🏡 1. Jake’s Story: The Weekend He Almost Installed His Own Heat Pump

When Jake Lawson, a Michigan homeowner and weekend DIY enthusiast, bought his new Goodman 3 Ton 15.2 SEER2 Heat Pump System, he had a goal: save money by installing it himself.

After all, Jake had installed everything from ceiling fans to garbage disposals. How hard could a heat pump be?

“I figured I’d clear the space, hook up the lines, and have heat by Sunday,” Jake recalls.

“Then I learned about EPA licenses, refrigerant laws, and how one mistake could void a $10,000 system.”

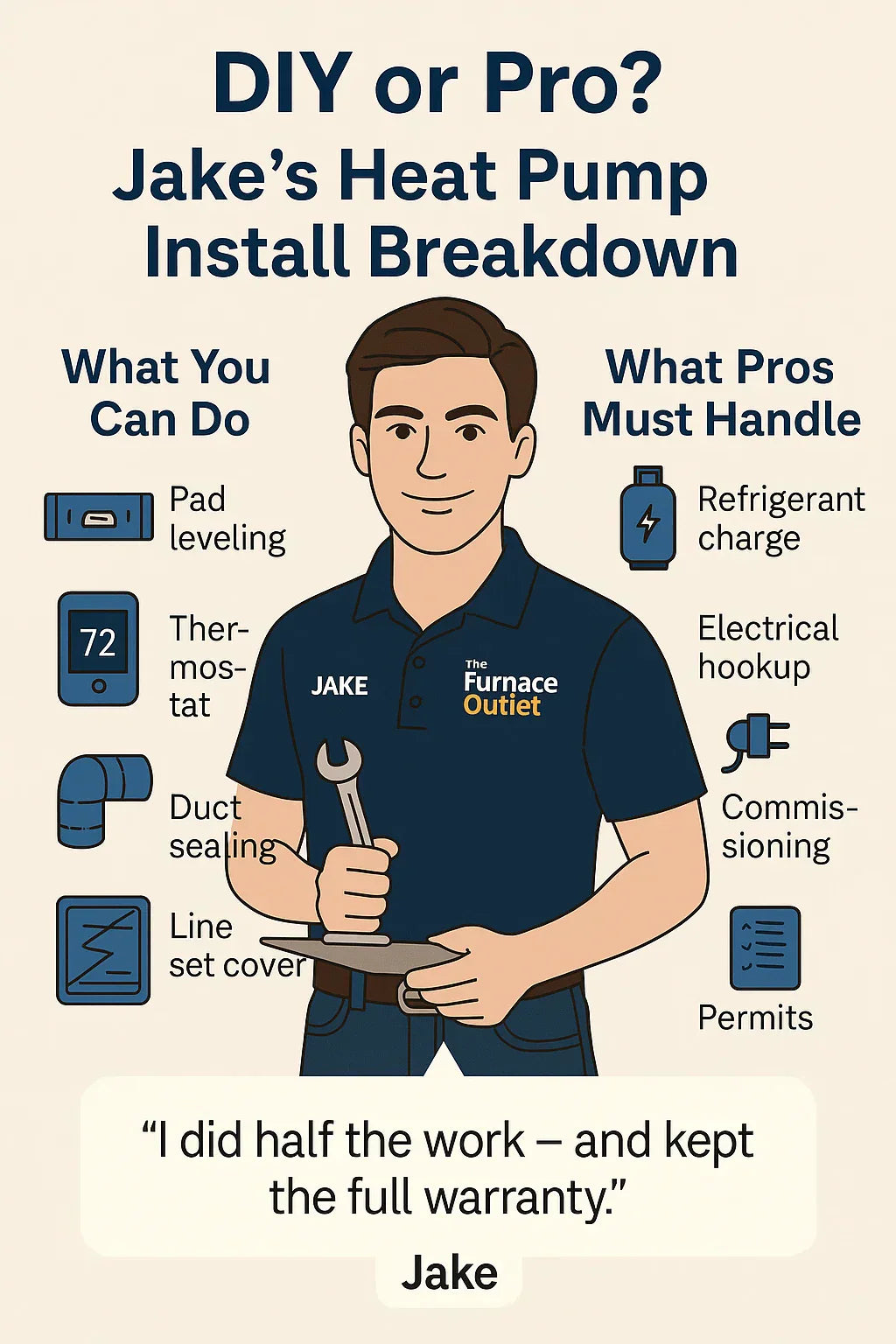

Jake’s experience isn’t unique. Many homeowners wonder if installing their own heat pump is worth the risk. The short answer? You can do a lot — but not everything.

This guide walks through what you can safely handle as a homeowner, what requires a licensed HVAC pro, and how Jake saved money and kept his Goodman warranty intact.

⚙️ 2. Why Heat Pump Installation Isn’t Like Other DIY Projects

Installing a heat pump isn’t like swapping out a water heater or laying new flooring. It involves three disciplines at once — electrical, refrigerant, and airflow engineering.

A single mistake (like overcharging refrigerant or wiring polarity incorrectly) can lead to:

-

Compressor failure

-

Refrigerant leaks

-

Tripped breakers

-

Even home insurance issues

Jake says:

“I realized this wasn’t a simple ‘plug it in and go’ project. There are parts you can prepare — and parts only a pro should touch.”

📘 Reference: Energy.gov – Heat Pump Installation Guidance

🧩 3. What Homeowners Can Do Themselves

Jake still rolled up his sleeves. There are several key prep tasks homeowners can safely and legally perform before the technician arrives.

✅ 3.1. Site Preparation

-

Choose a level, shaded spot for the condenser (outdoor unit).

-

Maintain at least 12–18 inches of clearance on all sides.

-

Avoid roof runoff and snow buildup zones.

Jake used a pre-fab concrete pad, leveled it with gravel, and installed vibration pads.

✅ 3.2. Mounting a Wall Bracket or Base Stand

If your system sits above snow line or on uneven terrain, you can install a condenser stand or wall bracket using manufacturer specs.

“I measured twice, drilled once — and had the outdoor stand up in an hour,” Jake says.

✅ 3.3. Thermostat Wiring and Mounting

You can install a smart thermostat compatible with your Goodman system before the pro arrives. Jake used a Wi-Fi model with heat pump settings.

📗 Tip: Label your thermostat wires before disconnecting the old unit.

✅ 3.4. Ductwork Preparation

DIY duct tasks include:

-

Sealing gaps with mastic or foil tape (never cloth tape).

-

Adding insulation to accessible ducts.

-

Replacing dirty or undersized return filters.

✅ 3.5. Line Set Path Preparation

Drilling and running line set covers (the insulated refrigerant lines between indoor and outdoor units) can be done with care.

Jake pre-installed his covers, saving the installer almost an hour.

“I did the grunt work. The pro did the science.”

These simple tasks saved him about $500–$700 in labor.

🧰 4. What You Should Leave to the Professionals

Some installation steps are not DIY-eligible due to safety, warranty, and legal restrictions.

| Task | Requires License | Why It’s Not DIY |

|---|---|---|

| Refrigerant handling | ✅ EPA Section 608 | Legal restriction; high pressure + environmental risk |

| Electrical connection | ✅ Local permit | Must meet NEC and local code |

| Line set connection | ✅ | Requires torque accuracy and nitrogen pressure test |

| Vacuum pulling & leak testing | ✅ | Specialized tools; must reach <500 microns |

| Refrigerant charging | ✅ | Precision pressure & temperature control |

| System commissioning | ✅ | Calibration + airflow balance required |

Jake’s key takeaway:

“I stopped where the refrigerant started — and that decision probably saved my warranty.”

📘 Reference: EPA Section 608 Certification Overview

⚠️ 5. The Legal and Safety Side of HVAC Installation

Installing a heat pump involves compliance with federal and state laws, building codes, and manufacturer warranties.

-

EPA Section 608 Certification is required to handle or purchase refrigerants like R-32.

-

Local permits are mandatory for electrical hookups in most states.

-

Manufacturer warranties (like Goodman’s 10-year parts warranty) often become void if not professionally installed.

-

Incorrect installations can lead to home insurance claim denials in case of electrical or refrigerant damage.

📗 Reference: Goodman – Warranty Information

🧱 6. Jake’s Step-by-Step Prep Checklist

| Step | Skill Level | Jake’s Notes |

|---|---|---|

| Clear and level area for pad | Easy | “Use a level and crushed gravel for drainage.” |

| Mount stand or bracket | Moderate | “Follow weight and wind rating specs.” |

| Run line set covers | Moderate | “Plan your bends — refrigerant lines aren’t flexible.” |

| Install thermostat | Easy | “Turn off breaker first!” |

| Seal ducts | Moderate | “Mastic is messy but worth it.” |

| Add insulation | Easy | “Focus on the suction line hole.” |

Jake spent two weekends prepping everything. When the HVAC tech arrived, installation time dropped from two days to one.

🔧 7. R-32 Refrigerant: Efficient but Not for DIYers

Goodman’s new-generation systems use R-32 refrigerant — known for better performance and lower global warming potential (GWP 675 vs. 2,088 for R-410A).

However, R-32 operates at higher pressures and is mildly flammable (classified A2L).

Handling it requires certified tools and EPA-authorized recovery systems.

DIY mishandling can cause:

-

Overpressure damage

-

Flammable leaks

-

Compressor burnout

📙 Reference: Daikin – R-32 Safety & Handling Guide

“Once I read about R-32 pressure ratings, I was glad to let the pro handle that part.”

💸 8. Jake’s Cost Comparison: DIY vs. Pro Install

| Type | Typical Cost | Warranty | Risk Level |

|---|---|---|---|

| Full Professional Install | $4,500–$7,000 | Full (10-Year) | ✅ Lowest |

| Partial DIY (Jake’s Route) | $3,000–$5,000 | Full (with pro sign-off) | ⚠️ Moderate |

| Full DIY (Not Recommended) | $2,000–$3,500 | ❌ None | ❌ High |

Jake saved roughly $1,800 total doing all prep work himself while maintaining full warranty coverage.

“I didn’t touch the refrigerant lines, and Goodman still honored the full warranty — that was my peace of mind.”

🧠 9. How Goodman Systems Help DIYers

Goodman systems are designed with accessibility and serviceability in mind — even for homeowners who enjoy being hands-on.

-

Tool-free access panels for faster maintenance.

-

Clearly labeled wiring and color-coded terminals.

-

R-32 charge ports with pressure markings.

-

Vertical air handler (model AMST36BU1400) includes easy filter access and drain pan service.

“Everything was logically laid out. Even a DIYer could follow along safely with the prep.”

⚡ 10. Tools Jake Used

| Tool | Purpose |

|---|---|

| Level | Ensure condenser pad stability |

| Torque wrench | Mounting bracket tension |

| Cordless drill | Anchoring base stand |

| Hole saw | Routing line set through siding |

| Foil tape | Duct sealing |

| Digital thermostat | Programming and energy savings |

Jake purchased everything at his local hardware store for under $250.

🧰 11. Permits and Code Requirements

Before touching anything electrical or structural, Jake checked with his local building department.

Most municipalities require:

-

Electrical permit for 240V connection.

-

Mechanical permit for HVAC replacement.

-

Inspection before system activation.

Failing to pull permits can lead to fines or denied resale inspections.

📗 Reference: ICC – Residential HVAC Code Overview

“My inspector said half the DIY installs he fails are because the homeowner didn’t call before wiring.”

🧭 12. DIY Tasks After Installation

After the professional completed the refrigerant and electrical work, Jake handled the finishing touches:

-

Mounted line set covers neatly along the siding.

-

Installed weatherproof insulation around wall penetrations.

-

Programmed the thermostat’s heating/cooling schedules.

-

Cleaned up debris and verified condenser airflow clearance.

“I still got that satisfaction of finishing the job — just without the stress.”

🧪 13. Why Commissioning Matters

Commissioning is the process of testing and optimizing your system after install.

It ensures your Goodman heat pump operates at peak SEER2 efficiency.

Professionals perform:

-

Vacuum pressure check (<500 microns)

-

Refrigerant subcooling test

-

Airflow measurement (CFM)

-

Temperature differential check (ΔT)

-

Thermostat calibration

Without commissioning, efficiency can drop 20–30% — meaning higher bills and shorter system life.

📘 Reference: EnergyStar – Proper HVAC Installation

⚠️ 14. Common DIY Mistakes (and How Jake Avoided Them)

| Mistake | Consequence | Jake’s Prevention |

|---|---|---|

| Bending refrigerant line too tightly | Kinked line, refrigerant restriction | Left to pro |

| Skipping vacuum pull | Moisture in system, compressor damage | Pro handled |

| Cross-wiring thermostat | System short | Took photos first |

| Ignoring airflow clearance | Overheating | Maintained 18-inch gap |

| Failing to insulate suction line | Condensation leaks | Used Armaflex wrap |

“Knowing what not to do saved me more money than trying to do everything.”

💡 15. The Warranty Question: What Goodman Requires

Goodman warranties are generous — 10 years parts and compressor — but require proof of licensed installation.

DIY-only installs risk:

-

Denied claims on compressor or control board.

-

Voided labor coverage.

-

Loss of technical support.

Jake submitted his contractor’s invoice along with product registration, keeping his full warranty intact.

📗 Reference: Goodman – Warranty Registration

🔋 16. Jake’s Final System Setup

Jake’s home: 2,000 sq ft, Midwest climate.

System: Goodman GSZB403610 (15.2 SEER2, 8.1 HSPF2) with vertical air handler and dual-fuel furnace backup.

Results after first year:

-

Energy bills down 25%.

-

System runs quieter than his old unit.

-

Consistent comfort across all rooms.

🧠 17. For the Ambitious DIYer: What’s Safe to Practice

If you want hands-on experience without voiding warranties, start here:

-

Watch Goodman’s official installation tutorials.

-

Learn how thermostats communicate with heat pumps (O/B, Y, C wiring).

-

Replace filters quarterly and clean coils annually.

-

Understand defrost cycles and fan modes.

This knowledge helps homeowners communicate better with technicians and spot small issues before they grow.

🧾 18. Jake’s Full Cost & ROI Breakdown

| Item | Cost | Savings | Payback |

|---|---|---|---|

| Goodman 3 Ton System | $8,800 | — | — |

| Contractor Labor (partial) | $2,200 | — | — |

| Jake’s DIY Prep Savings | -$1,800 | — | — |

| Federal Tax Credit (25C) | -$2,000 | — | — |

| Energy Savings | — | $400/year | 4.5 years |

Jake’s total effective install cost: ~$7,200 after incentives, with full warranty and professional commissioning.

🌍 19. Environmental Bonus

Jake’s new R-32-based heat pump reduced his home’s CO₂ emissions by 30%, compared to his previous R-410A system.

That’s equivalent to planting 25 trees each year.

📘 Reference: Daikin – R-32 Environmental Impact

“It’s good knowing I’m helping the planet — and my wallet — at the same time.”

🧩 20. Jake’s Advice for Other Homeowners

“You don’t need to be a pro to be part of your HVAC project. You just need to know where your part ends.”

Jake’s approach — DIY prep, pro installation — strikes the perfect balance between cost, safety, and warranty protection.

He summarizes it in three steps:

-

Prep the site and wiring.

-

Hire a certified pro for refrigerant and electrical tie-ins.

-

Enjoy full efficiency, full warranty, and full satisfaction.

🏁 21. Final Takeaway

If you’re planning a new heat pump installation:

-

Be proactive.

-

Do the easy prep yourself.

-

Let licensed pros handle the rest.

You’ll save money, avoid risk, and keep your Goodman system running efficiently for decades.

In the next topic we will know more about: What Size Heat Pump Do I Need? How to Match Tonnage to Home Size