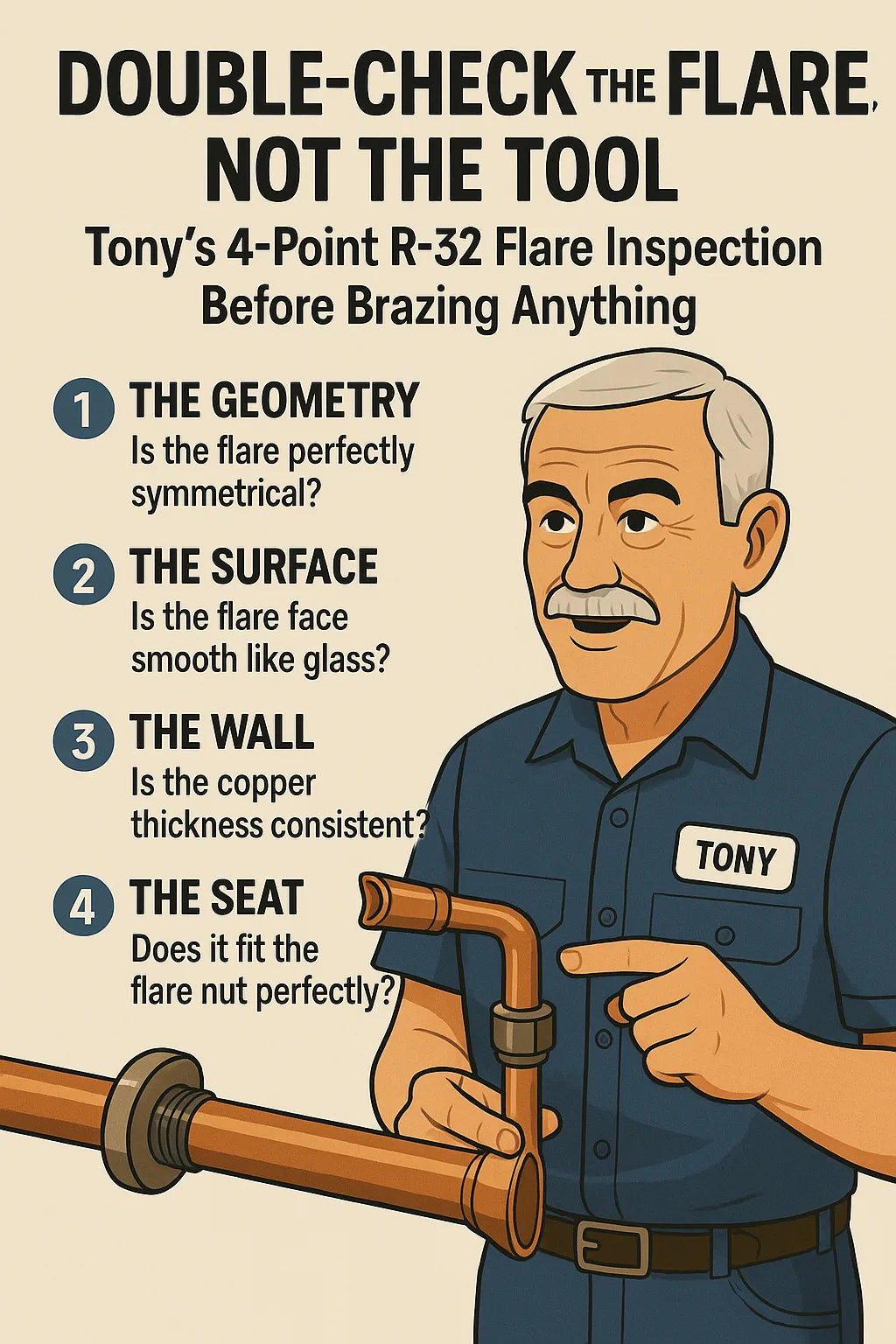

By Tony — because a perfect flare is the difference between a leak-free system and an afternoon you’ll never get back.

🔧 1. Introduction — Why R-32 Flares Aren’t Optional, They’re Surgical

Every installer owns a flare kit.

Every installer thinks they know how to flare copper.

And every installer, at some point, has blamed the flare tool instead of blaming themselves.

But with R-32?

Your workmanship matters more than the tool — because R-32 will expose every flaw instantly.

R-32 runs hotter.

It runs at higher pressure.

It carries heat differently.

It can leak through tiny imperfections that R-410A might’ve tolerated for a season.

That’s why before I braze anything — before I tighten anything — before I pull vacuum — before I pressurize with nitrogen — I run Tony’s 4-Point R-32 Flare Inspection.

If the flare fails any one of these four inspection points, I cut it off and do it again.

Not because I’m picky — but because I hate leaks, callbacks, and explaining to a homeowner why their brand-new Goodman R-32 system is hissing like a tea kettle.

Let’s get into it.

⚙️ 2. Why R-32 Forces You to Rethink Every Flare You Make

Before we dive into the inspection steps, here’s why R-32 demands perfection:

✔️ Higher pressure = less tolerance

R-32 can run 10–15% higher operating pressure than R-410A under similar conditions.

✔️ More heat capacity = more turbulence

Higher heat transport amplifies imperfections inside the flare.

✔️ Lower refrigerant charge = leak sensitivity

Using less refrigerant means even tiny leaks create major performance swings.

✔️ A2L refrigerant = tighter sealing standards

R-32 is mildly flammable (A2L).

Not dangerous if installed correctly — but it mandates leak-tight integrity.

✔️ System oil is sensitive to contamination

Moisture or metal debris from bad flares cooks the POE oil over time.

So if you’re coming to R-32 with your old 410A habits?

Stop.

Start over.

This refrigerant won’t let you be sloppy.

🧰 3. The Problem Isn’t the Tool — It’s the Flare

I’ve seen it a thousand times:

-

“My flaring tool must be worn out.”

-

“This copper doesn’t flare well.”

-

“The nut must be out of tolerance.”

-

“The threads aren’t grabbing.”

Or my favorite:

-

“It’ll seal once I torque it harder.”

No, it won’t.

R-32 doesn’t care how much you crank the wrench.

If the flare is uneven, thin, cracked, or off-center, it will leak.

Your flare must be:

-

Clean

-

Symmetrical

-

Properly lubricated

-

Properly deburred

-

Proper wall thickness

-

Exactly 45 degrees

-

Fully seated

And that leads us to my 4-Point Flare Inspection.

🔍 4. Tony’s 4-Point R-32 Flare Inspection Checklist

This is the inspection every pro uses — or should use — before tightening a single connection.

If it fails ANY of the four points?

You cut it off and redo it.

Period.

1️⃣ Point One: The Geometry — “Is the Flare Perfectly Symmetrical?”

🟦 Icon: 🔵 Geometry / alignment

This is the #1 cause of leaks on R-32 systems.

Your flare must be:

-

perfectly centered

-

evenly distributed

-

free of flat spots

-

identical thickness around the full circle

Tony’s Rule:

If it isn’t symmetrical under a flashlight, it isn’t sealing under pressure.

How to check:

-

Shine a flashlight behind the flare

-

Rotate it slowly

-

Look for thickness variation, uneven lips, or misalignment

-

Inspect both top and bottom at eye level

If you see:

-

one side thinner

-

one area wider

-

uneven brightness

Cut and redo it.

2️⃣ Point Two: The Surface — “Is the Flare Face Smooth Like Glass?”

🟦 Icon: 🔍 Surface inspection

R-32 refrigerant doesn’t like:

-

scratches

-

gouges

-

chatter marks

-

tool swirl

-

rough edges

-

burrs

Anything that interrupts the sealing face creates micro-paths for leaks.

Tony’s Rule:

Your flare face should feel like a stainless countertop — perfect, smooth, clean.

How to check:

-

Run your fingertip around the flare lip

-

Look for visible tooling scratches

-

Shine a bright light across the surface

-

Feel for roughness or irregular texture

If you feel anything other than smooth copper?

Cut and redo.

3️⃣ Point Three: The Wall — “Is the Copper Thickness Consistent?”

🟦 Icon: 📏 Wall thickness

This is the silent killer of flares.

A flare that is:

-

too thin = cracks

-

too thick = won’t seat

-

stretched = weak

-

inconsistent = leaks

Manufacturers specify a flare thickness range, and R-32 installs MUST meet it.

Tony’s Rule:

A flare should never be paper-thin on any side.

How to check:

-

Inspect the cross-section edge

-

Compare thickness around the full circle

-

Look for thinning from over-flaring

-

Ensure no portion is “rolled over” or mushroomed

If any section looks weaker than the rest?

Cut and redo.

4️⃣ Point Four: The Seat — “Does It Fit the Flare Nut Perfectly?”

🟦 Icon: 🧩 Flare seat fit

This is the last and most important part.

Even a perfect flare will leak if it doesn’t seat correctly inside the flare nut.

Common rookie mistakes:

-

Flare too large → won’t nest

-

Flare too small → bites the edge

-

Flare slightly oval → uneven pressure

-

Flare rotated incorrectly

-

Nut cross-threaded

-

Debris inside the nut

Tony’s Rule:

A flare should “click” into place when seated.

If you have to jiggle it, it’s wrong.

How to check:

-

Slide the nut over the flare

-

Gently seat the flare inside the fitting

-

Confirm a smooth, solid, even fit

-

Ensure the flare doesn’t rock or wobble

-

Hand-tighten 1 full turn to confirm no cross-threading

Any movement = redo.

🧯 5. Bonus: Tony’s R-32 Flare Prep Process Before Inspection

If you want your flare to pass inspection every time, you need to prepare the copper like a surgeon, not a plumber.

✔️ Cut with a high-quality tube cutter

Never a hacksaw.

✔️ Deburr lightly

One or two turns only.

Over-deburring thins the copper.

✔️ Ream evenly

No gouging allowed.

✔️ Use flare lubricant

It prevents micro-cracking.

✔️ Use a clutch-type flaring tool

This stops automatically at the correct depth.

✔️ Clean with a lint-free cloth

R-32 oil is extremely sensitive to contamination.

Do all this BEFORE running the 4-point inspection.

🧪 6. The Pressure Truth — Your First Nitrogen Test Doesn’t Lie

Once the flare passes inspection, you torque it to spec (never by feel).

Then you pressurize with 300–450 PSI of nitrogen.

If there’s a flaw, you’ll find out fast.

Signs your flare failed:

-

hissing

-

slow pressure drop

-

micro-bubble formation in soap

-

uneven pressure stabilization

-

temperature drop at fitting

-

nitrogen odor at fitting

A flare that passed Tony’s 4-point test rarely leaks — but nitrogen never lies.

🔩 7. The Biggest Rookie Mistakes Tony Sees on R-32 Flares

Here are the killers:

❌ Over-flaring the copper

Makes the flare paper-thin.

❌ Not deburring the inside edge

Leaves metal fragments that compromise the seal.

❌ Using old, worn flare blocks

Creates an uneven angle.

❌ Under-lubricating the copper

Leads to chatter marks.

❌ Over-torquing to "force the seal"

Destroys the seat and flare.

❌ Rushing the inspection

Every leak starts here.

📘 8. Verified External Technical Resources

Here are reputable, verified external resources supporting coil installation, condensate management, and TXV behavior:

-

ASHRAE Fundamentals – Coil Construction & Airflow (Technical)

https://www.ashrae.org/technical-resources/ashrae-handbook -

HVAC Drainage Code Requirements (ICC)

https://codes.iccsafe.org/ -

EPA HVAC Moisture & Condensate Guidelines

https://www.epa.gov/mold -

AHRI Air Coil Performance Standards

https://www.ahrinet.org/standards -

RSES TXV Installation & Superheat Guidelines

https://www.rses.org -

Goodman (Daikin) Coil & TXV Transition Resources

https://www.daikincomfort.com/

🏁 9. Final Thoughts — A Flare That Passes Tony’s 4-Point Test Never Leaks

Tools matter.

Technique matters.

But inspection matters more than both.

R-32 isn’t forgiving.

It doesn’t care how experienced you are.

It doesn’t care what flare tool you bought.

It doesn’t care how “tight” you think the nut is.

If the flare is wrong, you’ll know.

If the flare is right, you’ll never think about it again.

So remember:

Don’t trust the tool.

Trust the flare.

Inspect it every time.

That’s how pros avoid leaks, callbacks, and late-night emergency repairs.

Buy this on Amazon at: https://amzn.to/47z1067

In the next topic we will know more about: Why Tony Refuses to Seal the Coil Casing Until He Sees the First Frost Pattern