complaints and premature bearing wear.

This is one of the highest-value maintenance steps you can do.

🔌 Step 5: Inspect the Motor (Eyes and Ears)

Before worrying about replacement, inspect the motor itself.

Look for:

-

Burnt wiring insulation

-

Oil leakage

-

Rust at the shaft

-

Overheating discoloration

Listen for:

-

Grinding

-

Squealing

-

Clicking

-

Humming without rotation

Any of those noises are early warnings—not instant death sentences.

🛢️ Step 6: Motor Lubrication (Only If Allowed)

Some blower motors are sealed. Some are oilable.

Rule of thumb:

-

If there are oil ports → light oil only

-

If sealed → do not oil

How to oil properly:

-

Use non-detergent light machine oil

-

2–3 drops per port

-

Do not over-oil

Over-lubrication attracts dust and causes bearing failure.

🔗 Motor maintenance basics:

https://www.energy.gov/eere/buildings/electric-motors

⚡ Step 7: Electrical & Amp Draw Check (Optional but Smart)

If you have a clamp meter:

-

Measure motor amp draw during operation

-

Compare to motor nameplate rating

High amp draw means:

-

Dirty blower

-

Mechanical resistance

-

Failing motor windings

Cleaning often drops amp draw immediately.

🌬️ Step 8: Verify Airflow Path Is Clear

Even a clean blower can’t move air through a blocked path.

Inspect:

-

Intake screens

-

Discharge louvers

-

Nearby stored items

-

Dust buildup around air outlets

Reznor heaters need clear space to breathe.

🔗 Ventilation & airflow safety:

https://www.nfpa.org/education-and-research/home-fire-safety/heating

🔄 Step 9: Test Run & Listen

Restore power and run the heater.

Listen for:

-

Smooth startup

-

No rattles

-

No whining or vibration

-

Steady airflow sound

Feel for:

-

Strong, even air movement

-

No hot spots at the unit

If it sounds smoother after cleaning, you did it right.

⚠️ When to Stop DIY and Call a Pro

Call a technician if you see:

-

Motor overheating repeatedly

-

Bearings screaming even after lubrication

-

Amp draw exceeding nameplate

-

Persistent vibration you can’t correct

-

Blower shaft damage

Motors fail slowly—catching them early saves money.

🧠 Why Blower Maintenance Saves Propane

Dirty blowers:

-

Move less air

-

Cause longer run times

-

Trigger safety limits

-

Waste fuel

Clean blowers:

-

Transfer heat efficiently

-

Reduce run cycles

-

Extend heat exchanger life

-

Lower propane use

This is quiet efficiency—easy to miss, expensive to ignore.

🔗 Heating efficiency overview:

https://www.energystar.gov/products/furnaces

🗂️ Step 10: Document the Service

Log:

-

Cleaning date

-

Motor condition

-

Noise observations

-

Lubrication performed

-

Any concerns

Patterns tell you when parts are aging.

🔗 Manufacturer support reference:

https://www.reznorhvac.com

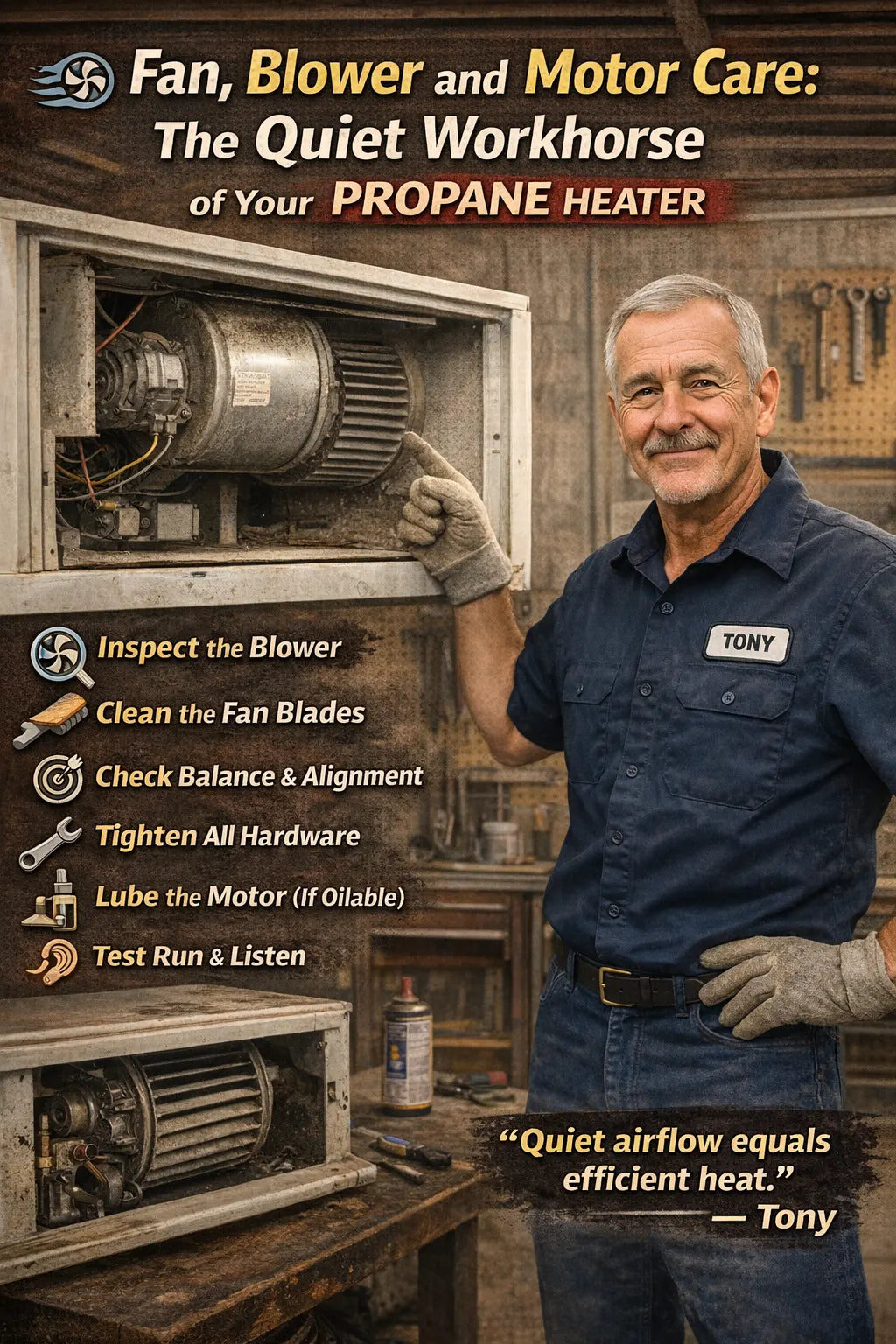

🏁 Final Word from Tony

Burners make the heat—but the blower delivers it.

If you clean and inspect your fan, blower, and motor once a year, you’ll:

-

Hear less noise

-

Burn less propane

-

Avoid surprise motor failures

-

Get more life out of your heater

This is the maintenance nobody brags about—but every smart shop owner does.

Buy this on Amazon at: https://amzn.to/4oCrGcV

In the next topic we will know more about: Venting and Combustion Air: Keep the Breath of Your Heater Clean