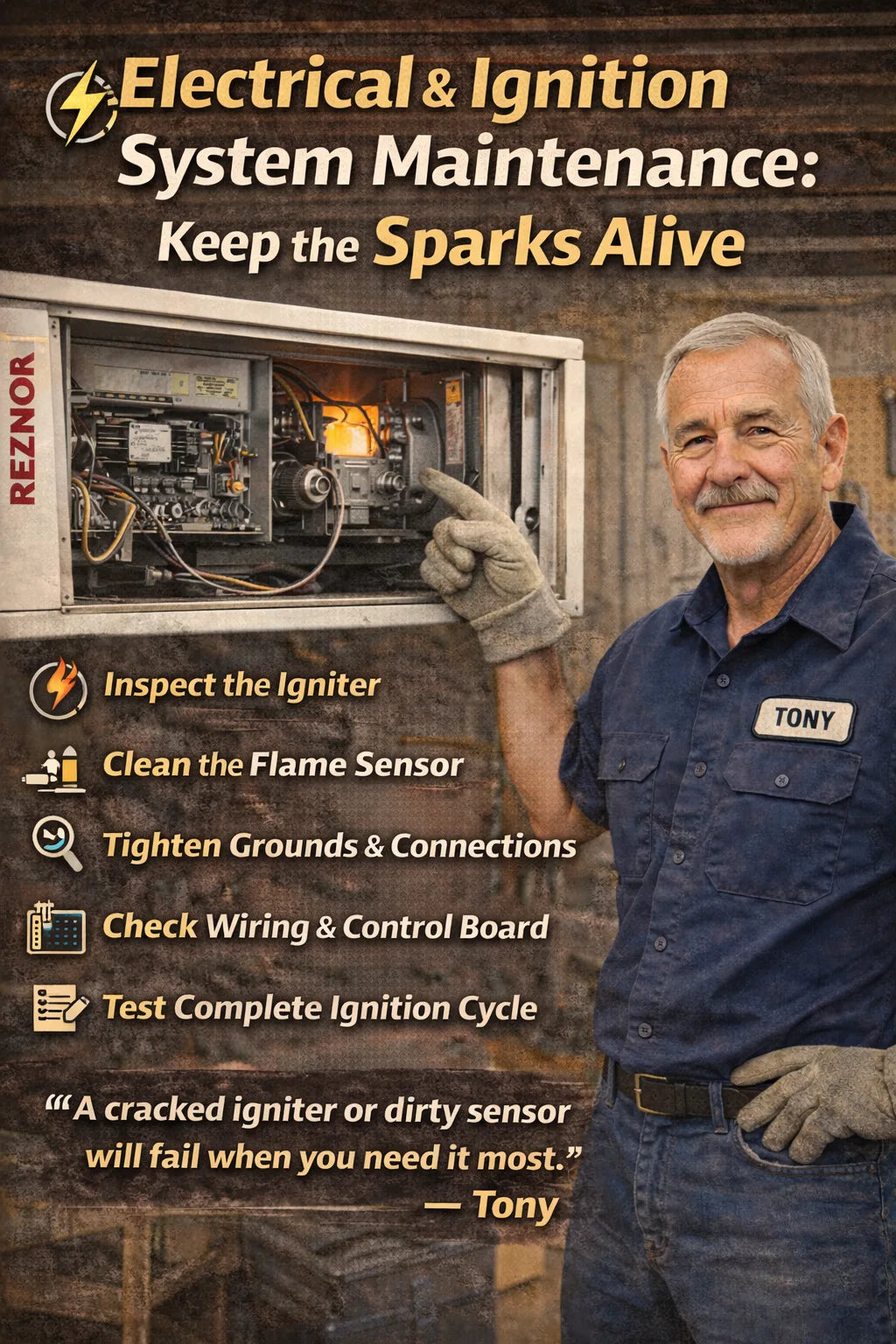

Your Reznor propane heater can have clean burners, perfect airflow, and a spotless heat exchanger—but if the electrical and ignition system is weak, dirty, or loose, the heater won’t light reliably. Or worse, it’ll light once, shut down, and leave you chasing ghosts.

Most ignition problems I see aren’t “bad parts.” They’re dirty sensors, tired igniters, loose grounds, or cracked wires that could’ve been caught in minutes during annual maintenance.

Reznor UDX 60,000 BTU Propane Unit Heater

This guide walks you through how the ignition system works, what to inspect and clean, what to test, and when to stop and call a pro—so your heater sparks when it should and stays lit when it matters.

🧯 Safety First: Electricity + Propane Demands Respect

Before you open the cabinet:

-

Turn OFF power at the disconnect

-

Shut OFF propane if working near gas components

-

Let the heater cool completely

-

Wear gloves and eye protection

-

Never bypass safety switches or controls

If you smell propane or see damaged wiring, stop immediately.

🧠 How the Reznor Ignition System Works (Quick Primer)

Understanding the sequence helps you diagnose fast:

-

Thermostat calls for heat

-

Control board checks safety switches

-

Inducer/combustion airflow is verified

-

Igniter energizes

-

Gas valve opens

-

Flame lights

-

Flame sensor proves flame

-

Heater continues running

If any step fails, the system shuts down on purpose. That’s safety—not failure.

🔍 Step 1: Start With a Visual Electrical Inspection

Open the service panel and take a slow look before touching anything.

Check for:

-

Burnt or discolored wires

-

Brittle or cracked insulation

-

Loose spade connectors

-

Wires rubbing on sharp metal

-

Signs of moisture or corrosion

Tony’s rule:

If it looks cooked, corroded, or loose—it’s a problem waiting to happen.

🔌 Step 2: Tighten Grounds and Connections (High Value, Low Effort)

Poor grounding causes more ignition issues than most people realize.

Inspect and tighten:

-

Ground wires to the cabinet

-

Control board mounting screws (often part of the ground path)

-

Gas valve ground connections

-

Flame sensor ground reference

A weak ground can mimic a bad control board.

🔥 Step 3: Inspect and Service the Igniter

Igniters are wear items. They don’t last forever—but they should last years if treated right.

Types you’ll see:

-

Hot surface igniters (HSI)

-

Spark igniters (on some models)

Inspect for:

-

Hairline cracks

-

Chips or white spots

-

Loose mounting

-

Improper positioning

Cleaning tips:

-

Use compressed air only

-

Do NOT sand or scrape hot surface igniters

-

Replace if cracked—don’t gamble

🔗 Furnace ignition troubleshooting (DOE):

https://www.energy.gov/energysaver/furnaces-and-boilers

🧪 Step 4: Clean the Flame Sensor (The #1 Shutdown Culprit)

If your heater lights and shuts off after a few seconds, this is almost always the issue.

What the flame sensor does:

It confirms flame by detecting a small electrical current through the flame itself.

How to clean it:

-

Remove the sensor

-

Lightly polish with fine emery cloth

-

Wipe clean—no solvents

-

Reinstall securely

This 5-minute step prevents most nuisance lockouts.

⚙️ Step 5: Check the Gas Valve Electrical Signal

You’re not testing gas pressure here—you’re verifying control.

Inspect:

-

Wiring to the gas valve

-

Tight spade connections

-

No burnt terminals

If the igniter glows but the valve never opens, the issue may be:

-

Control board signal

-

Safety switch preventing valve energizing

-

Loose wiring

This is where diagnosis—not guessing—matters.

🧭 Step 6: Inspect Safety Switches & Limits

Reznor heaters use multiple safeties to prevent unsafe operation.

Common switches include:

-

High-limit switch

-

Rollout switch

-

Pressure switch

Check for:

-

Tripped manual-reset switches

-

Loose wiring

-

Signs of overheating nearby

If a switch trips repeatedly, don’t bypass it—find the cause.

🔦 Step 7: Examine the Control Board (Carefully)

Control boards rarely fail outright—but environment kills them.

Look for:

-

Burn marks

-

Swollen components

-

Corrosion

-

Dust buildup

-

Moisture damage

Maintenance tip:

Gently blow dust off the board with dry air. No cleaners. No brushes.

🔗 Reznor manuals & diagnostics:

https://www.reznorhvac.com

🌬️ Step 8: Check Wiring Routing & Strain Relief

Vibration and heat are enemies of wiring.

Inspect routing for:

-

Wires touching hot surfaces

-

Tight bends at connectors

-

Missing grommets

-

Chafing on sheet metal

A $0.50 grommet can prevent a $500 board failure.

🔄 Step 9: Test the Full Ignition Cycle

Restore power and gas. Call for heat.

Watch the sequence:

-

Inducer/airflow verification

-

Igniter energizes

-

Gas valve opens

-

Flame establishes

-

Flame sensor proves flame

-

Heater continues running

If it fails, note where it fails—that’s your clue.

🚨 Common Symptoms & What They Usually Mean

Igniter glows, no flame:

→ Gas valve signal or propane supply

Flame lights, shuts off quickly:

→ Dirty flame sensor or poor ground

Clicks repeatedly, no ignition:

→ Weak igniter or control issue

No ignition attempt at all:

→ Power, control board, or safety open

Troubleshooting is pattern recognition.

⚠️ When to Stop DIY and Call a Pro

Call a licensed technician if you find:

-

Repeated safety trips

-

Control board damage

-

Gas valve electrical faults

-

Uncertain voltage readings

-

CO detector alarms

Electrical diagnosis beyond visual checks requires meters and experience.

🔗 Carbon monoxide safety (CPSC):

https://www.cpsc.gov/Safety-Education/Safety-Education-Centers/Carbon-Monoxide-Information-Center

🧠 Why Electrical Maintenance Prevents Expensive Failures

Clean, tight electrical systems:

-

Ensure reliable ignition

-

Prevent nuisance shutdowns

-

Reduce component stress

-

Extend control board life

Most “mystery failures” are preventable with basic inspection.

🔗 Propane system safety basics:

https://propane.com/propane-safety-in-your-home/

🗂️ Step 10: Document What You Touched

Log:

-

Igniter condition

-

Flame sensor cleaning

-

Any loose connections corrected

-

Error codes observed

This saves time next season—and protects warranties.

🏁 Final Word from Tony

Ignition systems don’t like dirt, vibration, or loose connections—and Reznor heaters don’t forgive neglect forever.

If you:

-

Clean the flame sensor annually

-

Inspect igniters before they fail

-

Tighten grounds and wiring

-

Keep the control area clean and dry

Your heater will light cleanly, stay running, and avoid those 5 a.m. “why is it cold?” moments.

Keep the sparks alive—and the headaches out.

Buy this on Amazon at: https://amzn.to/4oCrGcV

In the next topic we will know more about: Prep & Protect: Seasonal Shutdown vs. Startup Procedures for Propane Unit Heaters