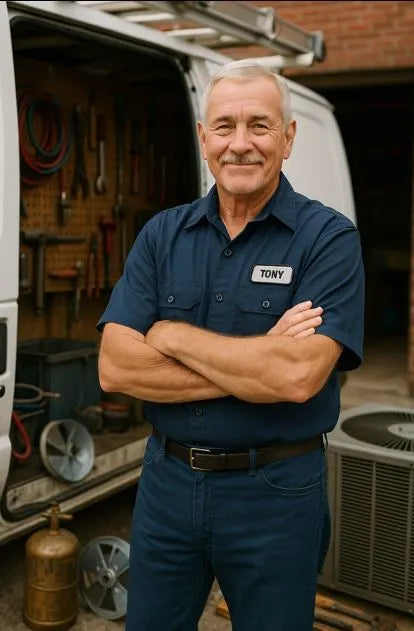

Annual Maintenance Checklist for the State ProLine XE — Tony’s Professional Plan

The Only Real Maintenance Guide You Need for Your 75-Gallon, 76,000 BTU Power Vent Water Heater

Let me be straight with you:

A State ProLine XE 75-Gallon 76,000 BTU Power Vent Gas Water Heater is a monster. It’s powerful, fast, durable, and built for heavy-duty homes that demand serious hot water output.

But even the best water heater in the world will fail early if you don’t maintain it — especially a power vent model.

Homeowners think:

“It’s new, it’ll be fine.”

“It’s a big tank, it won’t run out.”

“It’s gas, so it’s low-maintenance.”

Nope.

Not even close.

Power vent tanks have moving parts. They have sensors. They have fans. They have venting systems that deal with condensation. They have blowers that pull and push air. And a 76,000 BTU burner is not a toy — if you don’t keep it clean and clear, it’ll cost you real money and real headaches.

Today I’m giving you Tony’s Annual Maintenance Checklist, the same plan I follow for customers who want their tank to last 12–15+ years instead of dying early at 6 or 7.

This is the full professional-level breakdown — no fluff, no shortcuts, no nonsense.

Let’s get into it.

Why Annual Maintenance Is Non-Negotiable for Power Vent Units

You didn’t buy a basic atmospheric 40-gallon heater.

You bought a 75-gallon, high-BTU, high-output power vent beast.

That means:

-

The burner runs hotter

-

The blower runs frequently

-

The tank is under heavier thermal stress

-

The vent has to stay clear

-

Sensors need to stay clean

-

Condensation management matters

-

Recovery depends on combustion quality

Skipping maintenance on standard water heaters is bad.

Skipping maintenance on THIS water heater is a disaster.

Here’s a general water-heater-lifespan concept:

[Annual Maintenance and Service Life Correlation Notes]

Now let’s go step-by-step through your annual maintenance checklist — exactly how a pro like me handles it.

✔ Step 1: Perform a Full Sediment Flush (The Most Critical Step of All)

Sediment is the #1 enemy of every gas water heater.

If you only do ONE thing on this list, do this.

Sediment forms when minerals in your water supply fall out of suspension and settle on the tank bottom. For a high-BTU burner like this one:

-

Sediment cooks into a thick crust

-

That crust blocks heat transfer

-

The burner overheats

-

Recovery slows

-

Tank bottom flexes

-

“Popping” sounds happen

-

The tank’s lifespan shortens dramatically

And trust me: you don’t want to pay for a tank replacement because you skipped flushing.

Here’s a flushing-performance:

[Sediment Impact on Recovery Rate in Gas Water Heaters]

Tony’s Annual Flush Instructions:

-

Shut off gas and power

-

Connect a hose to the drain valve

-

Open a hot-water faucet

-

Drain 5–10 gallons

-

Close drain

-

Refill partially

-

Drain again

-

Repeat until water runs clear

For heavy-hardness areas? Flush twice a year.

✔ Step 2: Inspect and Clean the Blower Assembly

The blower is the heart of the power vent system.

Dust, bugs, lint, moisture, and even spider webs can enter the blower housing and reduce airflow. Reduced airflow = pressure switch failures and combustion issues.

Blower maintenance prevents:

-

Blower burnout

-

Poor venting

-

Ignition failures

-

Noise issues

-

Cycling problems

Here’s a power-vent-airflow:

[Blower Air Intake Efficiency Factors]

What Tony does annually:

-

Remove the blower cover

-

Vacuum dust

-

Clean intake grille

-

Check blower wheel for debris

-

Inspect for condensation

-

Tighten mounting screws

-

Lubricate only if manufacturer approves

If the blower starts sounding like a shop vac, it’s overdue for cleaning.

✔ Step 3: Clean the Flame Sensor (The Quickest Fix for Ignition Problems)

The flame sensor is a thin metal rod that tells the heater, “Yes, the flame is present.”

If it gets dirty, the heater thinks the flame is out — and it shuts off.

Symptoms of a dirty flame sensor:

-

Heater starts then shuts off

-

Repeated clicking

-

Random shutdowns

-

Intermittent warm water

-

Error codes

Tony’s cleaning method:

-

Turn off power/gas

-

Remove the sensor

-

Gently rub with steel wool or emery cloth

-

DO NOT sand hard

-

Reinstall the sensor

Here’s a sensor-performance:

[Flame Sensor Sensitivity and Combustion Reliability]

This is a 5-minute fix that solves half of all ignition complaints.

✔ Step 4: Inspect the Vent System for Slope, Blockage & Sagging

Power vent units exhaust horizontally through PVC.

That means the vent pipe deals with:

-

Condensation

-

Temperature changes

-

Weight

-

Physical strain

-

Material expansion

What Tony looks for:

✔ Correct slope (1/4 inch per foot toward the heater)

✔ Zero low spots (no dips allowed)

✔ No sagging between supports

✔ No snow, leaves, or debris blocking termination

✔ No birds nesting in vent cap

✔ Tight, sealed fittings

✔ No water stains or dripping

✔ No PVC cracks or UV degradation

Here’s a venting-best-practice:

[PVC Exhaust Slope and Support Standards]

Incorrect venting is one of the biggest causes of shutdowns in power vent systems.

✔ Step 5: Test the Pressure Switch

The pressure switch verifies that the blower is moving air correctly.

If the pressure switch is weak, sticky, or contaminated, the heater may:

-

Fail to start

-

Shut down mid-cycle

-

Throw error codes

-

Short cycle

-

Stop producing hot water

Annual testing is critical.

Tony’s test method:

-

Run heater

-

Verify switch closes

-

Check tubing for moisture

-

Inspect for cracks

-

Blow through tubing gently

-

Clean any blockages

-

Replace switch if readings are inconsistent

A pressure switch is cheap. Replacing it prevents expensive headaches.

✔ Step 6: Clean the Burner Assembly and Check Flame Quality

A 76,000 BTU burner needs to stay clean, unobstructed, and calibrated.

Dirty burners cause:

-

Weak flame

-

Slow recovery

-

Poor combustion

-

High CO output

-

Yellow flame

-

Soot buildup

-

Shortened heater life

What Tony checks:

-

Burner flame color (blue = good)

-

Flame height

-

Flame stability

-

Pilot flame shape (if applicable)

-

Burner port cleanliness

-

No spider webs or debris

-

No soot buildup

Here’s a flame-analysis:

[Gas Burner Flame Pattern and Combustion Efficiency Notes]

If your flame isn’t crisp, blue, and stable — the heater isn’t running efficiently.

✔ Step 7: Inspect the Anode Rod (Your Tank’s Lifesaver)

The anode rod sacrifices itself to protect the tank from corrosion.

If it’s fully used up?

Your tank starts rusting from the inside out.

Anode rods should be inspected every 2–3 years — annually if you have hard water.

Tony’s rule:

✔ Replace the anode rod BEFORE it hits 80% depletion

Not after.

Signs your anode needs replacement:

-

Heavy corrosion

-

Pitting

-

Rotten-egg smell in hot water

-

Discolored water

-

Slimy buildup

Anode rod failure is the #1 cause of tank death outside of sediment.

✔ Step 8: Check for Gas Leaks and Verify Gas Pressure

This water heater needs a strong, steady gas supply.

If pressure drops:

-

Flame becomes weak

-

Recovery slows

-

Burner cycles incorrectly

-

Heater shuts down

-

Energy usage increases

Annual checks:

-

Soap test for leaks

-

Check fittings and unions

-

Verify manifold pressure

-

Check regulator performance

-

Inspect flexible connectors

Gas supply is everything for a high-BTU burner.

✔ Step 9: Inspect the Thermostat and Control Board

The control board is the heater’s “brain.”

If it misreads temperatures or sensors, the heater will:

-

Overheat

-

Underheat

-

Short cycle

-

Fail to ignite

-

Deliver inconsistent water temps

Tony’s checks:

-

Verify temp calibration

-

Check wiring connections

-

Inspect board for corrosion

-

Reset memory where applicable

-

Confirm sensor accuracy

Control boards rarely fail suddenly — they fail gradually, and annual maintenance catches early issues.

✔ Step 10: Inspect All Water Connections for Leaks or Corrosion

A water heater can look fine from the front while quietly leaking in the back.

Annual inspection includes:

-

T&P valve

-

Cold-water inlet

-

Hot-water outlet

-

Dip tube connection

-

Drain valve

-

Anode port

-

Thermal expansion tank

-

Nearby copper pipe joints

A small leak turns into a major floor-and-wall repair quickly.

✔ Step 11: Test the T&P (Temperature & Pressure Relief) Valve

This valve is a safety device.

If it fails, pressure can build dangerously.

Testing it annually prevents:

-

Overpressure

-

Scalding water hazards

-

Tank deformation

Lift the lever gently. It should:

-

Discharge water

-

Seal shut again

-

Not drip after closing

If it leaks afterward, replace it.

✔ Step 12: Check the Condensate Drain Path (Often Overlooked)

Power vent systems generate a small amount of condensate.

Leaks, blockages, or poor routing cause:

-

Water around the heater

-

Rust

-

Mold

-

Sensor failures

-

Blower damage

This is one of the most overlooked maintenance items.

Make sure:

-

Drain line is clear

-

Drain port is clean

-

No blockages or kinks

-

No water pooling

✔ Step 13: Inspect the Vent Termination Outside

Even if your venting LOOKS fine inside, the termination may be clogged or blocked outside.

Look for:

-

Snow build-up

-

Insect nests

-

Leaves

-

Landscaping debris

-

Spider webs

-

Ice formation

This is extremely common in winter climates.

✔ Step 14: Listen for Unusual Noises

Every water heater makes some noise, but new noises are warnings:

-

Rattling = loose blower or piping

-

Rumbling = sediment

-

Whining = blower bearings going bad

-

Clicking = ignition struggles

-

Gurgling = condensation issues

Catching these early saves you money later.

✔ Step 15: Evaluate Overall Performance

At the end of maintenance, Tony always checks:

-

Does hot water reach fixtures quickly?

-

Are temperatures stable?

-

Is the flame strong and steady?

-

Is the blower smooth?

-

Are there any error codes?

-

Does recovery time match factory numbers?

You’re not just maintaining hardware — you’re maintaining performance.

Tony’s Final Verdict

If you follow Tony’s Annual Maintenance Plan, your State ProLine XE 75-Gallon Power Vent Water Heater will:

✔ Recover faster

✔ Run quieter

✔ Use less gas

✔ Avoid shutdowns

✔ Last 12–15+ years

✔ Deliver full capacity

✔ Stay safe and reliable

✔ Avoid expensive service calls

If you ignore maintenance?

Expect:

❌ slow recovery

❌ sediment buildup

❌ ignition failures

❌ blower breakdowns

❌ pressure switch problems

❌ gas inefficiency

❌ early tank death

A power vent heater is NOT “set it and forget it.”

It’s strong — but only if you take care of it.

This checklist is how professionals keep them running long after neglected units die.

In the next blog, we will know why hot water runs out too fast.