📌 Introduction: Is DIY PTAC Installation Realistic?

If you’ve ever stayed in a hotel, you’ve probably seen a PTAC (Packaged Terminal Air Conditioner) mounted under the window, quietly (or not so quietly) heating or cooling the room. These units are compact, self-contained, and designed for single-room climate control.

Because PTACs are modular and relatively easy to slide into a wall sleeve, many homeowners and small business owners ask me the same thing:

“Can I install a PTAC unit myself, or should I hire a pro?”

The short answer: Yes, you can install one yourself if you already have a wall sleeve and dedicated electrical line in place. But if you’re cutting a wall, adding new wiring, or want warranty protection, hiring a professional is the safer bet.

In this walkthrough, I’ll share:

-

The tools and materials you need

-

A step-by-step installation guide

-

Safety considerations you can’t ignore

-

A cost breakdown of DIY vs. professional installation

-

My personal pro tips to avoid common mistakes

🧰 1. What You’ll Need Before Starting

🛠️ Tools

-

Tape measure – to size the sleeve opening correctly

-

Level – ensures proper drainage slope

-

Power drill – for mounting hardware

-

Screwdrivers – Phillips and flathead

-

Caulking gun + weatherproof sealant – to prevent leaks

-

Utility knife – for trimming insulation and sealing foam

-

Safety goggles & gloves – non-negotiable for wall cutting and handling metal sleeves

📦 Materials & Accessories

-

PTAC Unit: ($700–$1,200 depending on BTU size)

-

Wall Sleeve: ($100–$200) – required if not pre-installed

-

Exterior Grille: ($50–$150) – protects condenser from debris

-

Drain Kit: ($25–$75) – ensures condensation doesn’t leak inside

-

Electrical Circuit: Usually a 208/230V dedicated outlet or hardwired line

👉 Browse compatible models at The Furnace Outlet PTAC Collection.

🏗️ 2. Pre-Installation Checklist

Before you even pick up a drill, go through this list:

-

✅ Room Size & BTUs: Confirm the PTAC capacity matches your room’s square footage. A common rule: 20 BTUs per square foot.

-

✅ Wall Thickness: PTAC sleeves typically fit 8–16 inch walls.

-

✅ Electrical Supply: Verify you have the correct voltage (often 208/230V). Plug-in units are easier; hardwired ones may need an electrician.

-

✅ Drainage Plan: Ensure condensation drains outside.

-

✅ Building Codes & HOA Rules: Some municipalities require permits to cut exterior walls.

👉 For sizing help, see ENERGY STAR Room AC Guide.

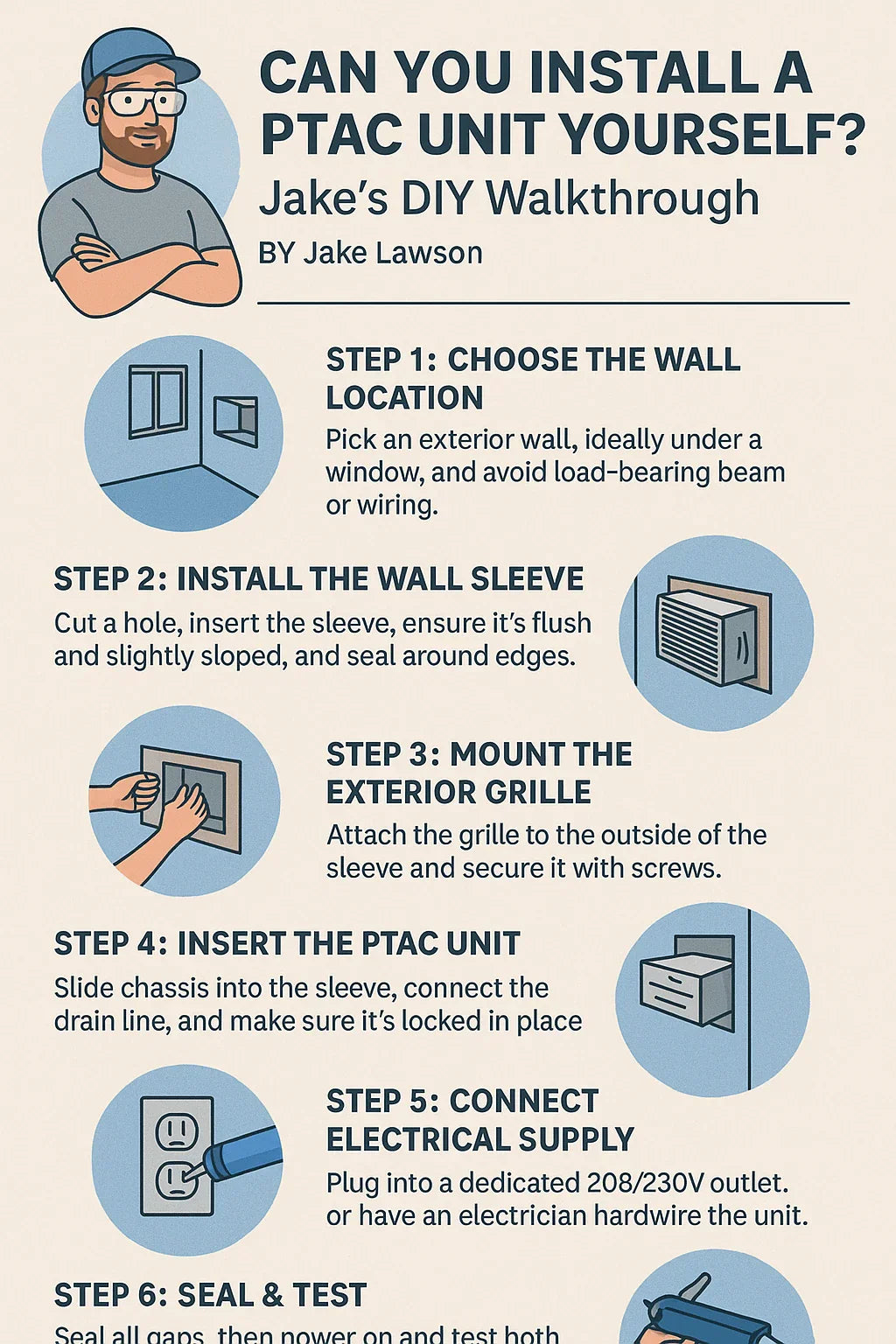

🧱 3. Step-by-Step Jake’s DIY PTAC Installation

🔎 Step 1: Choose the Wall Location

-

Select an exterior wall, preferably beneath a window for airflow balance.

-

Avoid cutting through load-bearing beams, plumbing pipes, or electrical wiring.

🔎 Step 2: Install the Wall Sleeve

-

Cut the Opening: Measure the sleeve dimensions carefully; cut slightly larger than the sleeve frame.

-

Insert Sleeve: Slide into the wall, ensuring a slight tilt to the outside (about 1/4 inch) for proper drainage.

-

Seal Edges: Use caulk to weatherproof the perimeter.

🔎 Step 3: Mount the Exterior Grille

-

Secure grille over the sleeve’s outdoor side.

-

Double-check that airflow isn’t obstructed by landscaping or objects.

🔎 Step 4: Insert the PTAC Unit

-

Slide the PTAC chassis into the sleeve until it locks into place.

-

Connect the condensate drain kit. Ensure tubing angles downward to avoid backflow.

🔎 Step 5: Connect Electrical Supply

-

Plug-in Units: Simply connect to a dedicated 208/230V outlet.

-

Hardwired Units: Requires running conduit and connecting to a breaker. ⚠️ If unsure, hire a licensed electrician.

🔎 Step 6: Seal & Test the System

-

Use foam or weatherstripping to close interior gaps.

-

Power on the unit. Test both cooling and heating modes.

-

Check for proper drainage and airflow.

⚡ 4. Safety Considerations

Even if you’re handy, PTAC installation involves risks.

⚡ Electrical Safety

-

PTAC units typically run on 208/230 volts—far more dangerous than 120V household outlets.

-

If you’re not experienced with high-voltage circuits, call an electrician.

🏗️ Structural Safety

-

Cutting a wall incorrectly can weaken the structure.

-

Always avoid studs, beams, and joists unless approved by a contractor.

💧 Water Safety

-

Poor drainage is the #1 DIY mistake. Without a proper slope, water leaks inside → mold, drywall damage, and expensive repairs.

👉 Review guidelines from the U.S. Department of Energy – Air Conditioner Safety.

🛠️ 5. DIY vs. Professional Installation

| Task | DIY Possible? | Pro Recommended? |

|---|---|---|

| Wall Sleeve Install | ✅ Yes | Sometimes |

| Exterior Grille Mount | ✅ Yes | Optional |

| Condensate Drain Setup | ✅ Yes | Optional |

| Electrical Hookup | ⚠️ Only plug-in | ✅ Hardwired |

| Warranty Compliance | ❌ Not always | ✅ Often required |

✅ Cost Comparison

-

DIY Install:

-

Unit: ~$900

-

Accessories: ~$200

-

Labor: $0

-

Total: ~$1,100

-

-

Pro Install:

-

Unit: ~$900

-

Accessories: ~$200

-

Labor: ~$350–$500

-

Total: ~$1,500–$1,700

-

💡 6. Jake’s Pro Tips for DIY Success

-

Measure Twice, Cut Once: Wall sleeves must be perfectly level to prevent drainage issues.

-

Seal Everything: Use high-quality silicone caulk around the sleeve—air leaks kill efficiency.

-

Use a Drain Kit: Don’t rely solely on sleeve slope; drain tubes ensure proper water removal.

-

Plan the Electrical First: Don’t buy your PTAC until you confirm your home has the correct voltage.

-

Keep the Manual Handy: Manufacturer diagrams are lifesavers when it comes to wiring and mounting.

📊 7. Cost & Time Investment Breakdown

| Category | DIY Cost | Pro Install Cost |

|---|---|---|

| PTAC Unit | $900 | $900 |

| Wall Sleeve + Grille | $175 | $175 |

| Drain Kit | $50 | $50 |

| Labor | $0 | $350–$500 |

| Electrical Setup | $0 (if plug-in) | $200–$400 extra |

| Total Investment | ~$1,125 | ~$1,600–$1,800 |

| Time Required | 4–6 hrs | 2–3 hrs (pro) |

🧼 8. Maintenance After Installation

Once installed, keeping your PTAC running smoothly is crucial.

-

Clean Filters: Every 30–60 days

-

Vacuum Coils: Seasonally

-

Clear Drain Lines: Monthly during cooling season

-

Pro Service Check: Once per year

👉 See HVAC.com – PTAC Maintenance Tips.

🏡 9. Real-World Scenarios

-

Rental Property: I installed PTACs in a duplex—did sleeves & drainage DIY, but hired an electrician for wiring. Saved ~$800 total.

-

Home Office Addition: With a pre-installed sleeve, I slid in a heat pump PTAC in under 3 hours.

-

Small Business Office: Paid for pro installation to meet warranty requirements—worth it for peace of mind.

📌 Conclusion: Should You DIY or Hire a Pro?

Installing a PTAC yourself is totally doable if:

-

You already have a sleeve installed

-

Your electrical line is ready

-

You’re confident in sealing and drainage work

But if you need wall cutting, new wiring, or want full manufacturer warranty protection, it’s smart to call a pro.

💡 Jake’s Takeaway: A hybrid approach often works best. Do the sleeve and prep yourself, then let an electrician handle the high-voltage wiring.

Expect a total investment of $1,100 DIY vs. $1,600–$1,800 professional install.

In the next topic we will read more about: Do PTAC Units Work in Winter? Understanding Electric Heat vs. Heat Pump Models