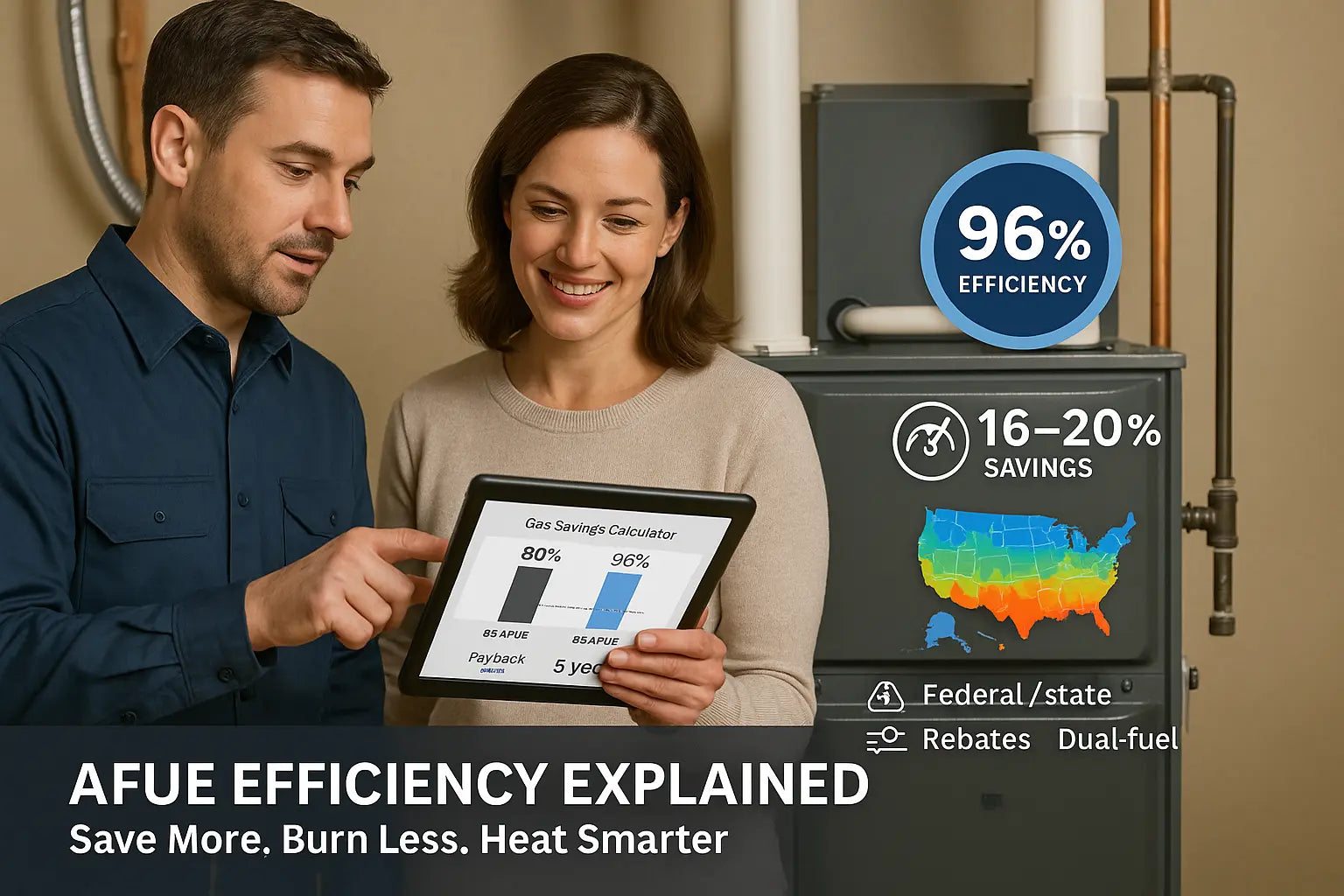

Upgrading from an 80 % single‑stage furnace to a 96 % AFUE modulating unit is one of the few HVAC moves that pays for itself while keeping customers warmer. Field data show a 16 – 20 % cut in seasonal gas consumption, yet the decision hinges on climate, gas rates, and available rebates. The guide below—built for contractors and savvy homeowners—dives into the engineering, economics, and installation details that separate brochure claims from real‑world performance.

AFUE 101: What That 96 % Really Means

Annual Fuel Utilization Efficiency (AFUE) expresses how much of every fuel dollar heats the living space versus escaping up the flue. An 80 % furnace burns $1 in gas and loses $0.20; a 96 % model wastes just $0.04. Multiply that delta by hundreds of therms each winter and the savings add up quickly.

The extra 16 % is unlocked by a secondary stainless‑steel heat exchanger that condenses water vapor (latent heat) before exhaust reaches 140 °F. Condensate drains must remain below 60 °F return air temperature to avoid re‑evaporation losses.

Crunching the 16 – 20 % Fuel Savings

If a customer’s winter gas spend is $1,000 on an 80 % unit, a straight‑line AFUE comparison predicts a $160 drop (to $840) after moving to 96 %. But lab math misses weather swings and house variables. Field audits across Minneapolis, Boston, and Sacramento show actual savings between 10 % and 20 % once insulation, window quality, and setback schedules are factored in.

|

Old AFUE |

New AFUE |

Typical Savings |

Winter Bill Before |

Bill After |

|

80 % |

96 % |

16 %–20 % |

$1,000 |

$800–$860 |

Advanced Tip: Model payback with “degree‑day‑weighted” runtime rather than calendar months. Pull HDD data for the last five winters, then multiply by appliance input rate and AFUE. The delta kBtu precisely equals terms saved.

Link your proposal to our live Design Center calculators, pros can plug in the customer’s ZIP and get instant degree‑day data plus gas‑rate look‑ups.

Modulating vs. Single‑Stage: Why Control Matters

A 96 % furnace alone won’t guarantee double‑digit savings—burner modulation and a variable‑speed ECM blower close the loop. Instead of cycling at 100 % or 0 %, a modulating valve fires anywhere from 35 % to 100 %, trimming overshoot and keeping return air above dew‑point for continuous condensing.

Static pressure above 0.8 in. w.c. forces the ECM to ramp up, negating part‑load efficiency. Commission with an external manometer; upsize supply trunks, or offer a matched R‑32 air handler to drop resistance.

Real‑World Payback Scenarios: 3 – 10 Years

The price delta between an 80 % and 96 % furnace hovers at $1,000 – $2,000. Without incentives, payback lands in the 6–10‑year range, roughly matching equipment life cycles. In colder zones or where gas tops $1.50/therm, breakeven drops under seven years.

Contractors closing a sale should present three scenarios in the quote:

-

Base 80 % replacement.

-

96 % upgrade without rebates.

-

96 % with stacked rebates .

Providing the math pre‑emptively builds trust—then let the customer choose the payback horizon that fits.

State & Federal Incentives That Change the Math

Rebates flip the script, cutting payback to 3–5 years in Massachusetts, New York, Minnesota, California, and Illinois. Programs such as Mass Save ($700 – $1,500) and NYS Clean Heat ($600 – $1,200) layer nicely with the $600 Federal 25C tax credit.

Direct homeowners to DSIRE (linked from our Help Center) to verify zip‑specific offers. If an IRA Home Energy Rebate is available, show the customer how combining it with a dual‑fuel packaged unit delivers both heating and cooling incentives.

Climate & Gas Rates: Hidden Multipliers

Heating Degree Days (HDD) and gas tariffs are the twin levers behind ROI. A 96 % AFUE furnace in Miami barely runs; in Duluth it clocks 2,500+ hours. Similarly, New England gas rates can double Midwest prices.

Advanced Calculation: Annual $ savings ≈ Input (Btuh) × Runtime (hours) × (1/AFUE_old – 1/AFUE_new) ÷ 100,000 × $ per therm.

Pros can overlay HDD maps with gas‑rate layers using NOAA and EIA data—bring a laptop to the kitchen table and let the numbers sell themselves.

For homes in temperate climates considering heat pumps, showcase our high‑SEER ductless mini‑splits to cover shoulder seasons, reserving gas heat for deep winter.

Installation Best Practices to Capture Every Percent

Even the best condensing furnace underperforms if venting or drainage is rushed. Maintain a minimum 3° slope on PVC vent runs back to the furnace to avoid pooled condensate. Use schedule‑40 only; thin‑wall pipe resonates and can violate local code.

Terminate intake and exhaust on opposite pressure zones whenever possible—stack effect wind can push exhaust into the intake, triggering flame rollout switches.

Commissioning Checklist: Fine‑Tuning for Peak AFUE

A five‑minute startup leaves efficiency on the table. Follow this condensed commissioning list:

-

Verify line voltage within ±5 %.

-

Clock the gas meter at high and low fire—adjust regulator to rated input.

-

Check flue temperature; aim for <120 °F exhaust at low fire.

-

Confirm 40–70 °F temperature rise.

-

Program thermostat with adaptive recovery to leverage modulation.

Record readings on the service tag so future techs can spot drift. For a comprehensive worksheet, download our free commissioning PDF.

When 96 % Isn’t Enough: Hybrid & R‑32 Options

Regions with >2,500 cooling HDDs may benefit more from integrated equipment. Pair a 96 % gas furnace with an R‑32 heat‑pump system to harvest cheap electric heat down to 25 °F, then hand off to gas below that setpoint. R‑32’s lower GWP (675 vs. R‑410A’s 2,088) future proof projects against refrigerant phase‑downs.

Wire the outdoor unit’s vapor‑line temperature sensor into the furnace IFC—this enables true dual‑fuel balance without third‑party thermostats.

Troubleshooting Efficiency Drop‑Off Over Time

After a few seasons, homeowners may complain the gas bill crept back up. Common culprits:

-

Partially blocked condensate trap raising flue temps.

-

Outdoor combustion‑air screen coated with lint.

-

ECM blower reverting to constant CFM after duct mods.

Log stack temperature with a Bluetooth thermocouple and trend it through the heating cycle. A 20 °F upward drift usually flags a condensate issue before flame sensor pitting begins.

Ready to Vet the Numbers on Your Next Project?

Whether you’re sizing a system for a 5‑ton retrofit or confirming rebate paperwork, our technical team answers the same questions every week:

-

What’s my exact payback at today’s gas rate?

-

Can I stack state and Federal incentives?

-

Should I use dual‑fuel instead of straight gas?

See our top-rated 96% AFUE furnaces at The Furnace Outlet, built for real gas savings.