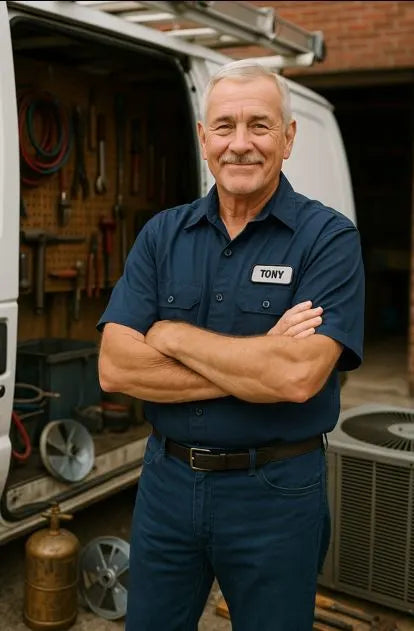

DIY Installation Guide: How Tony Mounted His Amana Wall Unit Without Hiring a Pro

Installing your own through-the-wall AC isn’t rocket science — it’s precision carpentry with a little bit of physics and a whole lot of common sense.

If you’re tired of sweating through summer (and paying pros who charge by the hour just to make a hole in your wall), this guide walks you through how I — Tony — installed the Amana 9,000 BTU 115V Through-the-Wall Air Conditioner with Heat Pump (PBH092J12AA) myself.

I’ve done a dozen installs over the years, and here’s what I’ve learned: do it right once, and your wall unit will quietly serve you for 10+ years.

1. Why I Chose the Amana 9,000 BTU Wall Unit

There are three reasons I went with this specific Amana model:

-

It’s a heat pump, not just an AC — that means year-round comfort.

-

It runs on a standard 115V line, so no electrical rewiring headaches.

-

It’s built like a tank, but quiet enough for a bedroom.

This model hits the sweet spot between power, simplicity, and reliability. I wasn’t interested in gimmicks — I wanted a system that just works, even in the middle of July or January.

👉 For official specs and warranty info, check Amana HVAC’s product page.

2. Planning the Install: Measure Twice, Cut Once

Every successful DIY starts with a tape measure and a plan.

A through-the-wall AC installation requires accuracy — not speed.

Step 1: Choose the Right Wall

Pick a wall that:

-

Has no plumbing or electrical inside.

-

It is exterior-facing (for venting and airflow).

-

It is within reach of a 115V outlet.

-

Has no load-bearing beams in the installation area.

If you’re unsure, drill a pilot hole and use a coat hanger to check for obstructions — you’ll feel insulation if it’s clear.

Step 2: Know Your Sleeve Size

The Amana PBH092J12AA fits into the Amana wall sleeve model WS900A.

Dimensions are approximately 26" W x 15.5" H x 16" D.

Your opening should be slightly larger:

-

Width: 26 1/4"

-

Height: 15 3/4"

-

Depth: wall thickness + sleeve length

👉 See ASHRAE installation guidelines for wall unit mounting clearance standards.

3. The Tools You’ll Need

Before you cut anything, gather your gear.

Essential Tools:

-

Level and tape measure

-

Stud finder

-

Power drill with masonry bit

-

Circular saw (with fine-tooth blade)

-

Jigsaw (for finishing corners)

-

Screwdrivers

-

Caulking gun and weatherproof sealant

-

Insulation foam or backer rod

-

Exterior-grade silicone caulk

Optional (but smart):

-

Carpenter’s square

-

Utility knife

-

Safety glasses and gloves

-

Drop cloths

You’ll also need:

-

The Amana sleeve kit (WS900A)

-

Mounting brackets (if required)

-

Foam gasket kit (for vibration dampening)

4. Step-by-Step Installation

Alright — time to earn your DIY badge.

Step 1: Mark and Cut the Opening

-

Use your sleeve as a template. Trace the outline on the wall where you want the unit centered.

-

Double-check the height — aim for 12–18 inches above the floor.

-

Drill starter holes at each corner.

-

Use a reciprocating saw or jigsaw to cut out the interior wallboard.

-

Move outside and repeat the outline for the exterior cut.

Tony’s Tip:

Always cut slightly smaller than you think you need. You can expand the opening later, but patching drywall isn’t fun.

Step 2: Build the Wall Frame

The sleeve needs a solid, square frame to sit in. Use 2x4 lumber for the box frame inside the wall cavity.

-

Build a rectangular box that matches your sleeve’s outer dimensions.

-

Screw it into existing studs using deck screws.

-

Make sure it’s level and square — use a carpenter’s square to confirm.

A good frame prevents vibration and extends your unit’s life by keeping it snug and supported.

Step 3: Insert the Sleeve

Slide the wall sleeve (WS900A) into your framed opening from the outside.

Ensure it tilts slightly downward (¼ inch) toward the exterior for drainage.

Use foam gaskets or weatherstrip tape around the sleeve edges to cushion it and prevent air leakage.

Drill pilot holes through the sleeve’s mounting flanges and secure it with stainless steel screws.

Tony’s Tip:

Do not seal the bottom of the sleeve. Water should drain freely out of the back — block it, and you’ll create a birdbath in your wall.

Step 4: Seal and Insulate

-

Apply expanding foam or backer rod around gaps between the sleeve and framing.

-

Smooth it, then apply silicone caulk on both interior and exterior edges.

-

On the outside, use a bead of exterior-grade sealant along the top and sides only.

👉 Check the U.S. Department of Energy’s air sealing guide for best practices on insulation and moisture barriers.

Step 5: Slide in the Unit

The Amana 9,000 BTU unit weighs roughly 100 lbs, so get a second set of hands.

Lift carefully and slide it into the sleeve until it locks into place.

Secure the front chassis with screws or side clips (depending on your model).

Ensure the power cord reaches the outlet without stretching or bending.

Plug it in — you’re almost there.

Step 6: Test and Level

Run the system in both cooling and heating modes for 10–15 minutes.

Check for:

-

Even airflow

-

Smooth compressor startup

-

Condensate is draining outside the sleeve.

If you hear rattling, remove the grille and re-level the chassis.

This is where most DIYers mess up — even a ¼-inch tilt can cause vibration and noise.

5. Fine-Tuning for Quiet and Efficient Operation

Even when installed perfectly, a few extra tweaks make a big difference.

Add Insulation Around the Sleeve

If your wall cavity is deep, fill gaps with fiberglass insulation (not spray foam near coils).

This reduces vibration and sound transfer.

Seal the Interior Trim

Use foam tape or a trim kit to cleanly finish the interior around the grille. It looks pro and prevents airflow leaks.

Check for Air Recirculation

If hot exhaust air blows back into the intake, you’ll lose efficiency fast.

Make sure outdoor airflow is clear — 6–12 inches minimum around the rear vents.

For more airflow optimization tips, check HVAC.com’s through-the-wall installation guide.

6. Electrical Safety and Code Considerations

Because this Amana runs on a 115V circuit, you don’t need a dedicated 230V line — but you do need safe wiring.

My setup:

-

15A breaker

-

Dedicated line (nothing else on that circuit)

-

12-gauge wire to the outlet

If your home’s wiring is older than 1980, have an electrician verify the load capacity.

Don’t use an extension cord — it’s a fire hazard and voids the warranty.

👉 Read Energy Star’s electrical safety recommendations for small appliance circuits.

7. Finishing Touches: Make It Look and Run Like a Pro Install

You’ve done the hard work. Now let’s make it seamless.

-

Install the Amana grille and trim pieces.

-

Touch up drywall or siding as needed.

-

Wipe down the coil fins with a soft brush.

-

Run the system again to confirm the temperature difference between intake and exhaust — it should be 15–20°F in cooling mode.

That delta means your refrigerant charge and compressor are healthy.

8. Maintenance Routine After Installation

You’re not done after mounting.

A wall unit is like a car — simple upkeep keeps it running at peak performance.

Monthly:

-

Clean the filter (washable, reusable)

-

Check airflow and thermostat response.

Quarterly:

-

Inspect coil fins and drain path.

-

Verify the sleeve remains sealed and dry

Annually:

-

Spray coil cleaner (approved for aluminum fins)

-

Inspect weatherstripping and wall insulation.

-

Test heating mode for winter use

👉 For detailed care routines, refer to Amana’s maintenance guidelines.

9. Common Mistakes to Avoid

Here’s a list I’ve seen too many times:

-

No sleeve slope – traps water, ruins drywall.

-

Poor sealing leads to mold, drafts, and noise.

-

Overtightening screws – bends the frame, causes rattles.

-

Blocking drainage holes – always keep them open.

-

Ignoring electrical load – verify breaker and wiring before you start.

Follow this checklist, and your Amana system will hum quietly for a decade — no callbacks, no regrets.

10. Tony’s Pro Tricks for Perfect Performance

-

Use soundproofing foam inside wall cavities if your room echoes — it cuts vibration.

-

Add a drip edge above the outdoor vent if your wall sees heavy rain.

-

Paint the sleeve flange to match siding — it’s a small touch that looks custom.

-

Install a smart plug with scheduling to automate comfort and save power.

-

Monitor humidity — use “Dry Mode” in summer for less strain and lower bills.

11. Cost Breakdown: How Much You’ll Actually Spend

You’ll save serious money doing this yourself.

| Item | Cost | Notes |

|---|---|---|

| Amana PBH092J12AA | ~$950 | Heat pump + AC combo |

| Wall sleeve (WS900A) | ~$110 | Required for proper fit |

| Insulation/foam/caulk | ~$25 | Basic materials |

| Electrical outlet/surge protector | ~$30 | Optional but recommended |

| Tools/supplies | $0–50 | If you already own them |

| Labor (DIY) | Free | Sweat equity only |

Total DIY cost: ≈ $1,100

Pro installation cost: ≈ $2,000–$2,400

You save a solid $900–$1,300 — enough for a nice weekend getaway (or a stack of steaks and a new tool set).

12. Final System Test

Once everything’s sealed, wired, and leveled:

-

Run the system on cooling for 15 minutes.

-

Measure temp at intake and output — should be 15–20°F difference.

-

Switch to Heat Pump Mode for 10 minutes.

-

Confirm smooth cycling and quiet compressor operation.

-

Check the outdoor drain — steady drip, no pooling.

If all checks out, congratulations — you’re now officially your own HVAC installer.

13. Tony’s Final Word

If there’s one thing I’ve learned, people overcomplicate HVAC.

Installing a through-the-wall system like the Amana 9,000 BTU 115V isn’t a gamble — it’s a game of prep, patience, and precision.

Once it’s in, you’ve got a permanent comfort solution — no clunky window units, no seasonal swaps, no contractors charging “diagnostic fees.”

This Amana model gives you cooling, heating, and peace of mind, all powered by one outlet and one weekend of work.

So grab your level, measure twice, and make that first cut.

You’ll be surprised by what you can build — and even more surprised at how good 70°F feels when you did it yourself.

Next, let's get to know about the maintenance in the next blog.