Homeowners gravitate towards HVAC heat pumps for their unique ability to provide heating and cooling. Still, many people don’t realize that heat pumps cannot switch between the two modes without a crucial component known as the reversing valve.

Heat pumps are essentially air conditioners that work in two directions. Both systems use refrigerants, coils, and the same principle of heat exchange to control indoor climates. Air conditioners transfer heat in only one direction–out. Heat pumps, however, transfer heat in two directions, moving heat outside in summer and inside in winter.

Heat pumps utilize additional components to achieve the two-directional heat transfer. The reversing valve is fundamental to reversing the functions of indoor and outdoor coils and allowing heat pumps to provide heating and cooling to homes.

Upgrade Your Heating with Our Heat Pumps: Click to Explore!

What is a heat pump reversing valve?

An air source heat pump uses a reversing valve to control the refrigerant’s directional flow. The indoor and outdoor coils reverse their functions when the heat pump reversing valve routes the refrigerant’s flow in the opposite direction. This process changes whether heat transfers inside or outside the home.

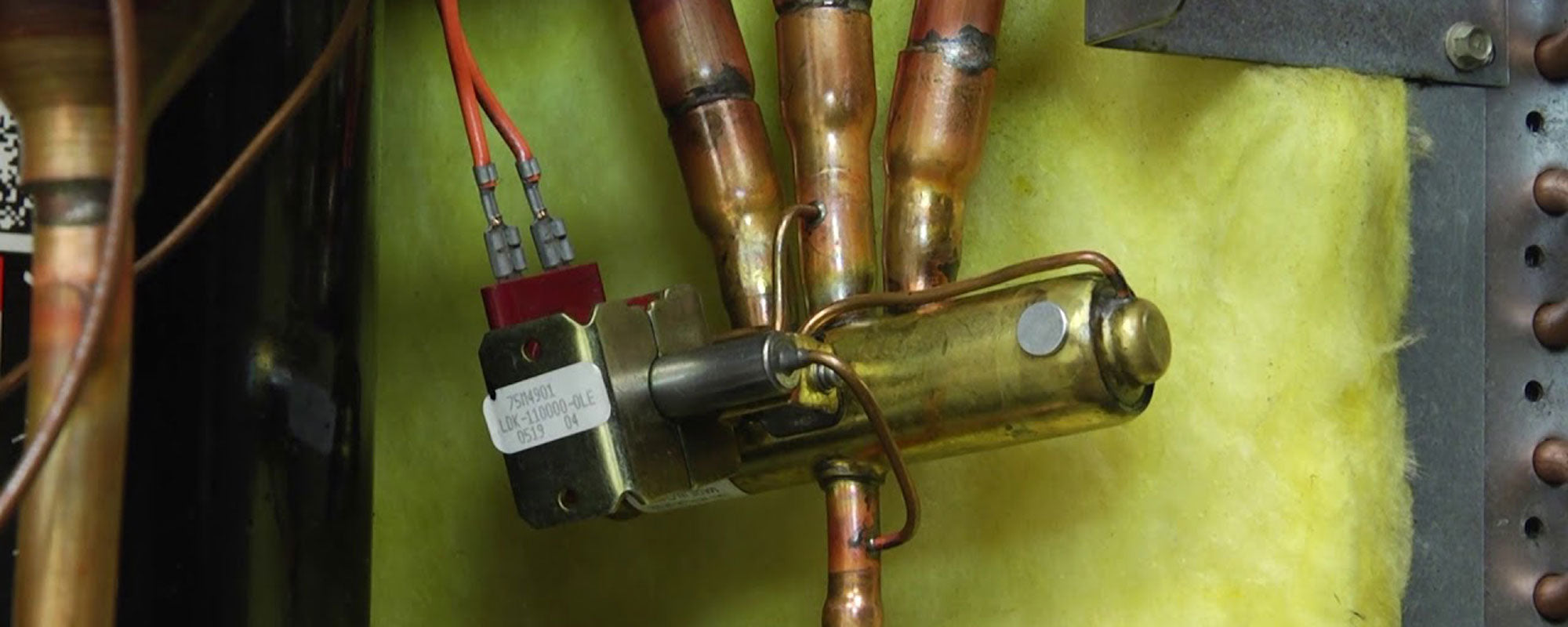

Where is the reversing valve on a heat pump?

The reversing valve on a heat pump system is typically located close to the compressor and soldered to the copper refrigerant tubing running through the unit. Replacing a reversing valve is a professional undertaking that involves soldering pipes and handling refrigerants. Homeowners can attempt to unstick a reversing valve.

How does a reversing valve work?

Reversing valves have two states, energized and de-energized. A solenoid supplies 24 volts to the reversing valve in the energized state. The manufacturer determines which action, heating or cooling, the heat pump performs in each state. Typically, heat pumps heat when de-energized form and cool when energized.

If you’re familiar with how a heat pump works, you know that heat pumps don’t generate heat; they transfer it. The refrigerant flows through the tubes connecting the indoor and outdoor components. The refrigerant absorbs heat at one of the system’s coils and expels it at the other. Whether the heat is transferred inside or outside depends on the heat pump’s mode and the direction of the refrigerant’s flow. The heat pump compressor pressurizes the refrigerant to push it through the system and allow it to release the heat it has absorbed. Expansion valves depressurize the refrigerant so it can absorb more heat.

Reversing valves are four-way valves, with one port at the top and three at the bottom. High-pressure refrigerant from the compressor flows into the valve’s top port via the discharge line. Low-pressure refrigerant from the indoor coil in cooling mode or the outdoor coil in heating mode flows from the valve’s middle-bottom port to the compressor via the common suction line. The reversing valve’s slide moves back or forth to divert the refrigerant from the compressor’s suction and discharge lines and reverse its flow. The ports on both sides of the common suction line are used for suction or discharge depending on the heat pump’s mode.

How to unstick a reversing valve on a heat pump?

The reversing valve might be stuck if the heat pump won’t switch between heating and cooling modes. If the valve appears to be stuck, attempt to restore it and verify the valve is functioning:

-

Clean the exterior

-

Test the solenoid

-

Check the capillaries

Clean the exterior

Dirt on the valve's exterior can penetrate its crevices and impede operation. Tap both sides of the valve with a hard plastic object, such as the handle of a screwdriver, to loosen any accumulations. Then, wipe the valve's exterior with a dry cloth. If the problem persists, test the solenoid and check the capillaries.

Test the solenoid

The solenoid's electrical charge and magnetism cause the valve to switch between modes. The heat pump won't change if the solenoid loses its charge or burns out:

-

Check for broken and loose wires around the valve.

-

Test the valve's charge using a voltmeter.

-

Test the solenoid's magnetization by touching it with a small screwdriver.

If the solenoid is not energized or magnetized, it must be replaced.

Check the capillaries

Inspect the valve’s four copper ports for damage. A partially blocked capillary will cause the valve to malfunction and require replacement.

How do you know if your reversing valve is bad?

Reversing valve issues are often confused with other heat pump problems, such as faulty compressors. Reversing valve replacement has a mid-range repair cost of $200 to $650. A bad reversing valve might exhibit these signs:

-

An inability to switch between modes

-

Diminished heating and cooling performance

-

Increased energy bills

Inability to switch between modes

The reversing valve’s internal components switch the heat pump between heating and cooling modes. The components might be stuck or faulty if the heat pump system stays the same from one operation to the other.

Diminished heating and cooling performance

Heat pumps are less effective at transferring heat when the parts are going bad. The reversing valve might be faulty if the heat pump system doesn’t control the home’s climate as well as usual. Professionals can identify and address these issues during annual heat pump maintenance service calls before they become significant problems.

Increased utility bills

Heat pumps are recognized as energy-efficient HVAC systems, but they are only efficient when operating correctly. A faulty reversing valve can reduce a heat pump’s efficiency and yield higher than average energy bills.

Upgrade Your Heating with Our Heat Pumps: Click to Explore!

Conclusion

The reversing valve is a crucial electric heat pump component that allows the system to switch between heating and cooling operations. Reversing valves have two states, energized and de-energized. The valve is typically energized during the cooling process. An electromagnetic solenoid causes the reversing valve’s slide to move and redirect the refrigerant’s flow when energized.

Reversing valve components can stick and affect its operation. Tapping both sides of the valve with a plastic screwdriver handle might restore it. The valve will be inoperable if the electromagnetic solenoid loses its charge or its capillaries are blocked. A faulty reversing valve prevents the heat pump from switching modes, diminishes its heating and cooling performance, and increases utility bills.

Only HVAC professionals should replace faulty reversing valves. The valves are components of the sealed refrigerant circuit, and proper procedures must be followed to recover and recharge the refrigerants and prevent refrigerant gas from escaping into the atmosphere.

Frequently Asked Questions

When is the reversing valve energized?

The reversing valve is typically energized in cooling mode, although some manufacturers (e.g., Rheem and Ruud) set the reversing valve to energize in heating mode.

What causes a reversing valve to stick?

A defective solenoid is the most common cause of a stuck reversing valve. A dirty valve and clogged capillaries might also cause a reversing valve to stick.

What causes a reversing valve to fail?

The most common causes of reversing valve failure are stuck valves, defective coils, and internal valve leaks.