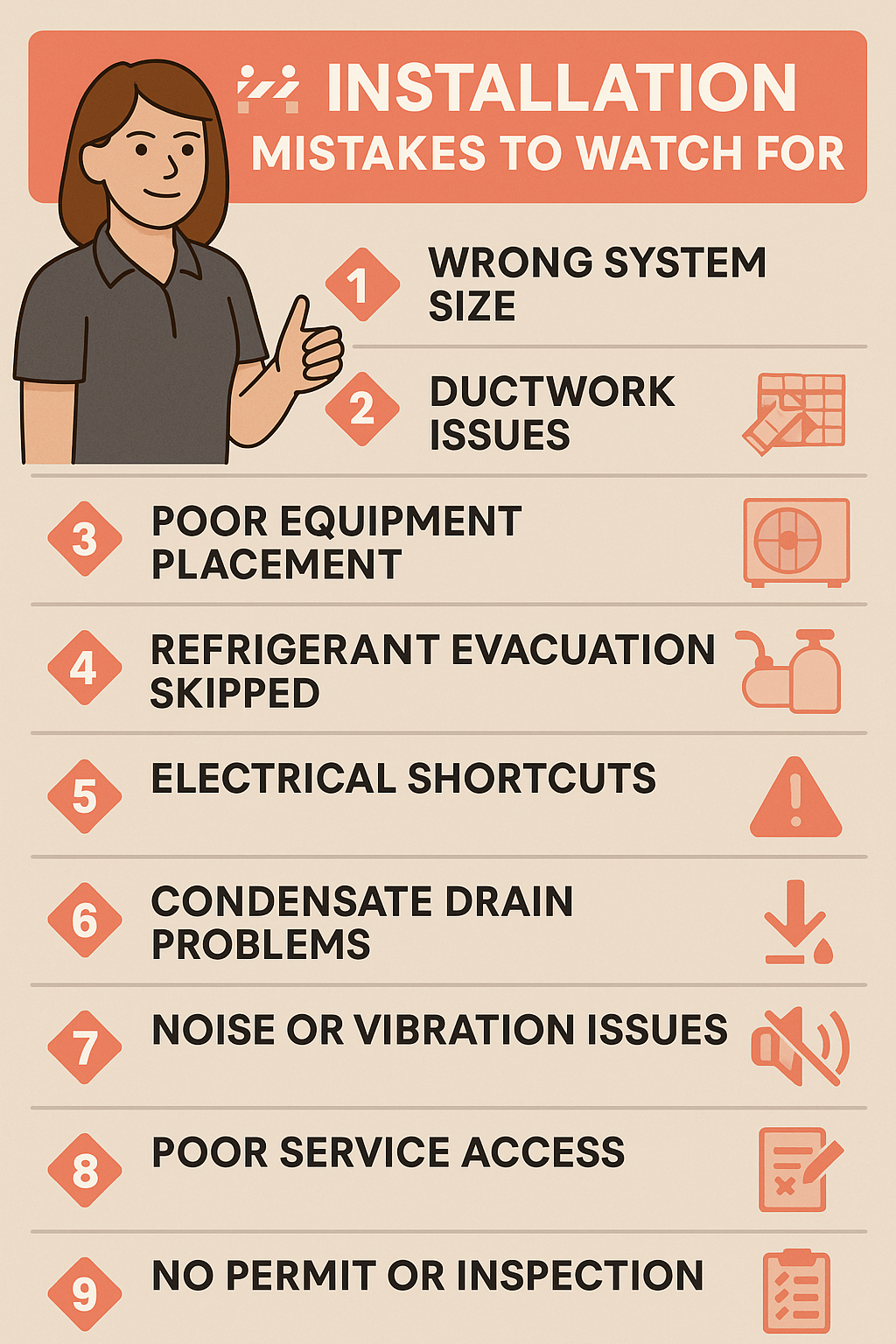

Samantha’s real-world guide to spotting problems early, asking better questions, and protecting your HVAC investment

After years of reviewing installs, listening to homeowner complaints, and tracing comfort problems back to their source, I’ve learned something important:

👉 Most HVAC failures don’t start as failures. They start as small installation errors that compound over time.

These mistakes rarely cause immediate breakdowns. Instead, they quietly reduce efficiency, increase noise, shorten equipment life, and create the “this system never quite felt right” experience so many homeowners describe.

This guide pulls together the most common HVAC installation errors I see in the field, explains why they matter, and—most importantly—shows you how to avoid them before they cost you comfort or money.

1️⃣ 📐 Wrong System Size (Oversized Is Still a Mistake)

What goes wrong

Installers size systems based on:

-

Square footage alone

-

The old system’s size

-

Rules of thumb

This often leads to oversized equipment, which:

-

Short-cycles (on/off too frequently)

-

Struggles with humidity

-

Wears out components faster

How to avoid it

-

Insist on a proper load calculation (Manual J)

-

Make sure recent home upgrades are considered

ACCA’s Manual J is the recognized standard for residential HVAC sizing.

Samantha takeaway: Bigger systems don’t mean better comfort—just bigger mistakes.

2️⃣ 🌬️ Ignoring Ductwork Limitations

What goes wrong

A new system is installed without checking whether existing ducts can actually handle the airflow.

Common results:

-

Weak airflow in some rooms

-

Noisy returns or whistling registers

-

Reduced system capacity

How to avoid it

-

Have duct sizing reviewed, especially for larger systems

-

Address obvious restrictions or leaks before installation

-

Ensure return air paths are adequate

The U.S. Department of Energy notes that duct leakage and poor airflow can significantly reduce system efficiency.

3️⃣ 🔧 Poor Equipment Placement (Inside or Outside)

What goes wrong

Equipment is placed where it fits, not where it works best:

-

Condensers jammed into tight corners

-

Air handlers installed with blocked service panels

-

Units placed in areas prone to flooding or noise complaints

Why it matters

-

Restricted airflow

-

Higher operating temperatures

-

Service headaches and higher repair costs

How to avoid it

-

Follow manufacturer clearance requirements

-

Plan for service access, drainage, and noise impact

Manufacturer installation manuals clearly define acceptable placement.

👉 https://www.goodmanmfg.com/resources

4️⃣ 🧪 Skipping Proper Refrigerant Evacuation

What goes wrong

This is one of the most damaging shortcuts:

-

No vacuum pump

-

No micron gauge

-

“Good enough” evacuation

Moisture and air left in the system:

-

Damage compressors

-

Reduce efficiency

-

Shorten system lifespan

How to avoid it

-

Confirm evacuation is performed and verified

-

Ask whether a micron gauge is used (not just gauges)

ACCA’s Quality Installation standards emphasize evacuation verification as essential.

👉 https://www.acca.org/standards

Samantha reality check: This mistake won’t show up on day one—but it will show up eventually.

5️⃣ ⚡ Electrical Shortcuts & Code Violations

What goes wrong

-

Incorrect breaker sizing

-

Poor grounding

-

Inaccessible disconnects

-

Messy or strained wiring

These errors can cause:

-

Nuisance breaker trips

-

Failed inspections

-

Safety hazards

How to avoid it

-

Ensure electrical work follows the National Electrical Code (NEC)

-

Verify disconnect placement and accessibility

The NEC exists to protect homeowners, not slow installers down.

👉 https://www.nfpa.org

6️⃣ 💧 Condensate Drain Mistakes (The Silent Destroyer)

What goes wrong

-

Improper drain slope

-

Missing traps

-

No secondary pan in attic installs

-

No float switch where damage risk exists

These issues often show up as:

-

Ceiling stains

-

Moldy smells

-

Warped floors

How to avoid it

-

Treat condensate management as a design step

-

Test drains before leaving the job

Water damage repairs almost always cost more than doing this right the first time.

7️⃣ 🔊 Noise & Vibration Left Unaddressed

What goes wrong

Installers assume noise complaints are “normal.”

In reality, noise usually comes from:

-

Unlevel equipment

-

Rigid duct connections

-

Incorrect blower speed

-

Poor isolation

How to avoid it

-

Level pads and platforms

-

Use flexible connectors

-

Verify airflow and fan settings

A properly installed system should fade into the background.

8️⃣ 🛠️ Blocking Service & Maintenance Access

What goes wrong

Air handlers installed so tightly that:

-

Panels can’t be removed

-

Filters are hard to access

-

Electrical components are buried

This leads to:

-

Skipped maintenance

-

Higher service costs

-

Shorter equipment life

How to avoid it

-

Respect minimum service clearances

-

Plan filter access intentionally

Quality installation standards treat serviceability as mandatory—not optional.

👉 https://www.acca.org/standards

9️⃣ 🧾 Skipping Permits & Inspections

What goes wrong

Homeowners are told:

“Permits aren’t necessary for replacements.”

This can cause:

-

Failed home sales

-

Insurance issues

-

Missed safety violations

How to avoid it

-

Confirm who pulls the permit

-

Expect inspections where required

-

Keep documentation

🔟 📋 No Startup Testing or Homeowner Education

What goes wrong

The system is turned on, and the installer leaves.

No:

-

Airflow verification

-

Temperature checks

-

Thermostat walkthrough

-

Maintenance explanation

How to avoid it

-

Expect startup checks

-

Ask how to operate and maintain your system

Samantha rule:

If no one explains your new system, the install isn’t finished.

🚩 The Most Common Installer Phrases That Should Trigger Questions

Be cautious when you hear:

-

“That’s close enough.”

-

“We always do it this way.”

-

“The factory charge is fine.”

-

“Call us if there’s a problem.”

Good installs prevent problems instead of reacting to them.

✅ Samantha’s Field-Tested Error-Prevention Checklist

Before signing off, confirm:

-

✔ Proper sizing method used

-

✔ Ductwork evaluated

-

✔ Placement supports airflow & service

-

✔ Refrigerant evacuation verified

-

✔ Electrical & drainage done to code

-

✔ Noise and vibration addressed

-

✔ Permits handled

-

✔ Startup testing completed

If something feels rushed or unexplained, pause.

🏁 Final Thought: Most HVAC Problems Are Preventable

What makes these installation errors frustrating is that none of them are rare—and none of them are inevitable.

They happen when:

-

Planning is rushed

-

Shortcuts are normalized

-

Homeowners aren’t informed

When you know what to look for, you don’t need to hover or micromanage. You just need to ask the right questions at the right time.

Comfort isn’t luck.

It’s the result of avoiding the mistakes that too many installs quietly accept.

Buy this on Amazon at: https://amzn.to/47usZUk

In the next topic we will know more about: Can You Really Install a 4-Ton HVAC System Yourself? Pros, Cons & Safety