🏡 Introduction: “Durability Isn’t Luck — It’s Designed In.”

Most homeowners think durability is something that “just happens” if you buy the right furnace, AC, or heat pump. But Samantha has seen too many good systems fail long before their time.

She’s walked into homes with:

-

rusted heat exchangers at year 7

-

blower motors screaming by year 5

-

condensate lines overflowing every summer

-

drain pans cracked in half

-

ductboard collapsing

-

coil fins matted with dust

-

control boards fried from moisture

Not because the equipment was bad.

Not because the homeowner neglected it.

But because the design choices made on installation day set the system up for a decade of trouble.

Samantha always says:

“Durability isn’t a feature you buy. It’s a feature you design.”

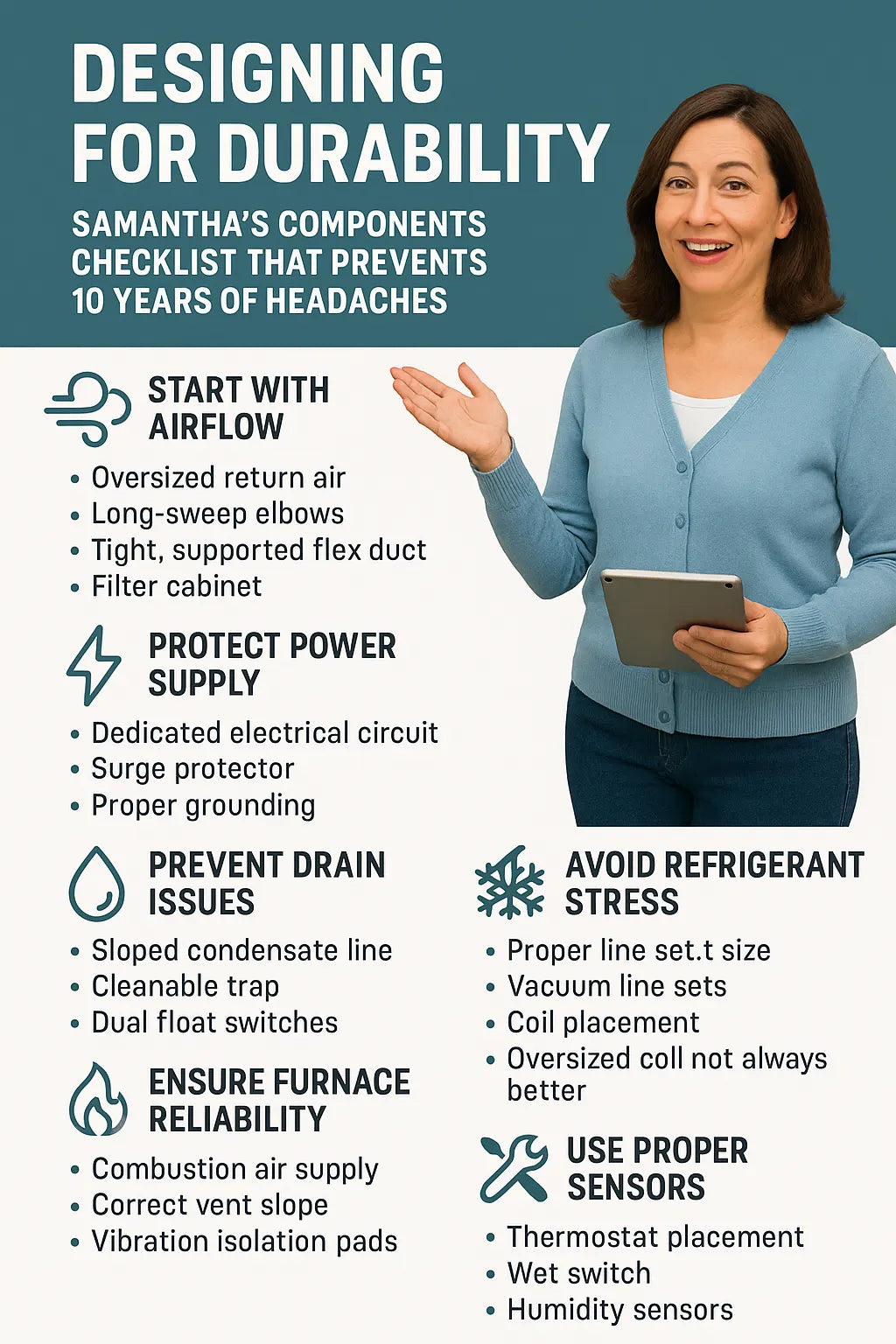

Today, she walks you through her Components-for-Durability Checklist — a list she uses on every system she reviews, whether it’s a simple furnace replacement or a full HVAC upgrade.

80,000 BTU 96% AFUE Upflow/Horizontal Two Stage Goodman Gas Furnace - GR9T960804CN

This checklist is how she prevents:

-

breakdowns

-

warranty fights

-

expensive repairs

-

early system death

-

hidden safety risks

-

moisture disasters

…for ten full years or more.

Let’s walk through the home with her — the way she teaches homeowners to think long-term, the way pros wish every system were installed.

🔧 1. The Foundation of Durability: “Start with Airflow or Everything Fails Early”

Icon: 💨

Samantha always starts here because poor airflow is the leading cause of:

-

overheated furnaces

-

cracked heat exchangers

-

burned-out ECM blowers

-

frozen AC coils

-

systems that short-cycle themselves to death

ENERGY STAR confirms that restricted airflow shortens system lifespan dramatically

So Samantha’s first durability component has nothing to do with equipment.

It’s the duct system.

💨 A. Oversized Return Air — Samantha’s #1 Durability Rule

Most returns are too small.

A furnace gasps for air. The blower struggles. Static pressure rises.

Samantha puts it simply:

“If your system can’t breathe, it will age 2–3 times faster.”

✔ What durable design requires:

-

return trunk sized for future ECM blowers

-

return filters at least 4–5 inches thick

-

multiple returns per floor

-

straight return paths with minimal elbows

💨 B. Long-Sweep Elbows Instead of 90° Turns

Sharp turns act like speed bumps inside ducts.

Over years, the blower compensates by working harder — burning out early.

ASHRAE confirms long-radius elbows reduce system resistance significantly:

🔗 https://www.ashrae.org/

✔ Samantha’s rule:

-

No more than 1–2 hard 90° elbows on supply trunk

-

Prefer long-sweep metal elbows on all major bends

💨 C. Flex Duct Pulled Tight and Supported Properly

Sagging flex duct kills airflow.

Bad airflow kills equipment.

✔ Samantha’s rule:

-

stretch flex duct tight like a guitar string

-

support every 4 feet

-

avoid sharp kinks

💨 D. Filter Cabinet Instead of Filter Grilles

Filter grilles restrict airflow.

Filter cabinets enhance it.

Long-term difference?

Five-to-ten years of blower survival.

🔌 2. Electrical Durability: “A System Is Only as Stable as the Power Feeding It”

Icon: ⚡

Electrical stress is one of the top causes of early failure in:

-

contactors

-

control boards

-

capacitors

-

ECM motors

-

compressors

Samantha insists on designing power stability into the install.

⚡ A. Dedicated Electrical Circuit & Proper Breaker Size

Too many homes have mislabeled or undersized breakers.

That’s a recipe for nuisance trips — or, worse, board failures.

✔ Samantha’s rule:

-

Verify wire gauge

-

Match breaker to manufacturer’s spec

-

No shared circuits

⚡ B. Surge Protection (Mandatory for Durability)

One power surge can destroy:

-

heat pump inverters

-

ECM blower motors

-

thermostats

-

control boards

These surges often aren’t noticed until days later.

✔ Samantha’s recommendation:

Install whole-house surge protection.

DOE confirms surges are a major cause of premature electronic failure

⚡ C. Proper Grounding & Bonding

Improper grounding can slowly corrode furnace cabinets, deteriorate drain pans, and cause unpredictable lockouts.

✔ Samantha’s rule:

Technician verifies continuity and grounding during install.

💧 3. Drainage & Moisture Durability: “Water Is the Enemy of Every Mechanical Room.”

Icon: 💧

Condensate-related failures are among the most expensive and destructive.

Samantha calls moisture:

“The silent system killer.”

She looks for weaknesses that might not show up until year 2… then destroy equipment by year 7 or 8.

💧 A. Properly Sloped Condensate Lines (Not Optional)

Poor slope leads to:

-

algae clogs

-

water backups

-

secondary drain pan overflows

-

mold inside furnace cabinet

✔ Samantha’s rule:

¼" drop per foot — no exceptions.

💧 B. A Cleanable Trap with Access Ports

Many systems have glue-and-forget traps.

A trap that can’t be cleaned becomes a future leak.

✔ Samantha’s rule:

Install a U-trap with removable caps and an air-tight cleanout.

💧 C. A Float Switch on the Primary Pan AND Secondary Pan

One switch is not enough.

Because one failure equals water in:

-

ceilings

-

walls

-

furnace compartments

✔ Samantha’s rule:

Dual float switches.

💧 D. Insulated Condensate Lines in Unconditioned Spaces

Sweating lines = rot, mold, damage, and corrosion.

DOE recommends insulation to prevent moisture condensation

🧊 4. Coil, Refrigerant & AC-Side Durability

Samantha knows that AC durability is mostly about preventing stress on the refrigerant circuit and coil.

❄️ A. Oversized Line Set Not Always Better — Must Match Manufacturer

Incorrect line-set sizing causes:

-

compressor strain

-

poor oil return

-

loud operation

-

premature compressor burnout

✔ Samantha’s rule:

Always follow manufacturer spec to the fraction.

❄️ B. Proper Vacuum & Moisture Removal at Installation

Moisture in the refrigerant line causes acid formation, which slowly destroys compressors.

✔ Samantha’s rule:

-

pull vacuum to 500 microns

-

verify hold test

-

require digital micron gauge

❄️ C. Coil Protection from Dust & Heat

Coils fail prematurely when:

-

placed too close to attic heat

-

exposed to return-leak dust

-

installed above uninsulated garage ceilings

✔ Samantha’s rule:

Place coil in cool, clean, low-dust conditions.

🔥 5. Furnace Durability Checkpoints

Samantha knows furnaces don’t usually “die” — they get worn down slowly by poor design.

🔥 A. Proper Combustion Air Supply

Insufficient combustion air leads to:

-

rollout switch trips

-

soot buildup

-

low flame quality

-

heat exchanger stress

ENERGY STAR addresses safe combustion in furnaces

🔥 B. Correct Vent Slope & Length

For 90%+ furnaces, improper vent slope causes condensate to:

-

puddle in the wrong place

-

freeze

-

corrode vent fittings

-

damage combustion chamber

🔥 C. Vibration Isolation Pads

Prevents:

-

cabinet rattling

-

blower bearings wearing out early

-

homeowner noise complaints

Samantha never installs a furnace directly on wood or metal without vibration damping.

🔥 D. Accessible Filter Location

Furnace filters that are difficult to reach → forgotten → airflow failure → furnace stress.

Durability depends on homeowner compliance.

🧱 6. Cabinet, Platform & Mechanical Space Durability

Icon: 🧱

Where a system lives determines how long it lives.

Samantha inspects:

-

attic heat

-

garage cold

-

closet size

-

platform insulation

-

access for service

DOE reinforces the importance of proper installation environment:

🔗 https://www.energy.gov/energysaver/home-heating-systems/furnaces-and-boilers

🧱 A. Minimum 30" Service Clearance

Without space to service the system → technicians break components to reach them.

🧱 B. Insulated Platform and Acoustic Padding

Reduces:

-

vibration

-

premature metal fatigue

-

blower motor strain

🧱 C. Mechanical Room Airflow Supply

Mechanical rooms need airflow.

Samantha checks:

-

door vents

-

louver size

-

placement

🛠️ 7. Controls, Sensors & Longevity Electronics

Icon: 🛠️

Modern HVAC systems rely on electronics more than ever.

Samantha ensures every electronic component is protected for long-term survival.

🛠️ A. Properly Placed Thermostat (Not on Wrong Walls)

Incorrect thermostat placement leads to:

-

short cycling

-

long cycling

-

overheating

-

coil freeze

-

furnace stress

Correct placement ensures balanced duty cycles.

🛠️ B. Wet-Switch Protection (Moisture Sensors)

Must be added in:

-

attics

-

closets

-

basements

A $30 part prevents $3,000 in water damage.

🛠️ C. Humidity Sensors & Auto-Dehumidification Control

High humidity ages:

-

blower motors

-

control boards

-

ducts

🪜 8. Samantha’s 10-Year Durability Checklist (Homeowner Version)

(Your system should include ALL of the following)

🟩 Essential Components

-

oversized return air

-

long-sweep elbows

-

media filter cabinet

-

properly sloped condensate line

-

cleanable trap

-

dual float switches

-

insulated condensate lines

🟩 System Protection

-

whole-house surge protection

-

correct breaker size

-

proper grounding

-

correct refrigerant line sizing

-

verified 500-micron vacuum

🟩 Mechanical Room Quality

-

30" minimum clearance

-

sealed platforms

-

insulated platforms

🟩 Comfort & Durability Controls

-

correct thermostat placement

-

humidity monitoring

-

wet-switch protection

🌟 Conclusion: “Durability Isn’t About the Furnace — It’s About Every Component Around It.”

Samantha teaches homeowners that durable HVAC systems aren’t expensive — they’re intentional.

Your furnace or AC doesn’t determine whether it lasts 10 years or 20.

Your design choices do.

She always ends her durability walk-through by reminding homeowners:

“Any system can last 20 years when the layout, components, protection and airflow set it up for success.”

Equipment doesn’t guarantee durability.

Design does.

Buy this on Amazon at: https://amzn.to/4hJt23t

In the next topic we will know more about: Quiet-by-Design Homes: Samantha’s Noise-Control Framework for Modern Furnace Layouts