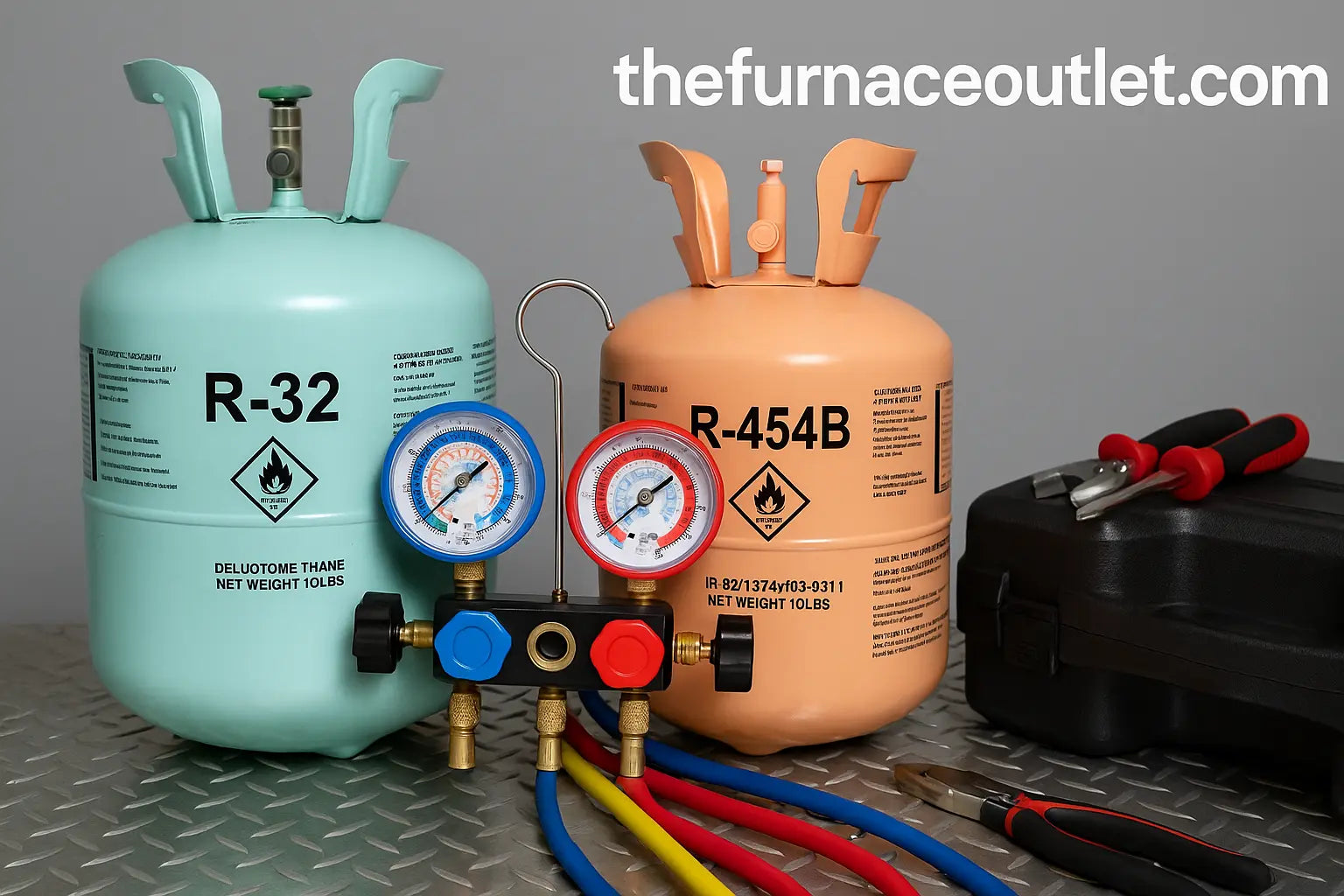

The HVAC landscape is undergoing a major transformation in 2025, driven by stricter environmental standards and the shift toward low-GWP refrigerants. At the forefront of this change are A2L refrigerants, particularly R-32 and R-454B—two alternatives designed to reduce global warming potential without sacrificing system performance.

But these advancements come with new responsibilities. For HVAC professionals, understanding and implementing safety protocols for A2L refrigerants isn’t optional—it’s critical. These refrigerants are mildly flammable, and while their environmental benefits are clear, handling them requires specialized training, strict safety compliance, and a proactive approach to risk management.

In this guide, we break down the essential safety protocols every HVAC technician should master in 2025 to work confidently and responsibly with A2L refrigerants.

Looking for systems that support R-32 refrigerants? Check out our full selection of R-32 Residential Air Conditioner Condensers.

Why A2L Refrigerant Safety Matters

The shift toward A2L refrigerants represents more than just a technical upgrade—it’s a redefinition of safety standards across the HVAC industry.

A2L refrigerants like R-32 and R-454B help reduce the environmental footprint of HVAC systems. But their mild flammability introduces new safety risks. These are not the same as traditional HFCs like R-410A. The job now includes more than performance—it’s about protecting technicians, clients, and the environment.

Safety protocols are designed to do just that. They offer a framework for navigating the hazards associated with flammable refrigerants—minimizing accidents, safeguarding property, and ensuring compliance with evolving regulations. As systems become more complex, these practices become essential tools for building trust, credibility, and long-term success in the HVAC field.

What Makes R-32 and R-454B Different

R-32 and R-454B aren’t just replacements—they’re next-generation refrigerants built for energy efficiency and reduced environmental impact.

-

R-32: With a GWP of 675, it performs better than R-410A in both efficiency and environmental safety. Its excellent thermodynamic properties help reduce system energy use, making it a popular choice for split systems and residential applications.

-

R-454B: With an even lower GWP of 466, R-454B is gaining traction as a direct replacement for R-410A. It balances efficiency with environmental performance and is already being adopted by major HVAC equipment manufacturers.

Both refrigerants are classified as A2L, meaning they are mildly flammable. This classification demands heightened awareness, new equipment standards, and additional safety procedures—all of which HVAC professionals must integrate into their day-to-day operations.

Explore cutting-edge R-32 Packaged Heat Pumps and R-32 Dual Fuel Packaged Units designed for advanced system compatibility.

Safety Requirements HVAC Pros Must Follow

Compliance is not just about avoiding fines—it’s about preventing incidents before they happen.

Industry groups like ASHRAE and the IEC have established guidelines to support safe A2L refrigerant use. These standards are designed to address the unique risks A2Ls pose, particularly when it comes to flammability and leak potential.

Key regulations include:

-

Proper Ventilation: Work areas must allow for safe dispersion of refrigerants. Poor airflow can lead to flammable concentrations building up—an unacceptable risk.

-

Leak Detection: Use of certified leak detection systems is required. These tools provide early warnings and help limit exposure, damage, or fire hazards.

-

Training and Certification: Technicians must be trained specifically on A2L handling, including emergency procedures and fire safety. General HVAC certification alone is not enough.

Understanding and applying these standards is key to safely integrating R-32 and R-454B into new systems.

Handling and Storage Guidelines You Can’t Ignore

Mishandling A2L refrigerants can lead to dangerous outcomes. Proper procedures for transporting, storing, and working with these refrigerants are non-negotiable.

-

Use Certified PPE: Flame-resistant clothing, gloves, and goggles are essential when working with flammable refrigerants.

-

Use Rated Equipment: All hoses, gauges, and recovery units must be specifically rated for use with A2Ls. Standard tools may not be safe or compliant.

-

Store Safely: Cylinders must be kept in well-ventilated, fire-safe areas away from ignition sources. Labeling must be clear and secure.

-

Secure Transport: Transport cylinders upright, use secure straps, and never expose containers to high temperatures.

A disciplined approach to handling and storage ensures both technician safety and regulatory compliance.

Equip your workspace with A2L-compatible HVAC Accessories, from gauges to hoses, to ensure compliance and safety.

Best Leak Detection Practices for A2Ls

Leak detection is more than just a maintenance task—it’s a frontline safety measure.A2L refrigerants can leak in small, hard-to-detect amounts, and when they do, the risks aren’t just environmental—they’re potentially explosive.

Best practices include:

-

Use A2L-Specific Detectors: Not all electronic leak detectors are equal. Make sure yours is calibrated for A2Ls to avoid false negatives.

-

Inspect High-Risk Areas: Joints, fittings, and valves are common leak points. Inspect regularly and keep detailed logs.

-

Emergency Readiness: In the event of a leak, act quickly. Evacuate the area, ventilate thoroughly, and isolate the system. Technicians should be trained to use fire extinguishers and administer first aid.

-

Document Every Incident: Logging leak events and responses is crucial for compliance, liability protection, and continuous improvement.

Being proactive with leak detection minimizes system downtime and keeps both people and property safe.

Training and Certification Are No Longer Optional

As A2Ls become the new standard, so too does the need for specialized technician training.

Certification ensures that technicians understand refrigerant behavior, know how to apply safety protocols in real-world settings, and are fully prepared to respond to emergencies.

Programs typically cover:

-

Chemical properties of A2Ls

-

Safe handling and charging practices

-

Emergency response

-

System design considerations for A2Ls

-

Equipment compatibility

Beyond initial certification, ongoing education is vital. Codes evolve. Tools improve. Staying current through workshops, manufacturer updates, or online courses ensures your skill set remains sharp and compliant.

Must-Have Tools and Equipment for Safe A2L Work

The right tools make a difference—not just in safety, but in performance and accuracy.

Key equipment includes:

-

A2L Leak Detectors: Designed specifically for flammable refrigerants, these provide fast and reliable results.

-

Flame-Resistant Hoses and Fittings: Lower risk of ignition during handling or charging.

-

Recovery Machines for A2Ls: Engineered to safely recover and contain flammable refrigerants.

-

Rated Gauges and Charging Tools: Accurate system monitoring helps prevent undercharging or overcharging—both of which can lead to system failure or safety risks.

Investing in purpose-built tools enhances technician safety and client trust.

Shop specialized HVAC Accessories built for safe refrigerant management.

Avoid These Costly Safety Mistakes

Even experienced HVAC pros can fall into common traps when working with A2Ls. Awareness is your best defense.

Mistake 1: Skipping ventilation checks.

Even mild refrigerant accumulation in a tight space can be hazardous.

Mistake 2: Using uncertified equipment.

Not all tools are compatible with flammable refrigerants. Using the wrong ones increases fire risk.

Mistake 3: Inadequate training.

General HVAC experience does not substitute for A2L-specific certification. Lack of proper training can lead to critical errors.

Mistake 4: Poor documentation.

Failing to log leak events or maintenance actions can lead to compliance issues and legal liabilities.

Avoiding these missteps helps safeguard lives, equipment, and reputations.

We’ve got your back with our Satisfaction Guarantee, Return Policy, and Lowest Price Guarantee to ensure your confidence in every purchase.

How HVAC Technicians Can Lead in the A2L Era

A2L refrigerants are here to stay. For HVAC professionals, this moment is an opportunity—not a challenge.

By adopting new safety protocols, updating tools, investing in ongoing education, and staying vigilant with handling procedures, technicians can not only comply with 2025 standards but lead the way in building a more sustainable HVAC industry.

Clients are looking for experts who understand the latest technologies and can deliver safe, eco-conscious service. By mastering A2L refrigerant protocols now, you’re setting yourself up for long-term success in an evolving market.

Take the Next Step Toward A2L Safety Mastery

Equip yourself with A2L-compatible systems, tools, and expert guidance.

Browse the full collection of HVAC systems and accessories engineered for 2025 safety standards.