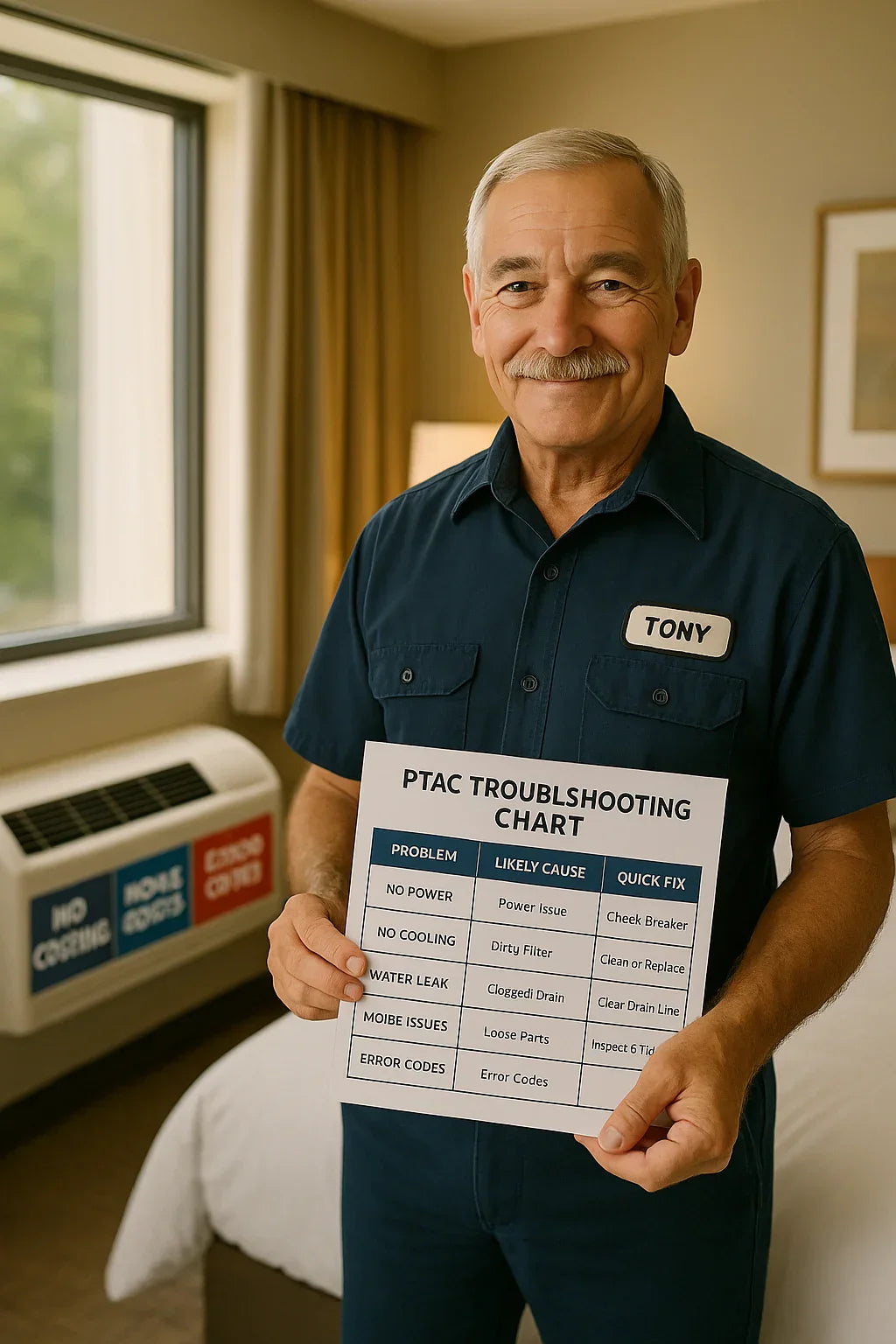

👋 Introduction: “Tony, My PTAC’s Acting Up — What Do I Do?”

Hey folks, Tony here.

Look — even the best PTAC units can hiccup from time to time. The good news is most PTAC problems are easy to diagnose if you know what to look for.

Today, I’ll walk you through the most common PTAC issues, troubleshooting steps, and when to call in a pro.

🔧 Quick PTAC Troubleshooting Chart

| Problem | Likely Cause | Quick Fix |

|---|---|---|

| Unit won’t turn on | Power issue | Check breaker, wall plug |

| Blowing warm air (when cooling) | Dirty filter, refrigerant low | Clean filter, call tech for refrigerant |

| Unit leaking water inside | Clogged drain | Clear drain line |

| Loud rattling noise | Loose blower or debris | Inspect fan assembly |

| Smells bad | Mold/mildew | Clean coils & drain pan |

| Display flashing error code | Fault diagnosis | Refer to error code guide |

🔗 Verified Source:

Friedrich PTAC Troubleshooting Guide

🚫 Problem 1: PTAC Won’t Turn On

✅ Step 1: Check Power Supply

-

Verify wall plug is secure.

-

Check circuit breaker or GFCI outlets.

-

Inspect power cord for damage.

✅ Step 2: Check Control Settings

-

Confirm unit isn’t locked via remote thermostat.

-

Look for tripped safety cut-offs.

💡 Tony’s Pro Tip:

"Nine out of ten 'dead PTAC' calls I get are a flipped breaker from a popped GFCI circuit."

❄ Problem 2: Not Cooling Properly

Possible Causes:

-

Dirty air filter blocking airflow.

-

Dirty evaporator coil.

-

Low refrigerant charge (leak).

-

Stuck reversing valve (on heat pump models).

Quick Fixes:

-

Clean filter (monthly).

-

Use coil cleaner spray.

-

If refrigerant is low — certified HVAC tech required.

🔗 Verified Source:

Amana PTAC Service Manual (2025 Models)

🔥 Problem 3: Not Heating Properly

Possible Causes:

-

Dirty filter reducing airflow.

-

Heat pump malfunction (low ambient temp).

-

Backup electric heat not engaging.

-

Faulty temperature sensors.

Quick Fixes:

-

Clean filters & coils.

-

Verify electric backup heat relay.

-

Check for tripped high limit switches.

💡 Tony’s Take:

"In cold climates, PTAC heat pumps may struggle below freezing — that’s when backup electric heat needs to kick in."

💧 Problem 4: Water Leaking Inside the Room

Causes:

-

Clogged condensate drain.

-

Improper sleeve slope (should drain outside).

-

Dirty evaporator coil causing freeze-ups.

Quick Fixes:

-

Clear drain line with flexible brush.

-

Verify sleeve angle.

-

Inspect for frozen coil buildup.

🔗 Verified Source:

ASHRAE Moisture Control Guide for PTAC Units

🔊 Problem 5: Excessive Noise or Vibration

| Noise Type | Common Cause | Solution |

|---|---|---|

| Rattling | Loose blower fan | Tighten fasteners |

| Buzzing | Electrical relay issue | Check contactors |

| Whistling | Air leaks around sleeve | Seal gaps properly |

| Grinding | Failing motor bearings | Replace blower motor |

💡 Tony’s Rule:

"The louder your PTAC gets, the more money you save catching it early."

🦠 Problem 6: Bad Odors

Causes:

-

Mold or mildew buildup inside drain pan.

-

Dirty evaporator coil.

-

Bacterial growth on moist surfaces.

Solutions:

-

Clean coils quarterly.

-

Use antimicrobial coil treatments.

-

Clean drain pan regularly.

🔗 Verified Source:

National Air Duct Cleaners Association - PTAC Odor Control

🖥 Problem 7: Flashing Error Codes

Most PTAC units display fault codes to help with diagnostics.

| Error Code | Meaning | Action |

|---|---|---|

| E1 | Indoor temp sensor fault | Replace sensor |

| E2 | Outdoor temp sensor fault | Check wiring |

| E3 | Freeze protection activated | Clear airflow blockages |

| E4 | Overheating | Clean filters & coils |

👉 Always check your model’s specific code list.

🔗 Verified Source:

GE Zoneline PTAC Fault Code Reference (2025)

📉 When to Repair vs. Replace

| Issue | Repair Cost | Replace If… |

|---|---|---|

| Filter, coil cleaning | <$100 | Never |

| Blower motor | $200–$400 | Unit is >10 years old |

| Compressor failure | $800–$1,200 | Unit is >8 years old |

| Repeated refrigerant leaks | $$$ | Replace |

💡 Tony’s Pro Tip:

"When repair costs hit 50% of replacement cost — I tell my clients to pull the trigger on new equipment."

🔚 Conclusion: PTAC Troubleshooting Isn’t Rocket Science

✅ Keep filters clean

✅ Clean coils regularly

✅ Check drainage monthly

✅ Listen for odd noises

And when weird things happen? Use the error codes.

If you catch issues early, most PTAC problems stay cheap and easy.

As Tony always says:

"Take care of your PTAC, and it’ll take care of you — year-round comfort without breaking your wallet."

👉 Still my #1 pick for reliability:

Amana Distinctions 9000 BTU PTAC Heat Pump

In the next topic we will know more about: Wall Sleeves 101: Why They Matter for PTAC Performance and Noise Control