Installing a high-efficiency system like a Goodman 14.5 SEER2 R-32 split system isn’t something that starts when the condenser comes off the truck. In my experience, the installs that go smoothly—and perform the way homeowners expect—are the ones where the real work started days (or weeks) earlier.

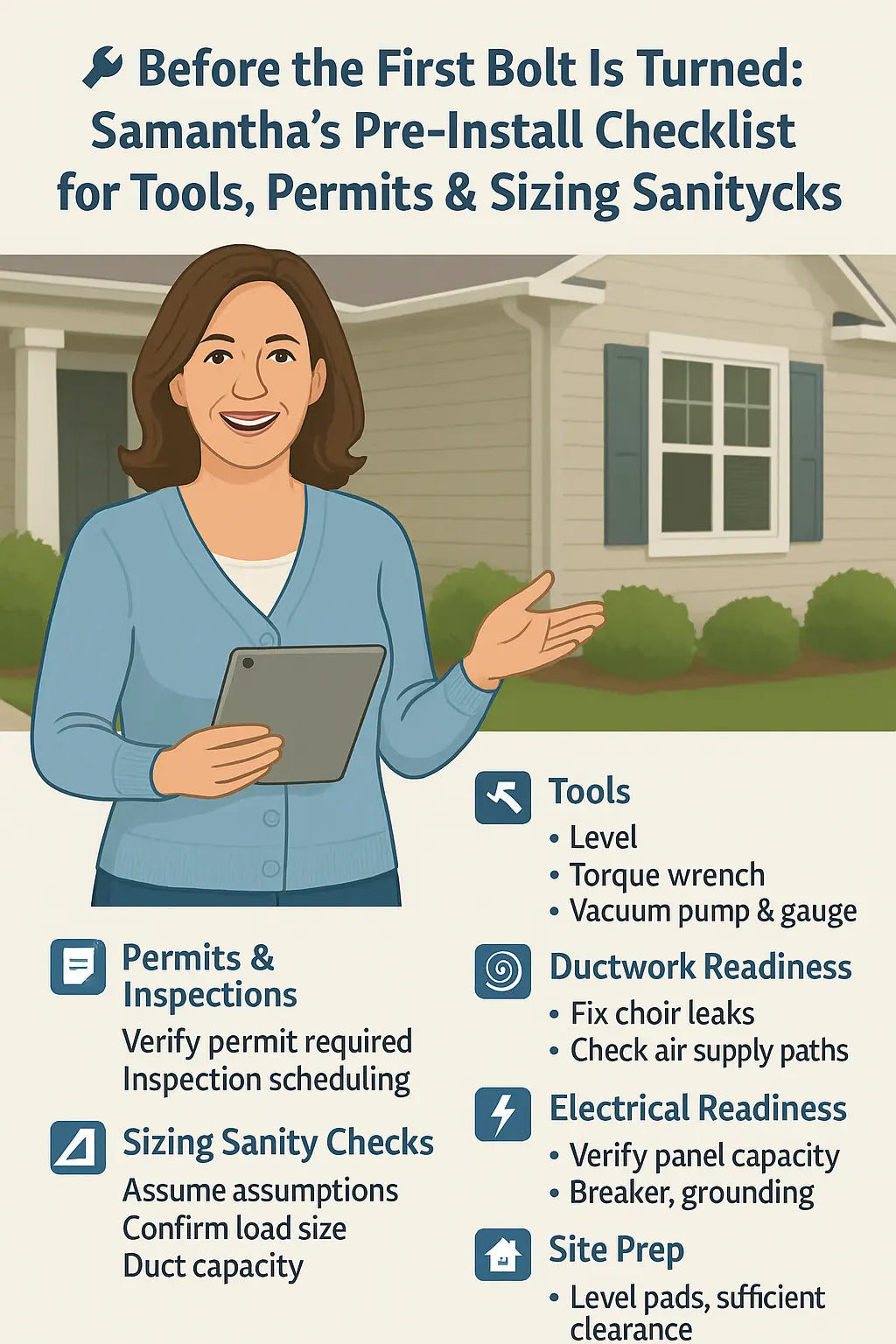

This guide is about that quiet, unglamorous phase before installation day: the tools, permits, prep work, and sizing checks that determine whether your system delivers comfort and efficiency…or headaches and callbacks.

If you’re a homeowner supervising an install, a serious DIYer, or just someone who wants to ask better questions, this is the checklist I wish more people had in hand before the first bolt is turned.

🧰 Step 1: Tools — What Actually Matters (and What Doesn’t)

Let’s start with a reality check. Not every install requires a garage full of specialty tools—but some tools are non-negotiable if you care about accuracy and safety.

Essential Tools for a Proper Install

These are the baseline tools that separate a “hook it up” job from a quality install:

-

Accurate level – For condenser pads and air handler positioning

-

Torque wrench – Prevents under- or over-tightened electrical and refrigerant connections

-

Vacuum pump & micron gauge – Required for proper evacuation before refrigerant charging

-

Manifold gauge set (rated for modern refrigerants)

-

Digital multimeter – For verifying voltage, amperage, and control signals

-

Sheet-metal tools & mastic – Because duct connections should be sealed, not just screwed together

Industry quality-installation standards emphasize proper evacuation, electrical verification, and sealed air paths because skipping these steps shows up later as efficiency loss or premature failure, not instant fireworks.

👉 ACCA’s Quality Installation principles outline why this matters:

https://www.acca.org/standards

Tools That Are “Nice to Have” (But Not Deal-Breakers)

-

Thermal camera or infrared thermometer

-

Static pressure manometer

-

Advanced airflow measurement tools

If your installer uses these, great. If not, they should at least understand airflow and pressure well enough to explain their setup decisions clearly.

Samantha tip: If no one on site can explain why they’re using a tool—or why they aren’t—you’re allowed to pause the process and ask questions.

🧾 Step 2: Permits & Inspections — The Unsexy Stuff That Protects You

Permits don’t make your house cooler. But skipping them can absolutely make your life harder later.

Why Permits Matter (Even If You “Trust Your Installer”)

-

They ensure electrical and refrigerant work meets local code

-

They create a paper trail for resale, insurance, and warranty claims

-

They trigger an inspection, which is an extra set of trained eyes on the install

In many areas, HVAC system replacements require permits for:

-

Electrical modifications

-

Refrigerant-handling equipment

-

New equipment placement (especially outdoor condensers)

Local requirements vary, but the U.S. Department of Energy is clear that proper installation and verification are part of ensuring equipment performs to its rated efficiency.

https://www.energy.gov/energysaver/air-conditioning

Questions I Always Ask Up Front

-

Who is pulling the permit—you or the homeowner?

-

Will there be an inspection, and when?

-

What documentation will I receive after sign-off?

If the answer to all three is vague, that’s a red flag—not necessarily a deal-breaker, but something to slow down and clarify.

📐 Step 3: Sizing Sanity Checks — Trust, but Verify

This is the step most homeowners assume has already been handled—and where I see the most expensive mistakes.

Why “Same Size as Before” Isn’t a Strategy

Homes change. Insulation improves. Windows get replaced. Ducts get modified. What worked 15 years ago may not be right today.

Proper sizing should consider:

-

Square footage and layout

-

Ceiling heights

-

Insulation levels

-

Window orientation and shading

-

Duct condition and design

The gold standard is a Manual J load calculation, which estimates the actual heating and cooling load of your home.

What Homeowners Can Reasonably Verify

You don’t need to run the math yourself, but you can ask:

-

Was a load calculation done recently?

-

Were any home upgrades factored in?

-

How does duct capacity support this tonnage?

Samantha reality check: Oversized systems don’t just waste energy—they short-cycle, struggle with humidity, and often feel less comfortable than properly sized equipment.

🌀 Step 4: Ductwork Readiness — The Silent Performance Partner

Your new system doesn’t operate in isolation. It’s only as good as the duct system it’s connected to.

Pre-Install Duct Questions That Matter

-

Are supply and return ducts properly sized for the new system?

-

Are there visible leaks, crushed runs, or disconnected joints?

-

Is the return path adequate, or is airflow being starved?

Even high-efficiency systems can lose a shocking amount of performance through leaky or undersized ducts. Field studies show that addressing duct issues is one of the fastest ways to recover lost efficiency and comfort.

https://www.energy.gov/energysaver/minimizing-energy-losses-ducts

What Should Happen Before Installation Day

-

Obvious duct leaks sealed

-

Return restrictions identified

-

Access issues resolved (attics, crawlspaces, closets)

If duct fixes are needed, it’s far better to know before the new system is sitting on the pad.

⚡ Step 5: Electrical Readiness — No Surprises at the Panel

Electrical mismatches are one of the most common causes of installation delays—and rushed decisions.

Electrical Checks to Confirm in Advance

-

Panel capacity and breaker availability

-

Correct breaker sizing for the condenser

-

Proper disconnect location outdoors

-

Grounding and bonding compliance

These checks protect both the equipment and your warranty. Improper electrical setup can lead to nuisance trips, component stress, or failed inspections.

The National Electrical Code (NEC) governs these requirements, and your installer should be working within those standards.

🏠 Step 6: Site Prep — Small Details, Big Impact

This is the step homeowners often underestimate, but it directly affects install quality and longevity.

Outdoor Unit Prep

-

Level, code-compliant pad

-

Adequate clearances for airflow and service

-

Drainage that won’t flood the unit base

Indoor Unit Prep

-

Clear access for removal and replacement

-

Adequate space for service panels

-

Planned condensate drain routing

When these details are handled in advance, installers can focus on precision—not improvisation.

🚩 Step 7: The Pre-Install Red Flag List

Before install day, I pause if I hear:

-

“We’ll figure that out when we get there.”

-

“That’s how we always do it.”

-

“Permits slow things down—we don’t really need them.”

Confidence is good. Assumptions are not.

✅ Samantha’s Final Pre-Install Checklist

Before anyone touches a wrench, I want “yes” answers to these:

-

Tools on site support proper evacuation, charging, and electrical verification

-

Permits and inspections are clearly defined

-

System sizing has been validated, not assumed

-

Ductwork is ready to support the new equipment

-

Electrical capacity has been confirmed

-

Installation sites are prepped and accessible

If all six boxes are checked, installation day becomes what it should be: efficient, calm, and predictable.

🏁 Final Thought: Installation Quality Starts Before Installation Day

High-efficiency systems don’t fail quietly—they fail expensively and frustratingly when prep work is skipped. Taking the time to handle tools, permits, prep, and sizing before installation protects your comfort, your investment, and your peace of mind.

This isn’t about being difficult or second-guessing professionals. It’s about being an informed homeowner who understands that the best installs are built on preparation—not luck.

Buy this on Amazon at: https://amzn.to/47usZUk

In the next topic we will know more about: How to Select the Perfect Location for Your Goodman Outdoor Condenser