When people talk about HVAC installation, condenser placement is often treated as an afterthought: “Set it outside, hook it up, done.”

In reality, how and where your outdoor condenser is mounted affects noise, efficiency, longevity, serviceability, and even warranty coverage.

I’ve seen brand-new systems fail early—not because of the equipment, but because the unit was sitting on an unstable, poorly chosen, or code-questionable base.

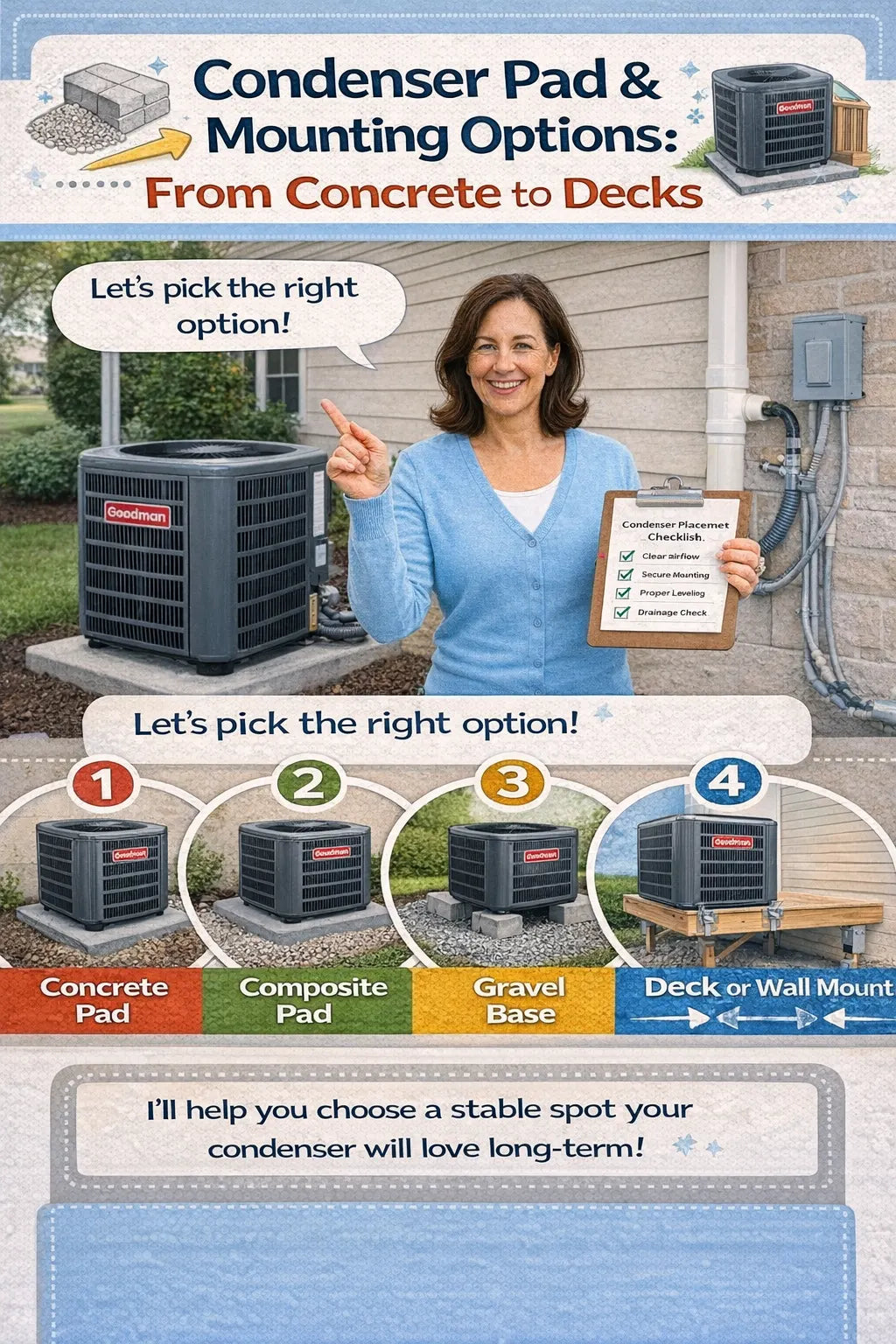

This guide walks you through every major condenser pad and mounting option, explains when each one makes sense, and helps you avoid the mistakes that quietly shorten system life.

🧠 Why the Condenser Base Matters More Than You Think

Your outdoor condenser:

-

weighs 150–350+ lbs

-

vibrates continuously

-

contains sensitive electronics and compressors

-

must drain water and shed heat efficiently

-

sits outside year-round in sun, rain, snow, and wind

If the base shifts, settles, tilts, floods, or vibrates excessively, the system pays the price—often slowly, expensively, and just after warranties expire.

📍 Step 1: Choosing the Right Location Before Choosing the Pad

Before picking what to set the condenser on, decide where it belongs.

Key placement rules

-

Adequate airflow on all sides

-

Clearance from walls, fences, and overhangs

-

Away from dryer vents and combustion exhaust

-

Accessible for service and cleaning

-

Above known flood levels where possible

Most manufacturers specify minimum clearances and site restrictions that must be respected.

🔗 External reference (example manufacturer installation guidance):

https://iwae.com/media/manuals/goodman/glxs4b-installation.pdf

🧱 Option 1: Concrete Pads (The Traditional Standard)

What they are

Pre-cast concrete slabs or poured-in-place pads placed directly on prepared ground.

Pros

-

Very stable when properly installed

-

Long lifespan

-

Resistant to UV and impact

-

Commonly accepted by inspectors

Cons

-

Heavy and harder to level

-

Can crack or sink if base prep is poor

-

Cold transfer can increase vibration in winter

Best practices for concrete pads

-

Compact the soil underneath

-

Use a gravel base for drainage

-

Ensure pad is perfectly level

-

Slight elevation above grade to prevent pooling

Concrete works best when soil conditions are stable and drainage is good.

🧱 Option 2: Composite / Polymer Condenser Pads

What they are

Lightweight, molded pads made from recycled composite materials.

Pros

-

Easier to transport and level

-

Won’t crack like concrete

-

Resistant to moisture and rot

-

Excellent vibration dampening

Cons

-

Lower weight can mean movement if base prep is poor

-

Must be properly supported to avoid flexing

-

Some cheaper pads warp under heat

When composite pads shine

-

Retrofit installations

-

Tight access areas

-

Noise-sensitive locations

-

Regions with freeze-thaw cycles

Many installers prefer these today—when installed on a well-prepared base.

🪨 Option 3: Gravel Base Systems

What they are

Condensers set on pads or blocks supported by compacted gravel beds.

Pros

-

Excellent drainage

-

Reduces frost heave

-

Affordable

-

Adjustable over time

Cons

-

Requires careful compaction

-

Can settle unevenly if rushed

-

Not always code-preferred alone

Best uses

-

Cold climates

-

Areas with heavy rainfall

-

Homes with known soil movement

Gravel isn’t “cheap”—it’s forgiving, when done correctly.

🪵 Option 4: Deck-Mounted Condensers

Why people consider this

-

Limited yard space

-

Walk-out decks or elevated homes

-

Flood-prone areas

Major considerations

-

Structural load capacity

-

Vibration transfer into living spaces

-

Noise amplification

-

Manufacturer approval (not all units allow this)

Must-have requirements

-

Engineer-approved load rating

-

Vibration isolation mounts

-

Adequate airflow clearance

-

Compliance with local code

Deck mounting is possible—but never casual.

🧗 Option 5: Wall Brackets & Elevated Mounts

Common in:

-

Coastal regions

-

Snow-heavy climates

-

Urban or multi-family buildings

Pros

-

Keeps unit above snow and flood water

-

Frees ground space

-

Reduces debris exposure

Cons

-

Requires solid structural anchoring

-

Can transmit vibration into walls

-

Higher installation cost

Key safety checks

-

Anchored into structural framing (not siding)

-

Rated brackets for condenser weight

-

Proper vibration isolation

🔗 External reference (wind & elevation considerations):

https://www.fema.gov/emergency-managers/risk-management/building-science

🌧️ Drainage & Moisture Management (Every Mount Type)

Regardless of pad type, condensers must manage water correctly.

Watch for:

-

standing water under the unit

-

mud splash onto coils

-

ice buildup in winter

-

blocked coil airflow from debris

Smart solutions

-

elevate slightly above grade

-

slope surrounding soil away

-

maintain vegetation clearance

-

install snow diverters if needed

Water problems rarely show up immediately—but they always show up eventually.

🔊 Vibration & Noise Control (Often Overlooked)

A stable pad isn’t always a quiet pad.

Noise-reduction strategies

-

rubber isolation feet

-

composite pads with damping properties

-

avoiding direct contact with structures

-

proper refrigerant line support

Noise complaints are one of the top reasons homeowners regret condenser placement.

🧯 Code, Clearance & Inspection Considerations

Inspectors typically check:

-

proper mounting and stability

-

required clearances

-

electrical disconnect access

-

protection from physical damage

Local codes may restrict:

-

deck mounting

-

roof mounting

-

proximity to property lines

🔗 External reference (mechanical code overview)

🚩 Common Pad & Mounting Mistakes to Avoid

-

Setting pads directly on bare soil

-

Ignoring slope and drainage

-

Mounting too close to walls or fences

-

Allowing units to tilt even slightly

-

Placing condensers where snow or debris accumulates

-

Sharing pads with other equipment

These mistakes don’t usually cause instant failure—they cause early failure.

🧡 Samantha’s Final Advice

A condenser doesn’t just need to sit somewhere—it needs a stable, level, well-drained, code-compliant home of its own.

If you remember one thing, remember this:

The best condenser pad is the one that matches your climate, soil, structure, and noise tolerance—not just what’s cheapest or fastest.

Buy this on Amazon at: https://amzn.to/43doyfq

In the next topic we will know more about: Ductwork Integration: Tips for Seamless Airflow with Your Goodman System