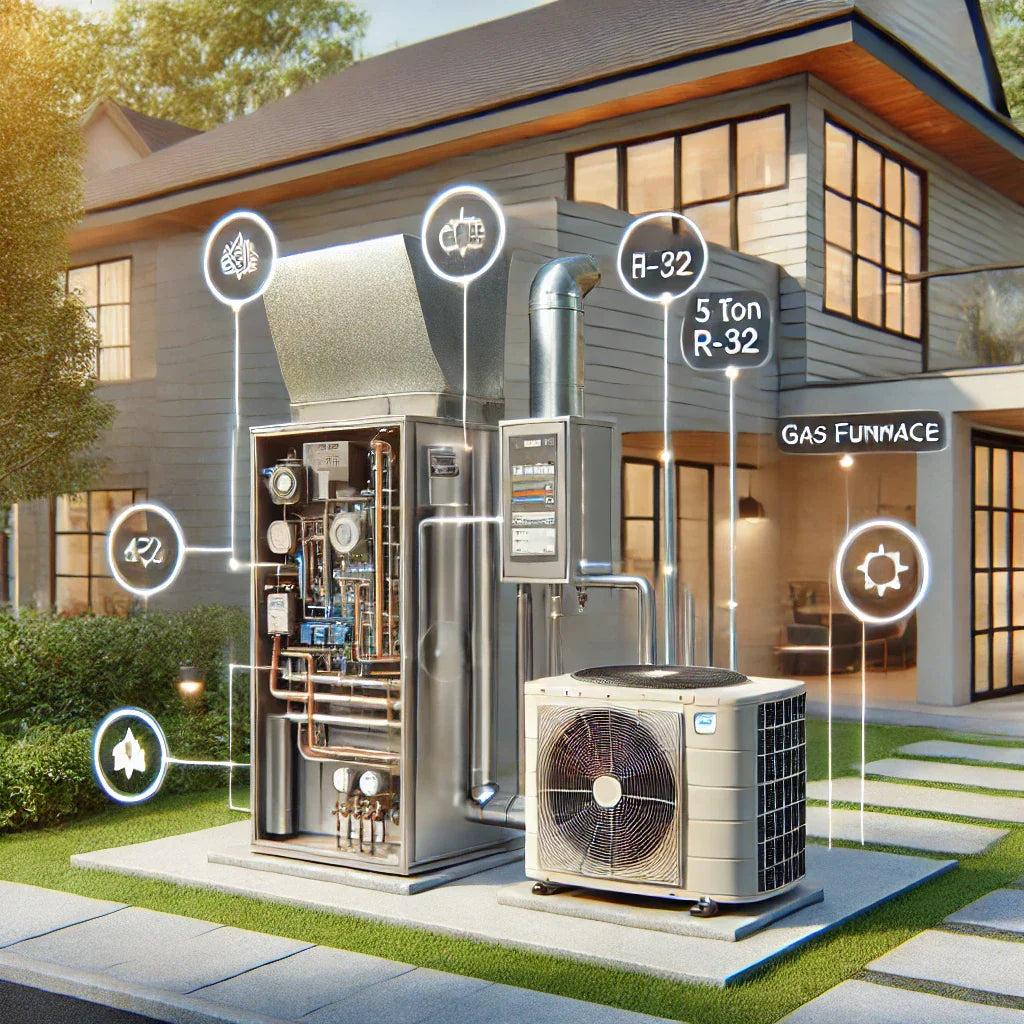

Case Studies: Successful Implementations of 5-Ton R-32 AC and Gas Furnace Systems

The HVAC industry is evolving rapidly, with a strong emphasis on energy efficiency, environmental sustainability, and compliance with modern regulations. One significant advancement is the integration of 5-ton air conditioning systems using R-32 refrigerant, paired with high-efficiency gas furnaces. This combination offers substantial benefits in terms of performance, cost savings, and reduced environmental impact. In this article, we explore several case studies that highlight the successful implementation of these systems, providing insights into their real-world applications and advantages.

Understanding Key Components

Before delving into the case studies, it's essential to understand the primary components involved:

-

5-Ton AC Systems: The term "5-ton" refers to the cooling capacity of the air conditioning system. One ton equals 12,000 BTUs (British Thermal Units) per hour, so a 5-ton system can remove 60,000 BTUs of heat per hour, making it suitable for large residential or commercial spaces.

-

R-32 Refrigerant: R-32 is a next-generation refrigerant known for its low Global Warming Potential (GWP) and high energy efficiency. Compared to traditional refrigerants like R-410A, R-32 offers better heat transfer properties and requires a smaller refrigerant charge, contributing to overall system efficiency.

-

SEER2 Ratings: The Seasonal Energy Efficiency Ratio 2 (SEER2) measures the cooling efficiency of air conditioning systems over a typical cooling season. Higher SEER2 ratings indicate greater energy efficiency and lower operating costs.

-

Energy Efficiency: Modern gas furnaces paired with R-32 AC systems often boast high Annual Fuel Utilization Efficiency (AFUE) ratings, indicating efficient fuel usage and reduced energy consumption.

-

Regulatory Standards: Organizations like ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) and the EPA (Environmental Protection Agency) provide guidelines and regulations to ensure HVAC systems meet safety, efficiency, and environmental standards.

Case Study 1: Residential Upgrade in Ohio

Background: A homeowner in Ohio sought to replace their aging HVAC system with a more energy-efficient solution.

Implementation: The chosen system was a 5-ton Goodman unit featuring R-32 refrigerant and a high-efficiency gas furnace with a 96% AFUE rating. The AC unit boasted a SEER2 rating of 13.4, aligning with modern efficiency standards.

Results:

-

Energy Savings: Post-installation, the homeowner reported a 25% reduction in monthly energy bills. Energy Star Energy Efficiency

-

Improved Comfort: The new system provided consistent indoor temperatures, enhancing overall comfort.

-

Environmental Impact: The use of R-32 refrigerant contributed to a lower carbon footprint.

Case Study 2: Commercial Installation in California

Background: A commercial facility in California aimed to upgrade its HVAC system to meet new energy efficiency standards and reduce operational costs.

Implementation: The facility installed a 5-ton R-32 AC system paired with a two-stage gas furnace. The system featured a SEER2 rating of 13.6 and an AFUE rating of 80%.

Results:

-

Operational Efficiency: The new system provided reliable performance, even during peak usage.

-

Cost Reduction: The facility observed a 20% decrease in energy expenses within the first year.

-

Regulatory Compliance: The installation met California's stringent energy efficiency regulations.

Case Study 3: Energy Efficiency Initiative in Multi-Family Housing

Background: A multi-family housing complex participated in an energy efficiency initiative aimed at reducing energy consumption and improving resident comfort.

Implementation: The complex replaced outdated HVAC systems with 5-ton R-32 AC units and high-efficiency gas furnaces.

Results:

-

Energy Reduction: The initiative led to significant energy savings across the complex.

-

Resident Satisfaction: Tenants reported improved indoor air quality and comfort levels.

-

Environmental Benefits: The use of R-32 refrigerant contributed to the complex's sustainability goals.

Regulatory and Safety Considerations

ASHRAE Guidelines: The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) emphasizes the responsible selection and management of refrigerants throughout their lifecycle. In their position document, ASHRAE advocates for a holistic approach to refrigerant selection, considering factors such as environmental impact, safety, and energy efficiency. The organization supports the transition to low-global warming potential (GWP) refrigerants like R-32 and promotes best practices in design, operation, and maintenance to ensure safety and environmental stewardship.

EPA Regulations: The U.S. Environmental Protection Agency (EPA) regulates the use and handling of refrigerants under Section 608 of the Clean Air Act. This includes requirements for technician certification, proper refrigerant recovery and recycling, and restrictions on venting refrigerants into the atmosphere. The EPA also maintains a list of acceptable refrigerants and their applications, ensuring that alternatives like R-32 meet safety and environmental standards.

Compliance with ASHRAE guidelines and EPA regulations is crucial for the safe and environmentally responsible implementation of HVAC systems utilizing R-32 refrigerant. Adhering to these standards helps minimize environmental impact, ensures occupant safety, and promotes the longevity and efficiency of HVAC equipment.