When Mark signed the lease on his first workshop space, he thought he had it all figured out. The location was right. The layout worked. The price fit his start-up budget.

There was just one problem.

It was freezing.

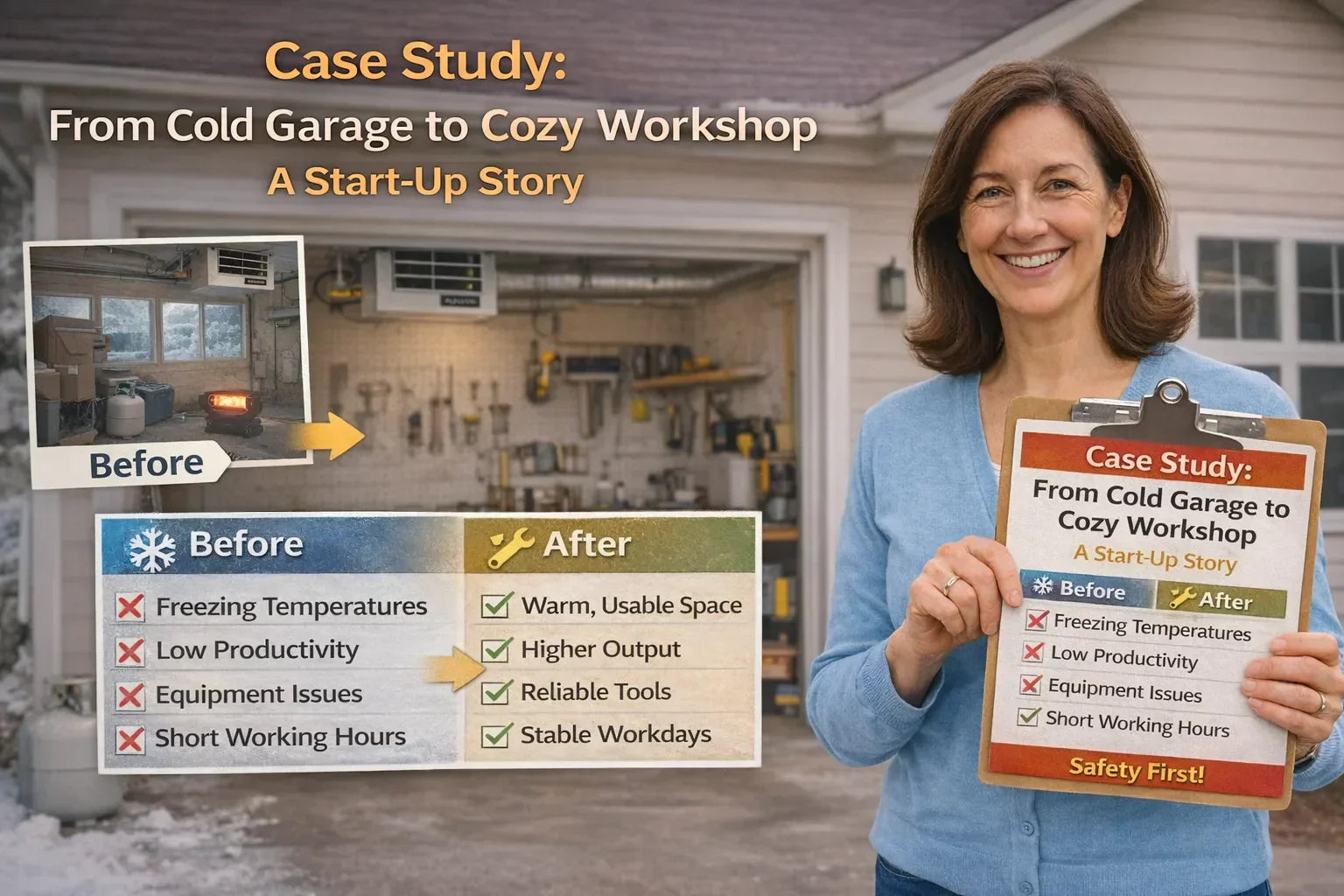

What followed is a story I see play out again and again with new space owners—a cold garage, rushed decisions, hard lessons, and ultimately, a smart heating setup that turned an unusable space into a productive workshop.

Reznor UDX 60,000 BTU Propane Unit Heater

This is Mark’s real-world start-up journey—and what other new business owners can learn from it.

❄️ The Starting Point: A Garage That Looked Better on Paper

On paper, the garage checked all the boxes:

-

Detached structure

-

High ceilings

-

Enough square footage for tools and inventory

-

Affordable rent

In reality, winter exposed the truth.

The initial problems:

-

Temperatures hovered near freezing

-

Tools felt stiff and unreliable

-

Working hours shortened drastically

-

Space heaters barely made a dent

Mark was burning time and morale before the business even gained traction.

🧠 The Wake-Up Call: Heating Isn’t Optional Infrastructure

At first, Mark tried to “get by.”

He used:

-

Portable electric heaters

-

Insulated clothing

-

Short work sessions

But productivity suffered. Projects took longer. Mistakes increased.

That’s when he realized something critical:

Heating wasn’t a comfort upgrade—it was core infrastructure.

📐 Step One: Understanding the Space (What Changed the Plan)

Before buying anything, Mark slowed down and assessed the space properly.

Key discoveries:

-

High ceilings meant heat loss was faster than expected

-

Garage doors leaked more air than walls

-

Square footage alone underestimated heating needs

This ruled out:

-

Residential space heaters

-

Wall-mounted electric units

The space needed business-grade heat designed for workshops.

🔥 Choosing the Right Type of Heater (Why Unit Heaters Won)

After researching options, Mark focused on ceiling-mounted propane unit heaters.

Why they made sense:

-

No floor space lost

-

Strong heat output

-

Fast warm-up times

-

Designed for garages and workshops

Propane also worked well because:

-

Natural gas wasn’t available

-

Propane offered installation flexibility

-

Fuel delivery fit his location

One option that matched his needs closely was the Reznor UDX 60,000 BTU propane unit heater.

💰 Budget Reality: Making It Work as a Start-Up

Mark didn’t have unlimited funds. Every dollar mattered.

How he kept costs in check:

-

Chose proper sizing (not oversized “just in case”)

-

Did space prep and mounting planning himself

-

Paid a pro only for gas connection and venting

He avoided the common trap of buying the cheapest unit—and instead focused on long-term operating cost.

🛠️ Installation Day: What Went Right (and Why)

Installation wasn’t rushed—and that made all the difference.

Key installation decisions:

-

Mounted the unit centrally for even airflow

-

Maintained proper clearances

-

Followed manufacturer venting guidelines

-

Installed a basic, reliable thermostat

Manufacturer guidance reference:

👉 https://assets.reznorhvac.com/download/70bf0584-5ed1-11ed-ae02-0016e1e579b9

Everything was tested before first ignition—not after something went wrong.

⚡ First Light & First Heat: The Turning Point

When the heater fired up for the first time, the difference was immediate.

Within minutes:

-

Air temperature stabilized

-

Cold corners disappeared

-

Tools felt usable again

-

The space finally felt “work-ready”

But the real impact showed up over time.

📈 The Results: What Changed After Heating Was Solved

Productivity

-

Longer work sessions

-

Fewer interruptions

-

Better focus

Equipment

-

Tools operated smoothly

-

Less moisture buildup

-

Reduced wear

Costs

-

Predictable monthly fuel expenses

-

No emergency heater purchases

-

Fewer lost workdays

Heating turned out to be one of the highest-ROI decisions Mark made early on.

🧯 Safety & Peace of Mind

Mark didn’t stop at heat alone.

He added:

-

Carbon monoxide detectors

-

Clear heater clearances

-

Seasonal inspection routines

General safety guidance:

👉 https://www.cdc.gov

This gave him confidence—not just warmth.

🌡️ Seasonality Lessons Learned

The first winter taught Mark valuable habits:

-

Pre-winter inspections matter

-

Steady thermostat settings save fuel

-

Vent checks after storms are critical

By the second winter, heater prep was routine—not reactive.

🚫 What Mark Would Do Differently (If Starting Again)

Mark admits he waited too long.

His biggest takeaways:

-

Don’t underestimate heat loss

-

Avoid temporary “fixes”

-

Install heating before winter hits

-

Treat HVAC as infrastructure, not an accessory

Those lessons saved him money later—but could’ve saved stress earlier.

🧩 What Other Start-Ups Can Learn from This Story

This case study highlights a pattern I see often:

Cold spaces don’t fail businesses overnight.

They quietly slow them down—day after day.

Start-ups that address heating early:

-

Work more consistently

-

Scale more confidently

-

Avoid emergency spending

🔚 Samantha’s Final Reflection

Mark didn’t just warm up a garage—he stabilized his business.

The moment his space became reliably heated, everything else improved:

-

Workflow

-

Equipment performance

-

Confidence

If you’re standing in a cold workshop right now, wondering if heating is worth the effort—this story is your answer.

Warm spaces don’t just feel better.

They work better.

And for a start-up, that makes all the difference.