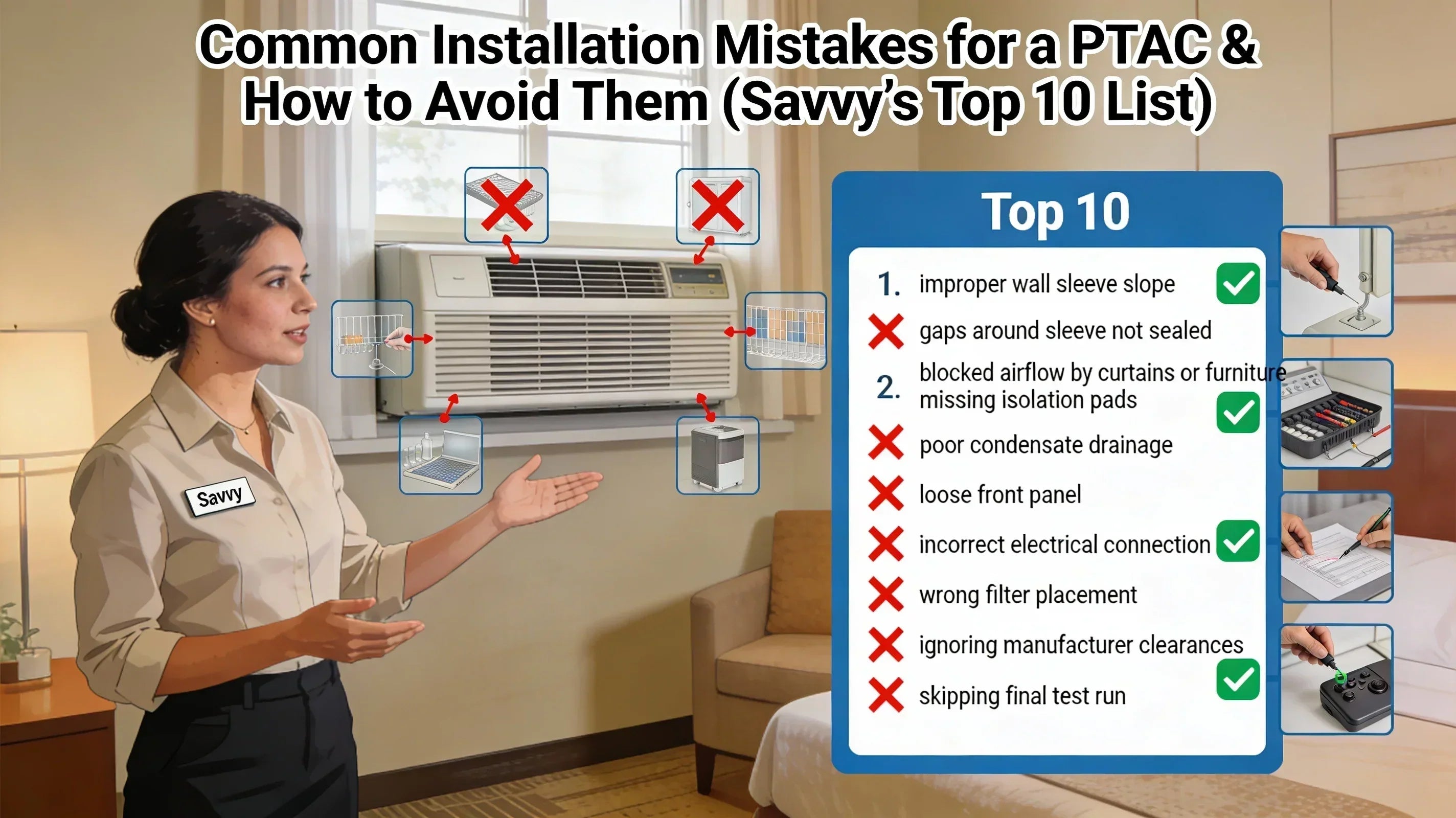

(Savvy’s Top 10 List for PTAC Installs That Actually Last) 🌿🧠

If I could sit every installer—DIY or pro—down for one conversation before a PTAC install, this would be it.

Because here’s the truth most manuals don’t say out loud:

PTACs don’t fail randomly. They fail predictably—because of the same installation mistakes, over and over again.

The good news?

Every single one of these mistakes is avoidable once you know what to look for.

This guide is Savvy’s Top 10 PTAC Installation Mistakes, why they cause problems, and exactly how to avoid them so your install feels quiet, efficient, and hotel-grade—not “temporary appliance energy.”

Amana J-Series PTAC Model 17,000 BTU PTAC Unit with 5 kW Electric Heat

🧠 Why Installation Mistakes Matter More Than Brand or BTUs

Most comfort complaints—noise, leaks, short cycling, high energy bills—get blamed on the unit.

In reality:

-

The equipment is usually fine

-

The install decisions are the problem

PTACs are sensitive systems:

-

They sit in walls

-

They handle moisture

-

They move a lot of air in tight spaces

-

They connect directly to building structure

That makes installation details non-negotiable.

❌ Mistake #1: Installing a Sleeve That Isn’t Pitched Correctly

Why it’s a problem:

A flat or inward-pitched sleeve traps condensate, leading to:

-

Interior leaks

-

Mold risk

-

Corrosion

-

Dripping noises

How to avoid it:

-

Sleeve must be level side-to-side

-

Sleeve must have a slight pitch outward

-

Verify pitch before the PTAC goes in

This is clearly called out in Amana’s installation guidance.

https://www.theacoutlet.com/documents/Installation-Guide-Amana-J-Series.pdf

📌 Savvy rule: If water can’t escape by gravity, it will escape creatively.

❌ Mistake #2: Using Foam as a Structural Fix

Why it’s a problem:

High-expansion foam can:

-

Warp the sleeve

-

Block drainage paths

-

Push the PTAC out of alignment

How to avoid it:

-

Support the sleeve mechanically

-

Use low-expansion foam only for air sealing

-

Never rely on foam to hold weight or correct framing errors

Foam is an air seal—not a substitute for carpentry.

❌ Mistake #3: Skipping the Dedicated Electrical Circuit

Why it’s a problem:

PTACs draw significant power, especially with electric heat. Shared circuits cause:

-

Breaker trips

-

Voltage drops

-

Control board stress

-

Premature component failure

How to avoid it:

-

Always use a dedicated 208/230V circuit (per nameplate)

-

Verify breaker size and wire gauge

-

Bring in an electrician if unsure

Electrical safety guidance:

https://www.cpsc.gov/safety-education/safety-guides/electrical

📌 Savvy mindset: Electricity is not a place to “make it work.”

❌ Mistake #4: Sliding the PTAC In Before the Site Is Ready

Why it’s a problem:

Once the unit is in, access is limited. Rushing leads to:

-

Missed sleeve issues

-

Poor alignment

-

Forgotten sealing steps

How to avoid it:

Before sliding the unit:

-

Sleeve installed, sealed, and pitched

-

Electrical ready

-

Drain strategy confirmed

-

Tools and fasteners staged

PTAC installs reward patience—not strength.

❌ Mistake #5: Over-Tightening Screws (Especially on the Chassis)

Why it’s a problem:

Over-tightening:

-

Transfers vibration

-

Warps metal

-

Creates buzzing and hum

How to avoid it:

-

Tighten screws snug, not cranked

-

Use only manufacturer-specified mounting points

-

Let isolation materials do their job

More force ≠ better install.

❌ Mistake #6: Ignoring Airflow Clearance Indoors or Outdoors

Why it’s a problem:

Restricted airflow causes:

-

Noise

-

Short cycling

-

Reduced efficiency

-

Compressor stress

How to avoid it:

-

Keep furniture away from discharge air

-

Ensure filters sit flat

-

Verify exterior grille clearance

Amana grille & airflow guidance:

https://www.amana-ptac.com/products/ptac-accessories/outdoor-grilles

💡 Savvy insight: Quiet airflow is aligned airflow.

❌ Mistake #7: Blocking Condensate Paths While Sealing

Why it’s a problem:

Over-sealing traps water, leading to:

-

Interior leaks

-

Hidden wall damage

-

Mold-friendly conditions

How to avoid it:

-

Seal air gaps—but never dam water

-

Keep sleeve bottom and drain paths clear

-

Understand where condensate exits

EPA moisture guidance:

https://www.epa.gov/mold/mold-course-chapter-2

📌 Savvy rule: Air sealing and water management must coexist.

❌ Mistake #8: Poor Thermostat Placement or Mismatch

Why it’s a problem:

Bad control strategy leads to:

-

Temperature swings

-

Excessive cycling

-

Higher energy use

How to avoid it:

-

Use PTAC-compatible thermostats

-

Place sensors away from drafts and direct discharge

-

Don’t overcomplicate controls

Thermostat best practices (DOE):

https://www.energy.gov/energysaver/thermostats

❌ Mistake #9: Treating Noise as “Normal”

Why it’s a problem:

Noise is feedback. Ignoring it allows:

-

Vibration damage

-

Loose components

-

Reduced comfort

How to avoid it:

-

Address rattles immediately

-

Use isolation materials

-

Test both cooling and heating modes before leaving

Quiet installs are achievable—and expected.

❌ Mistake #10: Skipping the Final System Check

Why it’s a problem:

Most problems show up in the first 10–15 minutes.

How to avoid it:

Before calling it done:

-

Run cooling

-

Run heating

-

Listen for noise

-

Check for leaks

-

Feel for drafts

That final check saves callbacks, frustration, and reputation.

✅ Savvy’s “No-Regrets” Installation Checklist

If you want to avoid all ten mistakes, confirm this before you leave:

-

☐ Sleeve pitched outward

-

☐ Dedicated electrical circuit

-

☐ PTAC aligned and secured

-

☐ Airflow unobstructed

-

☐ Drainage paths clear

-

☐ Thermostat placed correctly

-

☐ Unit runs quietly in all modes

If all boxes are checked—you’ve done it right.

🌿 Savvy’s Final Thought

PTAC installation isn’t about speed.

It’s about sequence, intention, and respect for physics.

Avoid these ten mistakes, and you’ll get:

-

Better comfort

-

Lower energy use

-

Fewer service calls

-

Longer equipment life

That’s not luck.

That’s craftsmanship.

Buy this on Amazon at: https://amzn.to/434DIng

In the next topic we will know more about: How to Capture Warranty Coverage During Installation (Without Voiding It)