When it comes to commercial HVAC systems, the choice isn’t just about cooling—or even heating—it’s about reliability, cost-efficiency, maintenance, and how the system fits into your building’s structure and operations. I’m Jake, your trusted facilities manager neighbor, and I’ve helped outfit everything from small retail spaces to mid-sized offices with smart, budget-conscious HVAC solutions.

Best 6-10 Ton Commercial Packaged Air Conditioner and Gas Furnace Units

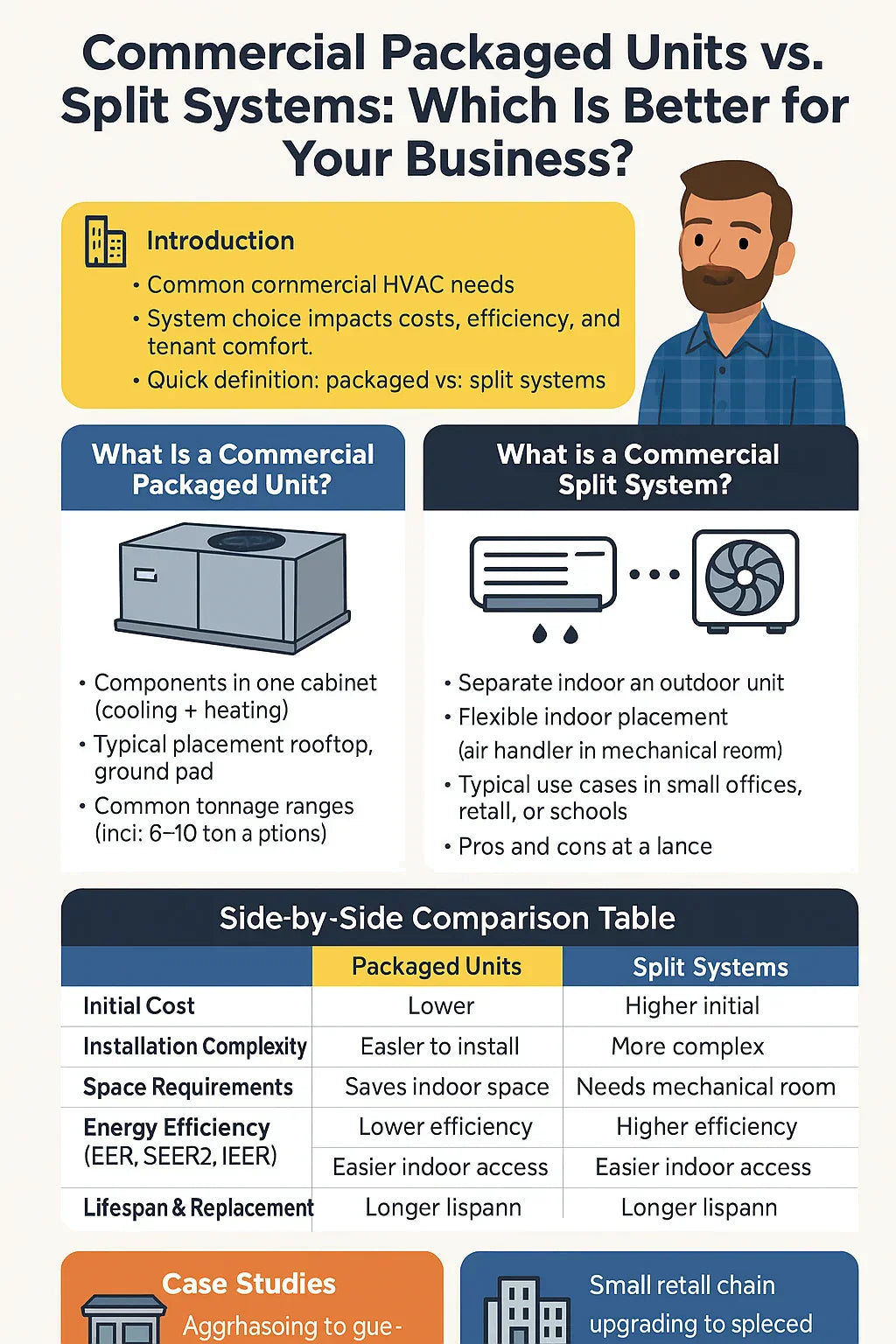

In choosing between commercial packaged units and split systems, you'll weigh trade-offs across space, noise, lifespan, energy use, and installation complexity. Ready to unpack it all? Let’s dive in.

Overview:

-

Packaged Units: All key components (compressor, condenser, evaporator, and optionally heating) housed in a single cabinet—usually rooftop or ground-installed.

-

Split Systems: Components are separated—compressor and condenser outdoors, evaporator and blower indoors. They connect via refrigerant lines.

I’ll walk you through direct comparisons, cost breakdowns, use-case scenarios, and my curated decision checklist to figure out what's best for your specific business needs.

Packaged Units vs. Split-Systems: Which HVAC Solution is Best for You?

1. What Are Packaged Units?

Definition & Layout

Packaged units are self-contained HVAC systems where refrigeration, heating (gas or electric), and airflow components are all integrated into one outdoor cabinet. These are commonly installed on rooftops or ground-level pads adjacent to the building.

Why They Work for Commercial Spaces

-

Space-Saver Design: Ideal for buildings with limited indoor mechanical room space.

-

Simplified Installation & Servicing: With everything together, setup is generally faster and maintenance is centralized.

-

Lower Initial Cost: Fewer components and less labor often mean lower upfront spend.

-

Quieter Indoors: Because noise-generating components are external, indoor quiet is improved.

Drawbacks

-

Lower Energy Efficiency: Standard SEER2 ratings often between mid-teens—split systems can exceed 20 SEER.

-

Exposure to Weather: All components are exposed, increasing wear and potentially shortening lifespan.

-

Limited Zoning Flexibility: Typically serves a single zone unless additional dampers or configuration added.

Packaged Units vs Split AC Systems: Pros and Cons

2. What Are Split Systems?

Definition & Structure

Split systems divide the HVAC process between two units: one indoor (evaporator coil + blower) and one outdoor (compressor + condenser), connected by refrigerant lines and often linked to ductwork.

Why Split Systems Appeal to Businesses

-

Higher Energy Efficiency: Many exceed 20 SEER, making them more economical to run.

-

Better Zoning & Flexibility: Ideal for buildings needing different temperatures per area (e.g., offices, server rooms, retail floors).

-

Customization & Expandability: Indoor units, smart thermostats, IAQ accessories, etc., can be added or upgraded down the line.

Considerations

-

More Complex Installation: Involves indoor component setup, running refrigerant lines, ventilation considerations—more labor and coordination

-

Higher Upfront Cost: Additional labor and dual-unit purchase typically increase initial investment

-

Indoor Noise Potential: While the compressor stays outside, indoor blower noise may require sound mitigation in sensitive environments.

Packaged vs. Split HVAC Systems: Which One Is Better?

3. Side-by-Side Comparison Table

| Feature | Packaged Units | Split Systems |

|---|---|---|

| Installation Cost | Lower—self-contained, less labor | Higher—dual components, refrigerant line routing |

| Energy Efficiency | Moderate (13–16 SEER) | High (up to 20+ SEER) |

| Zoning Capability | Limited without modifications | Excellent—add zones, control each independently |

| Indoor Noise | Very quiet indoors | Slight blower noise, condenser remains outdoors |

| Maintenance Access | One unit, easier access but rooftop can be tricky | Indoor & outdoor access, may require two-point service |

| Lifespan | Typically 10–15 years | Typically 15–20 years |

| Flexibility | Low—less customizable | High—future upgrades or expansions possible |

| Space Requirements | Minimal indoors | Requires indoor mechanical space |

4. Cost Analysis: Budget vs. Efficiency

Packaged units often cost 20–30% less to purchase and install, thanks to their single-unit nature. Split systems require indoor unit infrastructure and refrigerant line installation.

High-efficiency split systems pay off over time with energy savings. If electricity costs are elevated, higher SEER units ease operating budgets.

Maintenance Savings:

Packaged units benefit from simplified parts replacement and quick servicing. However, if rooftop access is difficult, service calls can be longer or costlier. Split systems may require more frequent checks but easier access may lower labor fees.

ROI Example (Hypothetical):

-

Packaged: ₹800/kWh, SEER 14, energy cost ₹1,000,000 annually.

-

Split: SEER 20, yields ~30% savings → ₹700,000 annual cost.

Over five years, a ₹1,500,000 extra upfront outlay on splits would break even and then start yielding net savings.

5. Climate & Application Scenarios

Hot, Dry Climates (e.g., Delhi summers):

Packaged rooftop units weather the conditions well—no indoor heat gain and simple duct connections. Just ensure shade, rooftop protection, and regular condenser cleaning.

Mixed or Cold Regions:

Split systems often pair better with modern heat pumps or gas furnaces indoors—more efficient heating and flexibility with hybrid systems.

Small Retail / Flat-Roof Buildings:

Packaged gas-electric units maximize rooftop space use and simplify service—favorite for compact footprints.

Multi-Zone Offices or Mixed Use:

Split systems shine here—control individual space temps, accommodate new zones, and support smart controls.

6. Maintenance & Serviceability

Packaged Units:

-

All service in one location.

-

Filter, coil, electrical checks centralized.

-

Roof access can be hazardous—roof protection and regular UV inspections needed.

-

Exposure means more wear—protective tarps or coatings help.

Split Systems:

-

Indoor units easier to access.

-

Outdoor units at ground level generally simplify service.

-

Refrigerant leaks between units must be carefully monitored.

-

Indoor blower noise might need acoustic treatments.

Jake’s Pro Tips:

-

For rooftops installing HVAC, always ensure structural load capacity plus a 25% safety margin.

-

Use quick disconnects and access doors on rooftop units to make maintenance safer and faster.

-

On split systems, label refrigerant runs and provide dedicated HVAC access panels indoors.

7. Real-World Use Cases

1. Baker’s Retail Outlet (Low Ceiling, Small Footprint): Packaged Unit

Flat-roof allowed for easy 8-ton rooftop unit. Space saved indoors, service done from roof hatch. Cost-effective and functional.

2. Multi-Floor Office Complex: Split System

Individual zones per floor with separate indoor units allowed temperature tailoring and energy optimization—plus flexibility for future expansion.

3. Mixed-Use Building with Server Room: Hybrid Approach

Main areas served by packaged rooftop zones for cost; sensitive server suite cooled via dedicated split system. Balanced CAPEX and precise control.

8. Decision Checklist: What Should You Choose?

-

Indoor space constraints? → Packaged unit saves indoor real estate.

-

Zoning flexibility needs? → Split system allows fine control.

-

Budget pressure now vs. later? → Packaged is cheaper now; split may save more over time.

-

Noise sensitivity? → Packaged keeps noise outdoors.

-

Maintenance access issues (e.g., rooftop safety)? → Split gives ground-level convenience.

-

Building climate? → Hot/dry: packaged works well; mixed/cold: split often more efficient.

-

Future expansion or smart upgrades? → Split is more modular.

-

Operational life expectancy? → Split potentially lasts longer with proper maintenance.

9. Final Wrap-Up

For Jake the facilities manager, the choice between packaged units and split systems hinges on balancing startup budgets against long-term efficiency and flexibility. Packaged units offer a no-nonsense, compact solution when indoor space is at a premium and upfront costs are tight. Split systems are smarter over the long haul—modular, efficient, and ready for expansion.

No universal answer exists. The best fit depends on your building’s layout, your climate, your budget structure (CAPEX vs. OPEX), and your comfort with maintenance access. Lean into lower upfront costs with packaged systems—or invest in future savings and granular control with splits.

Need tailored numbers for your building’s size, or want a downloadable comparison PDF for your board or contractors? Just holler—Jake’s got your back.

In the next topic we will know more about: How Much Does a 6–10 Ton Packaged AC & Gas Furnace Unit Cost in 2025?