One of the first questions homeowners ask me isn’t about SEER2 ratings or system tonnage—it’s:

“Mark, will this thing even fit in my basement/closet/attic?”

And that’s a good question. Because while the Goodman 2.5 Ton 13.8 SEER2 Northeast System (GLXS3BN3010 condenser + AMST30BU1300 air handler) is designed to work in a variety of home layouts, not every utility space is created equal.

If you don’t plan for clearance, airflow, and serviceability, you’ll end up with a noisy, inefficient system that’s a nightmare to repair later. I’ve seen plenty of jobs where someone “squeezed” a unit into a tight closet and three years later we had to rip drywall out just to replace a blower motor.

In this guide, I’ll walk you through real-world clearance requirements, placement tips, and space considerations to help you figure out whether a 2.5 Ton Goodman will work in your home.

📦 System Dimensions & Specs

First things first—you need to know the size of the equipment you’re working with.

Outdoor Condenser (GLXS3BN3010)

-

Height: ~35 inches

-

Width: ~29 inches

-

Depth: ~29 inches

-

Weight: ~160 lbs

Indoor Air Handler (AMST30BU1300)

-

Height: ~42 inches

-

Width: ~17.5 inches

-

Depth: ~21 inches

-

Weight: ~100 lbs

👉 These numbers can vary slightly by manufacturing batch, but they give you a ballpark. Always confirm with the model-specific spec sheet before install.

Goodman publishes system specs on their product resources page.

📏 Clearance Requirements

Outdoor Condenser

Goodman recommends:

-

12–18 inches clearance on all sides.

-

60 inches (5 feet) overhead clearance (no decks or eaves directly above).

-

Clear path for service access—don’t back it into a corner.

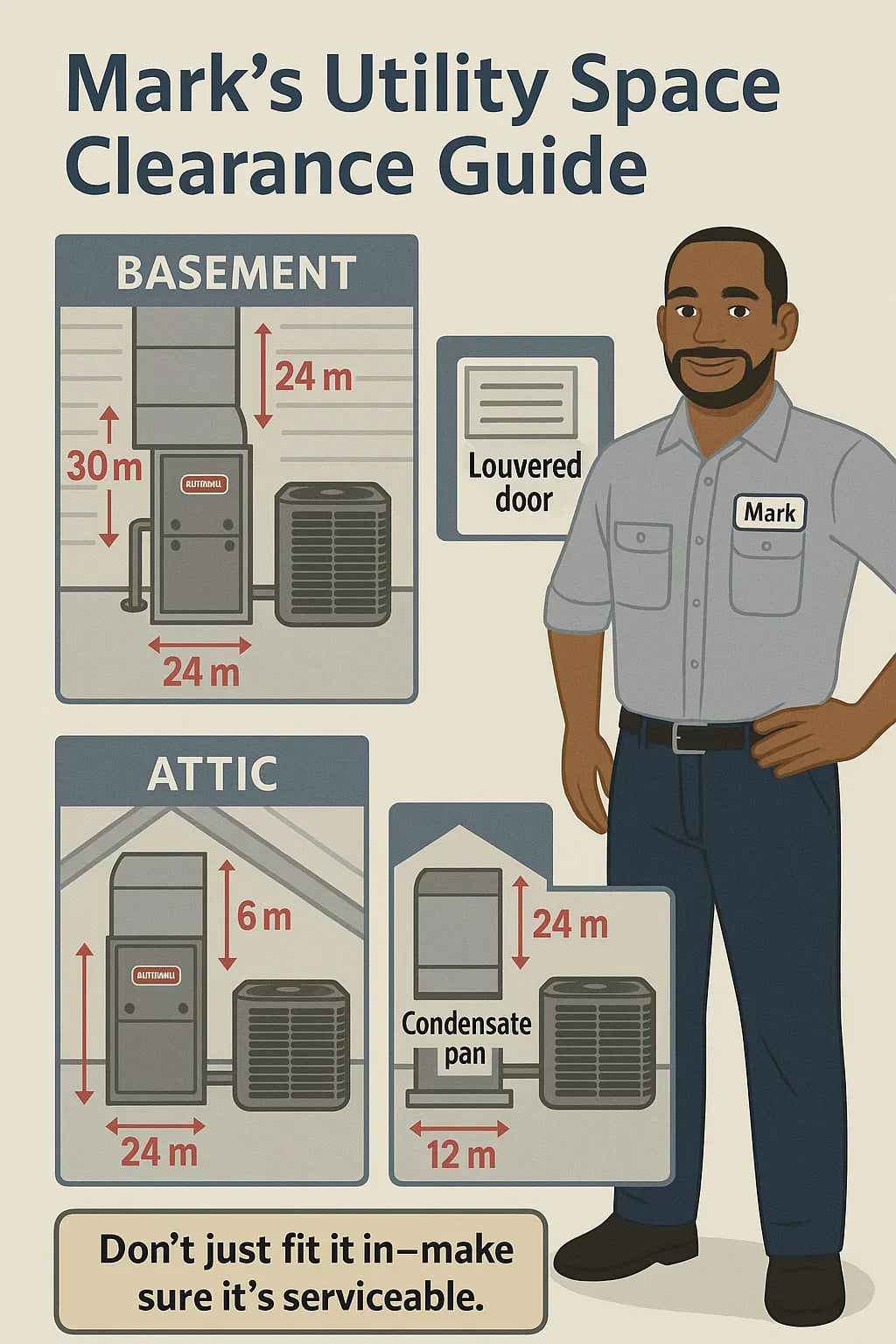

💡 Mark’s Tip: I always leave 24 inches on the service side (where the electrical panel is). Techs will thank you when it’s time to check pressures or replace a capacitor.

Indoor Air Handler

For the AMST30BU1300 air handler, you’ll need:

-

24 inches in front for service access.

-

Enough space on top or sides for supply and return duct connections.

-

Clearance for condensate drain routing.

ASHRAE guidelines on equipment clearance.

🏠 Basement Installations

A lot of Northeast homes keep air handlers in the basement.

Pros:

-

Easy access for service.

-

Naturally cooler space helps efficiency.

-

Easy routing for condensate drains.

Watch Out For:

-

Low ceilings: Make sure you have at least 7 feet clearance for safe service access.

-

Moisture: Basements can be damp. Elevate the air handler on a platform to avoid water damage.

-

Drainage: If no gravity drain is available, you’ll need a condensate pump ($200–$400).

👉 I’ve had installs where the system fit, but the homeowner didn’t account for clearance around beams or duct runs. Always measure basement headroom carefully.

🚪 Closet Installations

Closet installs are popular in smaller homes, but they can be tricky.

Requirements:

-

Return air ventilation: Closet doors must be louvered or include a dedicated return vent.

-

Combustion air (if furnace present): Ensure adequate airflow.

-

Service space: Leave 24 inches in front and at least 3 inches around sides.

Common Mistakes I See:

-

Drywall closets with no return vent → system starves for air.

-

Units jammed in so tight that techs have to cut drywall to service.

-

No drain access → clogged drain floods the closet.

💡 Mark’s Rule: If I can’t remove the blower motor without ripping walls, it’s not a good install. Always think “serviceability first.”

🪜 Attic Installations

Attic installs are common in the Northeast for homes without basements.

Pros:

-

Out of sight, out of the way.

-

Frees up closet or basement space.

Challenges:

-

Heat: Attics can reach 120°F+. Insulate ducts and air handler to prevent efficiency loss.

-

Access: Must have a proper walkway and service platform per code.

-

Drainage: Condensate pans with float switches are critical to avoid ceiling damage.

Building America guidance on attic HVAC placement.

🔇 Noise Considerations

Noise is often overlooked until the first hot night when the system kicks on.

Outdoor Condenser

-

Typical noise level: 72–76 decibels (about as loud as a running dishwasher).

-

Place away from bedroom windows or patios when possible.

Indoor Air Handler

-

In closets, vibration pads and sound insulation reduce noise.

-

Return air design plays a big role—undersized returns make the system louder.

👉 I always tell homeowners: a properly sized and balanced duct system makes a huge difference in noise levels.

Consumer Reports noise considerations for ACs.

🧮 Planning for Ductwork

Don’t forget about the space ducts need.

-

Supply plenum: Must have room above or beside the air handler.

-

Return plenum: Needs clear airflow path—don’t squeeze it against a wall.

-

Transitions: Allow space for smooth duct transitions, not cramped “bends.”

Poor duct design = higher static pressure = system wear and poor comfort.

🛑 What Happens If You Ignore Clearance

I’ve been called to service jobs where clearance wasn’t considered:

-

Basement install: No clearance in front → blower motor change required cutting pipes.

-

Closet install: No return vent → system iced up constantly.

-

Outdoor unit under deck: Air recirculated into itself, leading to compressor failure.

👉 Skipping clearance to “make it fit” always costs more in the long run.

📊 Real-World Fit Examples

-

1,600 sq. ft. ranch, Albany, NY: Basement install, plenty of clearance → easy access, smooth running.

-

1,400 sq. ft. townhouse, Boston, MA: Closet install → required custom louvered door for return air.

-

2,000 sq. ft. Cape Cod, Hartford, CT: Attic install → needed extra insulation and dual condensate safety switches.

💰 Cost Considerations for Clearance Adjustments

-

Closet modifications (louvered doors, drywall work): $300–$800

-

Condensate pump install: $200–$400

-

Attic platform + drain pan: $500–$1,000

-

Duct modifications for clearance: $500–$1,500

HVAC installation cost averages.

🧰 Mark’s Pro Tips

-

Leave room for service. Always plan for blower removal, coil cleaning, and filter changes.

-

Think airflow, not just fit. Tight installs choke systems.

-

Plan for noise. Don’t put condensers under bedroom windows.

-

Follow code. NEC and local building codes have clearance rules for safety.

-

Consult your installer early. A site visit avoids surprises.

✅ Bottom Line: Fit Isn’t Just About Size

A Goodman 2.5 Ton 13.8 SEER2 system will fit in most Northeast homes—but whether it runs efficiently and lasts depends on clearance, airflow, and serviceability.

-

Basements: Best choice if you’ve got headroom and drainage.

-

Closets: Workable with proper return ventilation and space.

-

Attics: Fine if you insulate, add drainage protection, and allow service access.

👉 My installer advice: Don’t just make it fit—make it serviceable. That’s how you keep your Goodman running smooth for 15–20 years.

In the next topic we will know more about: Goodman vs. Carrier vs. Amana: Which 2.5 Ton System Fits Northeast Homes Best?