🌿 Introduction: The Part of Your HVAC System No One Talks About — But Should

Your air conditioner or high-efficiency gas furnace is quietly producing gallons of water per day — sometimes dozens in humid climates. This water, called condensate, is one of the least understood parts of HVAC design.

Most homeowners never see it. Most installers barely think about it. But Savvy?

She knows condensate carries:

-

Acidity

-

Heat

-

Microbial potential

-

Energy signatures

-

Environmental impact

When condensate is ignored, homes flood, pumps fail, basements grow mold, and furnaces corrode.

When it’s designed intelligently, systems last longer and operate sustainably.

This is the eco-engineering of “the forgotten flow.”

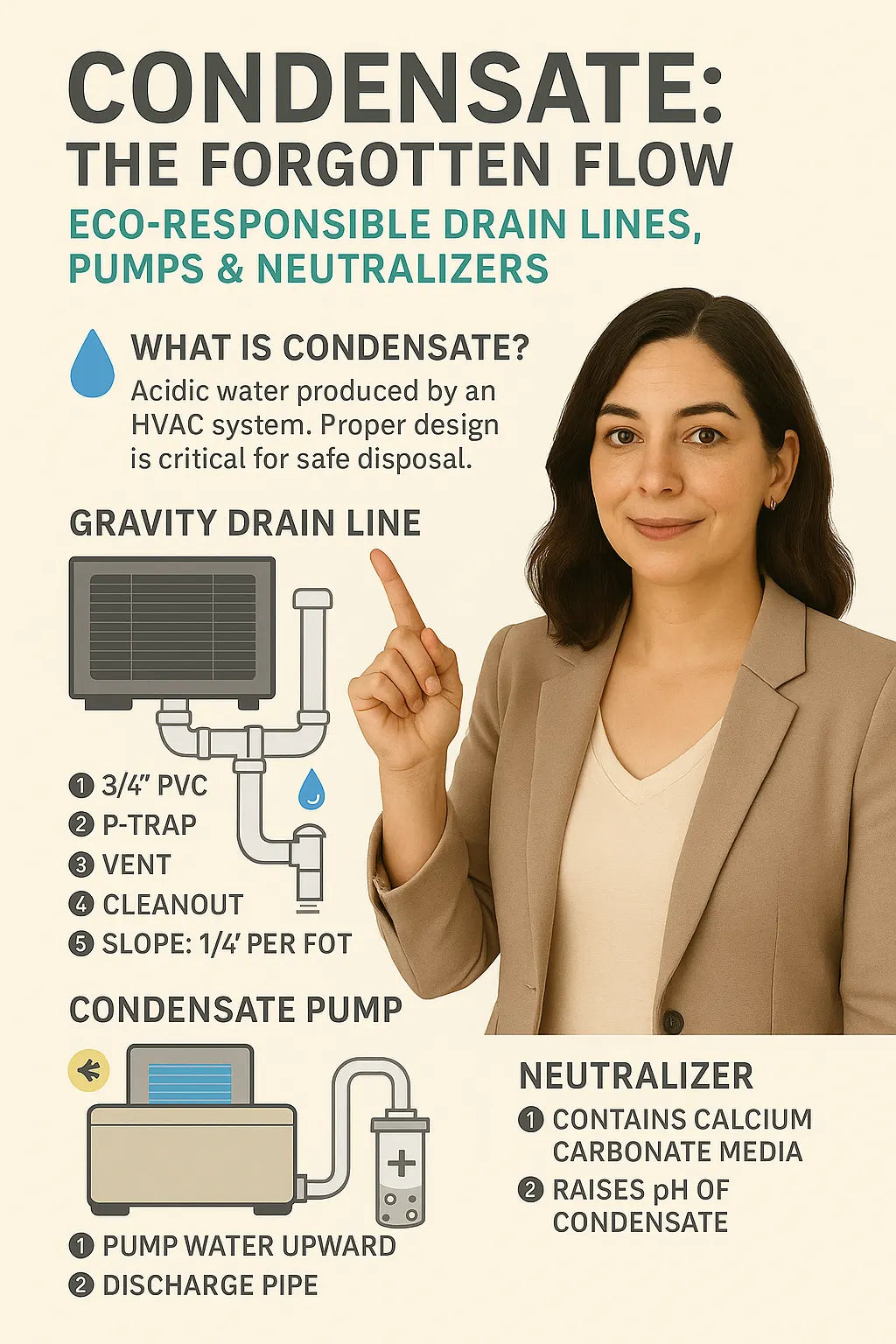

💧 1. What Is Condensate — And Why Does It Matter?

Icon: 💦

Condensate forms whenever warm, moist air hits a cold cooling coil (AC mode) or when a high-efficiency furnace extracts latent heat from its exhaust stream.

Two Systems Produce Condensate:

-

Air Conditioners / Heat Pumps

-

Moist air condenses on the evaporator coil

-

Produces neutral pH water

-

-

96%+ AFUE Gas Furnaces

-

Flue gases cool below dew point

-

Condensate becomes acidic (pH ~3–5)

-

Contains carbonic acid + residual combustion byproducts

-

Neutral water is easy to manage.

Acidic water requires eco-responsible treatment.

Condensate is the HVAC system’s silent storyteller — it reveals airflow, coil performance, humidity load, and system health.

🧠 2. The Physics of Condensate Flow — Why Gravity Isn’t Optional

Icon: 🌐

Condensate isn’t under pressure.

It depends entirely on:

-

Gravity

-

Slope

-

Trap design

-

Line diameter

-

Airflow pressure zones

If any one of these is wrong, flow stops.

Savvy’s Condensate Physics:

-

Water follows the path of least resistance

→ Usually into your emergency pan if poorly designed -

Negative pressure at the coil requires a trap

→ Otherwise air gets sucked into the drain, stalling flow -

Small air bubbles restrict water movement

→ Causing backups and microbial buildup -

Horizontal runs need slope

→ ¼” per foot minimum -

Condensate lines must never rely on flat runs

→ Stagnant water = mold + biological slime

Condensate flow is a science.

Treat it like plumbing, not an afterthought.

🛠️ 3. Designing the Perfect Gravity Drain Line (AC Systems)

Icon: 📏

Most AC condensate lines fail because they’re installed too casually.

Here is the Savvy-approved drain design:

✔️ 1. Use 3/4” PVC — Never 1/2”

½” clogs easily with algae and debris.

¾” PVC ensures reliable flow and low maintenance.

✔️ 2. Maintain ¼” Slope per Foot

Not optional.

Not “eyeballed.”

Use a level or laser.

✔️ 3. Install a P-Trap at the Coil

Why?

-

The coil is under negative pressure

-

Without a trap → system sucks air into the drain

-

Water will not flow

Trap must be:

-

At least 3” deep

-

Vented on the outlet side

✔️ 4. Include a Cleanout

A vertical cleanout with a removable cap allows:

-

Flushing

-

Vacuuming

-

Tablet insertion

Cleanouts prevent emergency service calls.

✔️ 5. Terminate Safely

Acceptable discharge points:

-

Condensate pump

-

Basement drain

-

Laundry drain

-

Outside (local code dependent)

-

Floor drain with air gap

Never connect directly to a sewer without an approved air gap.

⚠️ 4. Common Drain Line Mistakes (and Why They Cause Havoc)

Icon: ❌

Savvy’s top offenders:

❌ 1. No trap

Results in air lock → water backs up.

❌ 2. Trap installed after long horizontal run

Trap must be within 12 inches of the drain pan.

❌ 3. Slope too low

Water stagnates → sludge builds.

❌ 4. Oversized trap

If too deep, water never evacuates fully.

❌ 5. Wrong materials

Flexible vinyl tubing kinks and collapses.

❌ 6. Drain terminating onto mulch or soil

Leads to mold, moss, insects, and line blockage.

🔊 5. Condensate Pumps — When Gravity Isn’t an Option

Icon: ⚡

A condensate pump is needed when:

-

The air handler is in a basement without a floor drain

-

Drain must pump upward

-

The discharge point is distant

-

Furnace is far from a drain

How Condensate Pumps Work

-

Water enters the reservoir

-

Float switch rises

-

Pump activates and discharges water

-

Overflow safety switch shuts down system if pump fails

✔️ Savvy’s Rules for Pump Installation:

Rule 1: Always wire the safety overflow switch

This prevents catastrophic flooding.

Rule 2: Use 3/8” or 1/2” vinyl discharge tubing

But secure with clamps to avoid slips.

Rule 3: Trap is NOT needed before the pump

The pump reservoir is inherently open to the atmosphere.

Rule 4: Install check valves where needed

Prevents backflow into the reservoir.

Rule 5: Mount the pump on vibration pads

Reduces noise transfer into the home.

☣️ 6. Condensate Neutralizers — The Eco-Responsibility Step Everyone Forgets

Icon: 🌱

High-efficiency furnaces generate acidic condensate that can:

-

Corrode drains

-

Damage sewer piping

-

Harm soil

-

Poison groundwater

-

Eat through concrete

A neutralizer raises pH to ~6–8 before disposal.

✔️ What’s Inside a Condensate Neutralizer?

A tube or cartridge filled with:

-

Calcium carbonate

-

Magnesium oxide

-

Limestone media

Acid + alkaline = harmless water.

✔️ How to Size a Neutralizer

Depends on:

-

Furnace BTU capacity

-

Expected condensate volume

-

Run time

-

Media life expectancy

Typical 80k–120k BTU furnaces require annually serviced media.

✔️ Maintenance Rules

-

Replace media every 6–12 months

-

Check for channeling (water bypassing media)

-

Verify pH at outlet (test strips)

-

Keep horizontal orientation when required

Neutralizers are not optional for eco-friendly homes — they’re essential.

🦠 7. Microbial Growth — The Hidden Battle Inside the Drain System

Icon: 🧫

Warm, wet, dark drain lines attract:

-

Biofilm

-

Algae

-

Bacteria

-

Fungal colonies

-

Slime

These cause:

-

Odors

-

Slow drainage

-

Air handler overflow

-

Indoor air quality issues

✔️ Prevention Techniques

1. Install Clear-Service Traps

Transparent PVC traps show blockages early.

2. Use condensate tablets

Safe, non-acidic tablets reduce biofilm.

3. Flush with warm water twice per season

Never bleach — it degrades PVC and can backflow vapors.

4. Ensure proper slope

Stagnant water = microbial paradise.

🧪 8. Venting the Condensate Line — The Most Misunderstood Step

Icon: 🌬️

Drain lines must allow air to enter behind flowing water.

Venting Rules:

-

Install vent on the outlet side of the trap

-

Vent height: 2–4” above trap

-

Never cap a vent

-

Use a tee fitting for smooth airflow

A ventless line will gurgle, struggle, and back up.

🏡 9. Outdoor Termination — When Dumping Condensate Outside Is Good or Bad

Icon: 🌤️

✔️ Good Outdoor Discharge Situations:

-

AC condensate only

-

Non-freezing climates

-

Areas with good drainage

✔️ Not Recommended:

-

Acidic furnace condensate

-

Freezing zones (line freezes → system shuts down)

-

Areas prone to insects or vegetation overgrowth

Outdoor Drain Tips:

-

Terminate 6–12” above grade

-

Avoid splashing against siding

-

Use splash blocks where needed

🧭 10. Condensate Routing — Clean, Efficient, Future-Proof

Icon: 🗺️

A perfect routing plan is:

-

Short

-

Straight

-

Sloped

-

Accessible

-

Supported

-

Code-compliant

Savvy’s Routing Rules:

-

Keep horizontal runs < 10 feet when possible

-

Support every 4–5 feet

-

Avoid high spots

-

Use sweeping 90° fittings, not hard elbows

-

Label the line for future service techs

🔍 11. Diagnosing Condensate Problems — The 15-Minute Checklist

Icon: 🧠

Ask:

-

Is the trap full right after startup?

-

Is water flowing freely?

-

Is suction pulling air through the drain?

-

Are there gurgling sounds?

-

Is the pump cycling normally?

-

Is there water in the emergency pan?

-

Is humidity rising indoors?

-

Does the furnace exhibit error codes?

Condensate failures often mimic refrigerant problems — diagnosis matters.

🌱 12. Sustainability Wins — Eco-Responsible Condensate Handling

Icon: 🌍

Sustainable condensate management:

-

Protects soil and waterways

-

Reduces sewer corrosion

-

Extends furnace life

-

Improves indoor air quality

-

Reduces flooding and water waste

-

Helps buildings last longer

Even water from an HVAC system carries an environmental footprint.

Savvy turns it into an eco-opportunity.

🔗 Final Verified Resources

-

EPA Indoor Air & Moisture Management

https://www.epa.gov/indoor-air-quality-iaq -

EnergyStar HVAC Installation Guidance

https://www.energystar.gov -

ASHRAE Condensation & Drainage Standards

https://www.ashrae.org -

ACCA HVAC System Design & Installation Resources

https://www.acca.org -

Building Science Corporation — Moisture & Drainage Best Practices

https://buildingscience.com

🌟 Closing: Condensate Isn’t Just Water — It’s the Eco Pulse of Your System

Ignore condensate, and your HVAC system becomes vulnerable.

Engineer it intelligently, and your entire home becomes more resilient.

Smart condensate design means:

-

No backups

-

No mold

-

No acidic corrosion

-

No pump failures

-

No emergency overflows

But more importantly —

it means your home breathes cleanly, safely, and sustainably.

That’s the Savvy way to design “the forgotten flow.”

Buy this on Amazon at: https://amzn.to/4hyDyKH

In the next topic we will know more about: Balanced Air, Balanced Home — Designing Supply & Return Paths That Actually Match Your 3-Ton System